Abstract

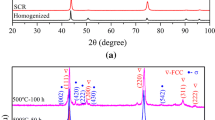

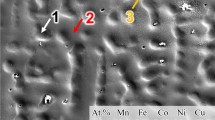

Microstructure and mechanical behavior of a non-equiatomic Cr30Fe30Ni15Co10Cu10Ti5 high-entropy alloy were investigated during cold rolling. The alloy was cast by vacuum arc melting and after homogenization, it was hot rolled and solution annealed. The as-cast microstructure consisted of two face-centered cubic (FCC1: Ni-rich, FCC2: Cu-rich) and a hard Cr-rich σ phases. The dendritic structure disappeared after solution annealing and the σ phase partially transformed to a softer phase with a body-centered cubic (BCC) structure. The addressed thermomechanical process was found to result in favorable microstructural characteristics, which provided the possibility of subsequent heavy cold rolling up to 85% thickness reduction. Results indicated that while no phase transformation was detected during the cold rolling, the plastic deformation followed the dislocation slip mechanism at the early stages. The formation of mechanical twinning and shear bands were also identified as the main plastic deformation mechanisms at the higher levels of cold rolling in FCC1. In addition, grain refinement by dynamic recrystallization mechanism was observed in the BCC phase. However, the grain size of the Cu-rich phase was refined to < 500 nm after just a 25% thickness reduction. Although a small number of interfacial and intergranular cracks were initiated in some of the σ phase particles, a good material flow was observed around this hard phase. The results also showed that applying 85% cold rolling lead to a significant increase in ultimate tensile strength (UTS) of the material to 1794 MPa. However, the optimum combination of UTS and elongation (1267 MPa and 31%, respectively) was achieved after thickness reduction of 40%.

Graphical abstract

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang. Adv. Eng. Mater. 6, 299 (2004)

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375-377, 213 (2004)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014)

G. Sheng, C.T. Liu, Prog. Nat. Sci. Mater. Int. 21, 433 (2011)

L. Kaushik, M.-S. Kim, J. Singh, J.-H. Kang, Y.-U. Heo, J.-Y. Suh, S.-H. Choi, Int. J. Plasticity 141, 102989 (2021)

L.J. Zhang, J.T. Fan, D.J. Liu, M.D. Zhang, P.F. Yu, Q. Jing, M.Z. Ma, P.K. Liaw, G. Li, R.P. Liu, J. Alloy. Compd. 745, 75 (2018)

J.W. Qiao, S.G. Ma, E.W. Huang, C.P. Chuang, P.K. Liaw, Y. Zhang, Mater. Sci. Forum 688, 419 (2011)

Y.K. Kim, B.J. Lee, S.-K. Hong, S.I. Hong, Mater. Sci. Eng. A 781, 139241 (2020)

Q. Li, T.W. Zhang, J.W. Qiao, S.G. Ma, D. Zhao, P. Lu, Z.H. Wang, J. Alloy. Compd. 816, 152663 (2020)

J. Hou, M. Zhang, S. Ma, P.K. Liaw, Y. Zhang, J. Qiao, Mater. Sci. Eng. A 707, 593 (2017)

A. Shabani, M.R. Toroghinejad, A. Shafyei, P. Cavaliere, Materialia 1, 175 (2018)

I.S. Wani, G. Dan Sathiaraj, M.Z. Ahmed, S.R. Reddy, P.P. Bhattacharjee, Mater. Charact. 118, 417 (2016)

E.P. George, W.A. Curtin, C.C. Tasan, Acta Mater. 188, 435 (2020)

A. Radi, P. Asghari-Rad, H.S. Kim, G.G. Yapici, J. Alloy. Compd. 905, 164014 (2022)

D. Liu, X. Jin, N. Guo, P.K. Liaw, J.W. Qiao, Mater. Sci. Eng. A 818, 141386 (2021)

X. Jun, C. Cao, G. Ping, L. Peng, T. Nonferr. Metal. Soc. 30, 746 (2020)

B. Tripathy, S.R.K. Malladi, P.P. Bhattacharjee, Mater. Sci. Eng. A 831, 142190 (2022)

H. Yang, Y. Tan, J. Qiao, J.A. Hawk, Y. Zhang, M. Gao, P.K. Liaw Metals 12, 178 (2022)

X.F. Wang, Y. Zhang, Y. Qiao, G.L. Chen, Intermetallics 15, 357 (2007)

B.S. Li, Y.P. Wang, M.X. Ren, C. Yang, H.Z. Fu, Mater. Sci. Eng. A 498, 482 (2008)

A. Rezaee, M. Ketabchi, S.A.A. Shams, H.R. Jafarian, Mater. Sci. Technol. (2022). https://doi.org/10.1080/02670836.2022.2080327

N. Derimow, R. Abbaschian, Mater. Today Commun. 15, 1 (2018)

H. Shahmir, M. Nili-Ahmadabadi, A. Shafiee, T.G. Langdon, Mater. Sci. Eng. A 718, 468 (2018)

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, J. Shi, Mater. Sci. Eng. A 508, 214 (2009)

H. Watanabe, T. Murata, S. Nakamura, N. Ikeo, T. Mukai, K. Tsuchiya, J. Alloy. Compd. 872, 159668 (2021)

R.E. Reed-Hill, Physical Metallurgy Principles (Van Nostrand, New York, 1973)

Z. Lv, P. Jiang, Z. Wang, W. Zhang, S. Sun, W. Fu, Mater. Lett. 62, 2825 (2008)

T. Shintani, Y. Murata, Acta Mater. 59, 4314 (2011)

K. Biswas, N. Gurao, Mater. Sci. Eng. A 657, 224 (2016)

A.S. Tirunilai, J. Sas, K.-P. Weiss, H. Chen, D.V. Szabó, S. Schlabach, S. Haas, D. Geissler, J. Freudenberger, M. Heilmaier, A. Kauffmann, J. Mater. Res. 33, 3287 (2018)

S.A.A. Shams, G. Jang, J.W. Won, J.W. Bae, H. Jin, H.S. Kim, C.S. Lee, Mater. Sci. Eng. A 792, 139661 (2020)

F. Berrenberg, C. Haase, L.A. Barrales-Mora, D.A. Molodov, Mater. Sci. Eng. A 681, 56 (2017)

S. Martin, S. Wolf, U. Martin, L. Krüger, D. Rafaja, Metall. Mater. Trans. A 47, 49 (2016)

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, D. Barbier, Curr. Opin. Solid State Mater. Sci. 15, 141 (2011)

P. Kusakin, R. Kaibyshev, High-Mn twinning-induced plasticity steels: microstructure and mechanical properties. Rev. Adv. Mater. Sci. 44, 326 (2016)

J. Liu, C. Chen, Y. Xu, S. Wu, G. Wang, H. Wang, Y. Fang, L. Meng, Scripta Mater. 137, 9 (2017)

W. Guo, J. Li, M. Qi, Y. Xu, H.R. Ezatpour, J. Alloy. Compd. 905, 163791 (2022)

R.E. Schramm, R.P. Reed, Metall. Trans. A 6, 1345 (1975)

C.W. Shao, P. Zhang, Y.K. Zhu, Z.J. Zhang, J.C. Pang, Z.F. Zhang, Acta Mater. 134, 128 (2017)

Y. Wang, J. Jin, M. Zhang, F. Liu, X. Wang, P. Gong, X. Tang, J. Alloy. Compd. 891, 161822 (2022)

O. Muransky, L. Balogh, M. Tran, C.J. Hamelin, J.-S. Park, M.R. Daymond, Acta Mater. 175, 297 (2019)

X. Zhang, P. Wang, D. Li, Y. Li, J. Mater. Sci. Technol. 72, 180 (2021)

G.E. Dieter, D. Bacon, Mechanical Metallurgy (McGraw-hill, New York, 1976)

M Geetha, A.K Singh, K Muraleedharan, A.K Gogia, R Asokamani, J. Alloy. Compd. 329, 264 (2001)

C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Metall. Mater. Trans. A 36, 881 (2005)

S. W. Wu, G. Wang, J. Yi, Y. D. Jia, I. Hussain, Q. J. Zhai, P. K. Liaw, Mater. Res. Lett. 5, 276 (2017)

B.C. De Cooman, Y. Estrin, S.K. Kim, Acta Mater. 142, 283 (2018)

K. Jeong, J.-E. Jin, Y.-S. Jung, S. Kang, Y.-K. Lee, Acta Mater. 61, 3399 (2013)

J.-K. Kim, J.H. Kim, H. Park, J.-S. Kim, G. Yang, R. Kim, T. Song, D.-W. Suh, J. Kim, Int. J. Plasticity 148, 103148 (2022)

S.A.A. Shams, G. Kim, J.W. Won, J.N. Kim, H.S. Kim, C.S. Lee, Mater. Sci. Eng. A 810, 140985 (2021)

H. Shahmir, J. He, Z. Lu, M. Kawasaki, T.G. Langdon, Mater. Sci. Eng. A 676, 294 (2016)

Z. Li, L. Fu, J. Peng, H. Zheng, A. Shan, Mater. Sci. Eng. A 786, 139446 (2020)

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, E.P. George, Acta Mater. 61, 5743 (2013)

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, G. Salishchev, Intermetallics 59, 8 (2015)

Z. Li, C.C. Tasan, K.G. Pradeep, D. Raabe, Acta Mater. 131, 323 (2017)

Acknowledgements

This study was financially supported by the Grant-in-Aid through Iran National Science Foundation (INSF), Iran (contact No. 98010859), and the supports is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rezaee, A., Ketabchi, M., Shams, S.A.A. et al. Characteristics of the Cold-Rolled Multi-Phase Cr30Fe30Ni15Co10Cu10Ti5 High-Entropy Alloy. Met. Mater. Int. 29, 1366–1381 (2023). https://doi.org/10.1007/s12540-022-01296-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01296-4