Abstract

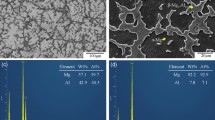

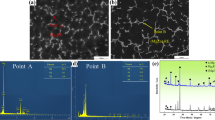

Tweaking the distribution of grains, precipitates, and texture components is a successful strategy employed to enhance the strength and formability of Mg alloys. Herein, moderate temperature equal channel angular pressing (ECAP) deformation was employed to control the microstructure and tune the corresponding mechanical properties of the Mg–6Zn–1Mn alloy. The analysis results indicated a uniform distribution of grains and second phases. The original strong basal texture of the extruded Mg–6Zn–1Mn alloy was disintegrated, and a weak basal texture gradually developed after 2 passes of ECAP deformation. The fine grains, second phases, and high-density dislocations provide high strength to the alloy, with contributions of 105.1 MPa, 47.1 MPa and 78.8 MPa, respectively. The excellent ductility (20.6%) is mainly attributed to the weak basal texture and high Schmid factor of prismatic <a> slip. The 2P sample exhibits good strength-ductility synergy effects with a value of YS × EL equal to 5.8. The results indicate that moderate temperature ECAP deformation can enable the formation of a uniform microstructure and unique texture to enhance the mechanical properties of the Mg–6Zn–1Mn alloy.

Graphic Abstract

Similar content being viewed by others

References

R.G. Li, H.R. Li, D.Y. Zhao, Y.Q. Dai, D.Q. Fang, J.H. Zhang, L. Zong, J. Sun, Mater. Sci. Eng. A 780, 139193 (2020)

H.C. Pan, D.S. Xie, J.R. Li, H.B. Xie, Q.Y. Huang, Q.S. Yang, G.W. Qin, Mater. Res. Lett. 9, 329 (2021)

H.C. Pan, R. Kang, J.R. Li, H.B. Xie, Z.R. Zeng, Q.Y. Huang, C.L. Yang, Y.P. Ren, G.W. Qin, Acta Mater. 186, 278 (2020)

H. Lv, L. Li, Z.Z. Wen, C.R. Liu, W. Zhou, X. Bai, H.L. Zhong, Mater. Sci. Eng. A 833, 142521 (2022)

Z. Yang, C. Xu, T. Nakata, S. Kamado, Mater. Sci. Eng. A 800, 140330 (2021)

X. Zhao, S.C. Li, Y.S. Zheng, Z.R. Liu, K. Chen, J.M. Yu, Z.M. Zhang, S.Q. Zheng, J. Alloys Compd. 883, 160871 (2021)

D.D. Zhang, C.M. Liu, S.N. Jiang, Y.H. Gao, Y.C. Wan, Z.Y. Chen, Mater. Sci. Eng. A 856, 143990 (2022)

Q. Xu, A.B. Ma, Y.H. Li, J.P. Sun, Y.C. Yuan, J.H. Jiang, C.Y. Ni, J. Magnes. Alloys 8, 192 (2020)

R.S. Pei, Y.C. Zou, M. Zubair, D.Q. Wei, T. Al-Samman, Acta Mater. 233, 117990 (2022)

M.T. Péerez-Prado, O.A. Ruano, Scr. Mater. 48, 59 (2003)

H. Yan, X.H. Shao, H.P. Li, R.S. Chen, H.Z. Cui, E.H. Han, Scr. Mater. 207, 114257 (2022)

Z.Q. Yang, A.B. Ma, B.Q. Xu, J.H. Jiang, H.R. Wu, J.P. Sun, Mater. Sci. Eng. A 841, 143023 (2022)

Y.C. Yuan, A.B. Ma, X.F. Gou, J.H. Jiang, G. Arhin, D. Song, H. Liu, Mater. Sci. Eng. A 677, 125 (2016)

L.B. Tong, J.H. Chu, W.T. Sun, Z.H. Jiang, D.N. Zou, S.F. Liu, S. Kamado, M.Y. Zheng, J. Magnes. Alloys 9, 1007 (2021)

J. Horky, K. Bryła, M. Krystian, G. Mozdzen, B. Mingler, L. Sajti, Mater. Sci. Eng. A 826, 142002 (2021)

H. Liu, H. Huang, Y. Zhang, Y. Xu, C. Wang, J.P. Sun, J.H. Jiang, A.B. Ma, F. Xu, J. Bai, J. Alloys Compd. 811, 151987 (2019)

K. Yan, J. Bai, H. Liu, Z.Y. Jin, J. Magnes. Alloys 5, 336 (2017)

M.A. Afifi, Y.C. Wang, P.H.R. Pereira, Y.W. Wang, S.K. Li, Y. Huang, T.G. Langdon, Mater. Sci. Eng. A 712, 146 (2018)

W.W. Lei, H. Zhang, Mater. Lett. 271, 127781 (2020)

X.W. Liu, L.P. Bian, F. Tian, S.J. Han, T. Wang, W. Liang, Mater. Charact. 188, 111910 (2022)

Y.T. Fu, J.P. Sun, Z.Q. Yang, B.Q. Xu, J. Han, Y.F. Chen, J.H. Jiang, A.B. Ma, Mater. Charact. 165, 110398 (2020)

K.B. Nie, Z.H. Zhu, K.K. Deng, J.G. Han, J. Magnes. Alloys 8, 676 (2020)

D.L. Yu, D.F. Zhang, J. Sun, Y.X. Luo, J.Y. Xu, H.J. Zhang, F.S. Pan, Mater. Sci. Eng. A 662, 1 (2016)

D.L. Yu, D.F. Zhang, Q.W. Dai, W. Lan, J. Peng, J.Y. Xu, F.G. Qi, F.S. Pan, Mater. Sci. Eng. A 711, 624 (2018)

J. Peng, X.S. Tong, S.L. Shang, F.S. Pan, Rare Metal Mater. Eng. 42, 1627 (2013)

C.Q. Liu, X.H. Chen, J. Chen, A. Atrens, F.S. Pan, J. Magnes. Alloys 9, 1081 (2021)

H.F. Zhang, Y.T. Ding, L. Jian, Y. Shen, J.J. Chen, Y.B. Gao, Mater. Rep. 36, 172 (2022)

W. Yang, G.F. Quan, B. Ji, Y.F. Wan, H. Zhou, J. Zheng, D.D. Yin, J. Magnes. Alloys 10, 195 (2022)

Z.H. Shan, J. Yang, J.F. Fan, H. Zhang, Q. Zhang, Y.C. Wu, W.G. Li, H.D. Dong, B.S. Xu, J. Magnes. Alloys 9, 548 (2021)

Z.Z. Gui, F. Wang, J.Y. Zhang, D.X. Chen, Z.X. Kang, J. Magnes. Alloys 10, 239 (2022)

X. Zhao, S.C. Li, Z.M. Zhang, P.C. Gao, S.L. Kan, F.F. Yan, J. Magnes. Alloys 8, 624 (2020)

K.K. Guo, M.Y. Liu, J.F. Wang, Y.F. Sun, W.Q. Li, S.J. Zhu, L.G. Wang, S.K. Guan, J. Magnes. Alloys 8, 873 (2020)

Y.W. Gui, L.X. Ouyang, Y.J. Cui, H.K. Bian, Q.A. Li, A. Chiba, J. Magnes. Alloys 9, 456 (2021)

H.F. Zhang, Y.T. Ding, R.M. Li, Y. Shen, J. Lei, Mater. Sci. Eng. A 853, 143733 (2022)

W.J. Kima, S.I. Hong, Y.S. Kim, S.H. Min, H.T. Jeong, J.D. Lee, Acta Mater. 51, 3293 (2003)

Z.H. Chen, Wrought Magnesium Alloy, 1nd edn. (Chemical Industry Press, 2005), pp. 335–336.

B.Q. Xu, J.P. Sun, Z.Q. Yang, L.R. Xiao, H. Zhou, J. Jin, H. Liu, Y.N. Wu, Y.C. Yuan, X.R. Zhou, D. Song, J.H. Jiang, A.B. Ma, Mater. Sci. Eng. A 780, 139191 (2020)

K. Bryła, Mater. Sci. Eng. A 772, 138750 (2020)

X.P. Zhang, S. Castagne, C.F. Gu, X.F. Luo, J. Mater. Sci. 46, 1124 (2011)

H.H. Yu, Y.C. Xin, M.Y. Wang, Q. Liu, J. Mater. Sci. Technol. 34, 248 (2018)

L. Li, C.C. Zhang, H. Lv, C.R. Liu, Z.Z. Wen, J.W. Jiang, J. Magnes. Alloys 10, 249 (2022)

Acknowledgements

The authors gratefully acknowledge the financial supports from the Hongliu first-class discipline construction plan of Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Lei, J., Ding, Y. et al. Evading Strength-Ductility Tradeoff in Mg Alloy via Uniform Microstructure and Unique Texture Modification Induced by Moderate Temperature ECAP. Met. Mater. Int. 29, 1863–1879 (2023). https://doi.org/10.1007/s12540-022-01350-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01350-1