Abstract

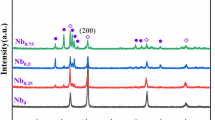

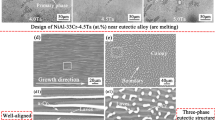

Three ternary Laves phase-based eutectic alloys CrFeNbx (x = 2.0, 2.35, 2.7) were designed successfully by combining the binary phase diagrams and thermodynamics calculations. With the increasing Nb content, the solidified microstructures evolved from the primary (Cr, Fe)2Nb plus the eutectic (Cr, Fe)2Nb/Nbss in the CrFeNb2.0, via the full eutectic (Cr, Fe)2Nb/Nbss in the CrFeNb2.35, and finally to the primary Nbss plus the eutectic (Cr, Fe)2Nb/Nbss in the CrFeNb2.7. The full eutectic (Cr, Fe)2Nb/Nbss of the CrFeNb2.35 was found with outstanding thermal stability, and the lamellar eutectic was quite stable even under the heat-treatment of 1273 K/48 h. The compression strength and fracture toughness increased firstly and decreased subsequently with the increase of Nb content, which reached their maximums of 2.54 GPa and 18.25 MPa·m1/2, respectively, in the CrFeNb2.35. The excellent combination of compression strength and fracture toughness in the CrFeNbx (x = 2.0, 2.35, 2.7) were attributed to the synergistic effects of Laves phase strengthening, interface strengthening, solid solution strengthening, alloying toughening and Nbss phase toughening mechanisms.

Graphical Abstract

Similar content being viewed by others

References

H.T. Huang, G.F. Li, X. Xiao, S.Q. Lu, P. Peng, J. Alloys Compd. 857, 158040 (2021)

M.F. Chisholm, Science 307, 701–703 (2005)

J. Guénolé, F.-Z. Mouhib, L. Huber, B. Grabowski, S. Korte-Kerzel, Scr. Mater. 166, 134 (2019)

Y.L. Xue, S.M. Li, Y.T. Wu, H.L. Liu, K.W. Li, J. Alloys. Compd. 825, 153957 (2020)

H. Jiang, K.M. Han, X.X. Gao, Y.P. Lu, Z.Q. Cao, M.C. Gao, J.A. Hawk, T.J. Li, Mater. Des. 142, 101 (2018)

K.S. Chan, D.L. Davidson, Mater. Trans. A 34, 1833 (2003)

Y.L. Xue, S.M. Li, H. Zhong, H.Z. Fu, Mater. Sci. Eng. A 638, 340 (2015)

W.F. Brown, J.E. Srawley, Annual Book of Standards (American Society for Testing and Materials, Pennsylvania, 1993)

C.J. Cui, Y. Wang, K. Zhang, C.Y. Wu, W. Liu, L. Deng, C. Wang, H.J. Su, Mater. Sci. Eng. A 824, 141765 (2021)

S.S. Mishra, T.P. Yadav, O.N. Srivastava, N.K. Mukhopadhyay, K. Biswas 2020, J. Alloys Compd. 153764

D. Chung, Z.Y. Ding, Y. Yang, Adv. Eng. Mater. 21, 1801060 (2019)

H. Choe, J.H. Schneibel, R.O. Ritchie, Metall. Mater. Trans. A 34, 225 (2003)

Y.L. Xue, S.M. Li, Y.T Wu, C.Q.Liu, H.L. Liu, L. Yuan 2020, Vacuum 174, 109202.

S. Voss, M. Palm, F. Stein, D. Raabe, J. Phase Equilibria Diffus. 32, 97 (2011)

Q.X. Long, J.C. Wang, Y. Du, X.W. Nie, Z.P. Jin, J. Min. Metall. Sect. B 53, 13 (2017)

G.R. Anstis, P. Chantikul, B.R. Lawn, D.B. Marshall, J. Am. Ceram. Soc. 64, 533 (1981)

J.H. Zhu, C.T. Liu, P.K. Liaw, Intermetallics 7, 1011 (1999)

C. Schmetterer, A. Khvan, A. Jacob, B. Hallsted, T. Markus, J. Phase Equilibria Diffus. 35, 434. (2014)

L. Wang, C.L. Yao, J. Shen, Y.P. Zhang, T. Wang, Y.H. Ge, L.H. Gao, G.J. Zhang, Intermetallics 118, 1066881 (2020)

B.P. Bewlay, H.A. Lipsitt, M.R. Jackson, W.J. Reeder, J.A. Sutliff, Mater. Sci. Eng. A 192–193, 534 (1995)

K.S. Chan, D.L. Davidson, Metall. Mater. Trans. A 32, 2717 (2001)

S.Q. Lu, H.Z. Zheng, L.P. Deng, J. Yao, Mater. Des. 51, 432 (2013)

D.L. Davidson, K.S. Chan, Scr. Mater. 38, 1155 (1998)

D.L. Davidson, K.S. Chan, D.L. Anton, Metall. Mater. Trans. A 27, 3007 (1996)

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102, 187 (2016)

S.I. Rao, C. Woodward, B. Akdim, O.N. Senkov, D. Miracle, Acta Mater. 209, 116758. (2021)

D. Wu, J.Y. Zhang, J.C. Huang, H. Bei, T.G. Nieh, Scr. Mater. 68, 118. (2013)

L. Jiang, H. Jiang, Y.P. Lu, T.M. Wang, Z.Q. Cao, T.J. Li, J. Mater. Sci. Technol. 31, 397 (2015)

G.Y. Lin, K.S. Chan, Metall. Mater. Trans. A 30, 3239 (1999)

C.D. Rabadia, Y.J. Liu, S.F. Jawed, L. Wang, Y.H. Li, X.H. Zhang, T.B. Sercombe, H. Sun, L.C. Zhang, Mater. Des. 160, 1059 (2018)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51701110); the Natural Science Foundation of Shaanxi Province (No. 2022GY-394); the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201728); and the Shaanxi Key Laboratory of Green Preparation and Functionalization for Inorganic Materials (No. 202005).

Author information

Authors and Affiliations

Contributions

YX: Conceptualization, Methodology, Writing-review & editing. YW: Data curation, Writing-original draft. HS and NF: Visualization, Investigation. LY: Software, Validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xue, Y., Wang, Y., Sun, H. et al. Designing Ternary Laves Phase-Based Eutectic Alloys CrFeNbx with Excellent Strength, Toughness, and Thermal Stability. Met. Mater. Int. 29, 564–574 (2023). https://doi.org/10.1007/s12540-022-01231-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01231-7