Abstract

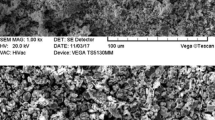

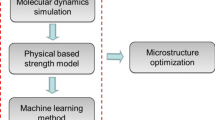

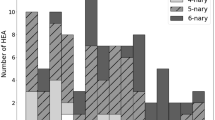

An equiatomic CoCrFeMnNi high entropy alloy (HEA) was prepared by the gas atomization process. In addition, high-energy milling was carried out to study the effects of milling parameters on the morphology and crystallographic properties of HEA powders. Phase identification and morphology of milled powders were observed by X-ray diffraction and scanning electron microscopy, respectively. Both the atomized and milled powders exhibited a single-phase face-centered cubic solid solution. The resultant crystallite size (CS) and lattice strain (LS) of milled HEAs were estimated using the Williamson Hall method and predicted using an artificial neural network (ANN) approach. With increasing the milling time from 0 to 240 min, the CS decreased from 39.7 to 6.56 nm and the LS increased from 0.25%–1.48%, respectively. Furthermore, the developed ANN modeling provides an excellent method for the prediction of the CS and LS with excellent accuracies of 96.25% and 93.43%, respectively.

Graphical Abstract

Similar content being viewed by others

Data availability

References

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014)

A. Sharma, H. Lee, B. Ahn, Met. Mater. Int. 28, 2216 (2022)

C. Nagarjuna, H.J. You, S. Ahn, J.W. Song, K.Y. Jeong, B. Madavali, G. Song, Y.S. Na, J.W. Won, H.S. Kim, S.J. Hong, Appl. Surf. Sci. 549, 149202 (2021)

J.W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006)

F. Otto, A. Dlouhý, Ch. Somsen, H. Bei, G. Eggeler, E.P. George, Acta Mater. 61, 5743 (2013)

C. Nagarjuna, J.W. Song, K.Y. Jeong, M.W. Pin, G. Song, J.K. Lee, Y.S. Na, H.S. Kim, K.B. Kim, S.-J. Hong, J. Mater. Res. Technol. 17, 1686 (2022)

W. Fu, K. Gan, Y. Huang, Z. Ning, J. Sun, F. Cao, J. Alloy. Compd. 872, 159606 (2021)

J.H. Kim, Y.S. Na, Met. Mater. Int. 25, 296 (2019)

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, H.R. Ammar, Met. Mater. Int. 26, 1099 (2020)

C. Nagarjuna, K.Y. Jeong, Y. Lee, S.M. Woo, S.I. Hong, H.S. Kim, S.J. Hong, Adv. Powder Technol. 33, 103519 (2022)

M.J. Chae, A. Sharma, M.C. Oh, B. Ahn, Met. Mater. Int. 27, 629 (2021)

S.K. Dewangan, V. Kumar, Int. J. Refract. Hard Met. 103, 105777 (2022)

S.K. Dewangan, S. Samal, V. Kumar, Mater. Today Commun. 27, 102356 (2021)

M.A. Alam, H.H. Ya, M. Azeem, M. Yusuf, I.A. Soomro, F. Masood, I.A. Shozib, S.M. Sapuan, J. Akhter, Crystals 12, 372 (2022)

T. Varol, A. Canakci, S. Ozsahin, Sci. Eng. Compos. Mater. 21, 411 (2014)

R. Jain, S.K. Dewangan, V. Kumar, S. Samal, Mater. Sci. Eng. A 797, 140059 (2020)

S. Choi, S. Yi, J. Kim, B. Shin, S. Hyun, Metals 11, 1559 (2021)

S.H. Joo, H. Kato, M.J. Jang, J. Moon, E.B. Kim, S.J. Hong, H.S. Kim, J. Alloy. Compd. 698, 591 (2017)

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, J. Alloy. Compd. 589, 61 (2014)

X. Liu, H. Yin, Y. Xu, Materials 10, 1312 (2017)

C. Wang, W. Ji, Z. Fu, Adv. Powder Technol. 25, 1334 (2014)

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, Z. Fu, Intermetallics 56, 24 (2015)

Y. Liu, J. Wang, Q. Fang, B. Liu, Y. Wu, S. Chen, Intermetallics 68, 16 (2016)

D. Yim, P. Sathiyamoorthi, S.J. Hong, H.S. Kim, J. Alloy. Compd. 781, 389 (2019)

H. Hadraba, Z. Chlup, A. Dlouhy, F. Dobes, P. Roupcova, M. Vilemova, J. Matejicek, Mater. Sci. Eng. A 689, 252 (2017)

Ł Rogal, D. Kalita, A. Tarasek, P. Bobrowski, F. Czerwinski, J. Alloy. Compd. 708, 344 (2017)

U. Benedetto, A. Dimagli, J. Thorac. Cardiov. Sur. 160, 183 (2020)

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT), 2021R1A2C1005478 (BA) and 2021R1A4A1031357 (BA). This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, 2022R1I1A1A01055105 (CN), 2022R1I1A1A01053047 (SKD), and 2021R1A6A1A10044950 (SKD).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nagarjuna, C., Dewangan, S.K., Sharma, A. et al. Application of Artificial Neural Network to Predict the Crystallite Size and Lattice Strain of CoCrFeMnNi High Entropy Alloy Prepared by Powder Metallurgy. Met. Mater. Int. 29, 1968–1975 (2023). https://doi.org/10.1007/s12540-022-01355-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01355-w