Abstract

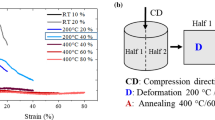

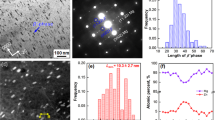

The influence of changes in temperature from 250 to 400 °C with 50 °C intervals during ECAP processing on the texture evolution and recrystallization behavior for Mg–9Al–1Zn alloy was studied. The results demonstrate that {10 \({\overline{\text{1}}}\) 2} extension twins and dislocation slip are the dominating deformation modes in low temperature (250 °C and 300 °C) ECAP processing, and those twins gradually disappear with increasing temperature. Most of the recrystallized grains are observed to exhibit (0001) poles 70°–90° away from the normal direction due to reorientation of the grains caused by twins and dislocation slips, with the texture changing from a strong basal texture to the texture component close to {\({\overline{\text{1}}}\) 2 \({\overline{\text{1}}}\) 0} and {01 \({\overline{\text{1}}}\) 0}. The production of ultrafine recrystallized grains in the specimens treated by ECAP at 400 °C was aided by grain fragmentation caused by twins interaction, as well as dislocation slip and temperature increase during severe plastic deformation (SPD).

Graphical abstract

Similar content being viewed by others

References

M. Zhang, L. Liu, S. Liang, J. Li, Met. Mater. Int. 26, 1585 (2020)

K.D. Molodov, T. Al-Samman, D.A. Molodov, G. Gottstein, Acta Mater. 103, 711 (2016)

L. Song, B. Wu, X. Du, Y. Wang, C. Esling, M.-J. Philippe, Mater. Sci. Eng. A 778, 138921 (2020)

F. Shen, Z. Sun, W. Li, Z. Zhou, S. Zhong, H. Huang, J. Guo, C. Xie, Y. Wang, D. Yi, J. Alloy. Compd. 816, 152415 (2020)

M.M. Hoseini-Athar, R. Mahmudi, R.P. Babu, P. Hedström, Mater. Sci. Eng. A 772, 138833 (2020)

D. Guan, B. Wynne, J. Gao, Y. Huang, W.M. Rainforth, Acta Mater. 170, 1 (2019)

Y.B. Chun, C.H.J. Davies, Mater. Sci. Eng. A 528, 3489 (2011)

S.W. Xu, N. Matsumoto, S. Kamado, T. Honma, Y. Kojima, Mater. Sci. Eng. A 517, 354 (2009)

L. Wang, Y. Li, H. Zhang, Z. Zhang, Q. Yang, Q. Zhang, H. Wang, W. Cheng, K.S. Shin, M. Vedani, J. Mater. Res. Technol. 9, 12604 (2020)

Y. Ma, F.-Y. Han, C. Liu, M.-Z. Li, Acta Metall. Sin. 33, 233 (2019)

H. Yu, Y. Xin, M. Wang, Q. Liu, J. Mater. Sci. Technol. 34, 248 (2018)

J.H. Lee, S.H. Park, S.-G. Hong, J.W. Won, C.S. Lee, Scripta Mater. 99, 21 (2015)

H. Su, X. Zhou, S. Zheng, H. Ye, Z. Yang, J. Mater. Sci. Technol. 66, 28 (2021)

Z.-Z. Shi, X.-F. Liu, J. Alloy. Compd. 692, 274 (2017)

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Prog. Mater. Sci. 60, 130 (2014)

E. Mostaed, A. Fabrizi, D. Dellasega, F. Bonollo, M. Vedani, Mater. Charact. 107, 70 (2015)

S.H. Park, S.-G. Hong, J.H. Lee, Y.-H. Huh, J. Alloy. Compd. 646, 573 (2015)

H. Chen, B. Song, N. Guo, T. Liu, T. Zhou, J. He, Met. Mater. Int. 25, 147 (2019)

G.-S. Song, S.-H. Zhang, L. Zheng, L. Ruan, J. Alloy. Compd. 509, 6481 (2011)

I.J. Beyerlein, X. Zhang, A. Misra, Annu. Rev. Mater. Res. 44, 329 (2014)

H. Hu, Z. Sun, Z. Ou, X. Wang, Met. Mater. Int. 23, 582 (2017)

Y. Cubides, D. Zhao, L. Nash, D. Yadav, K. Xie, I. Karaman, H. Castaneda, J. Magnes. Alloy. 8, 1016 (2020)

S.Q. Zhu, S.P. Ringer, Acta Mater. 144, 365 (2018)

B. Wang, L. Deng, N. Guo, Z. Xu, Q. Li, Mater. Charact. 98, 180 (2014)

J.J. Jonas, S. Mu, T. Al-Samman, G. Gottstein, L. Jiang, Ė Martin, Acta Mater. 59, 2046 (2011)

A. Khosravani, D.T. Fullwood, B.L. Adams, T.M. Rampton, M.P. Miles, R.K. Mishra, Acta Mater. 100, 202 (2015)

Y. Li, P. Hou, Z. Wu, Z. Feng, Y. Ren, H. Choo, Mater. Design 202, 109562 (2021)

H. Nie, X. Hao, H. Chen, X. Kang, T. Wang, Y. Mi, W. Liang, Mater. Design 181, 107948 (2019)

B. Zhu, X. Liu, C. Xie, Y. Wu, J. Zhang, Vacuum 160, 279 (2019)

L. Zhang, C.-G. Liu, H.-Y. Wang, X.-L. Nan, G.-J. Liu, Q.-C. Jiang, Mater. Sci. Eng. A 597, 376 (2014)

D. Guan, W.M. Rainforth, L. Ma, B. Wynne, J. Gao, Acta Mater. 126, 132 (2017)

D. Guan, W.M. Rainforth, J. Gao, J. Sharp, B. Wynne, L. Ma, Acta Mater. 135, 14 (2017)

J.J. Bhattacharyya, S.R. Agnew, G. Muralidharan, Acta Mater. 86, 80 (2015)

L.B. Tong, M.Y. Zheng, H. Chang, X.S. Hu, K. Wu, S.W. Xu, S. Kamado, Y. Kojima, Mater. Sci. Eng. A 523, 289 (2009)

X. Wang, P. Mao, R. Wang, Z. Liu, Z. Wang, F. Wang, L. Zhou, Z. Wei, Mater. Sci. Eng. A 772, 138814 (2020)

C. Lou, X. Zhang, Y. Ren, Mater. Charact. 107, 249 (2015)

S.-G. Hong, S.H. Park, C.S. Lee, Acta Mater. 58, 5873 (2010)

L. Zhao, Y. Xin, Y. Wu, Q. Liu, Mater. Sci. Eng. A 717, 34 (2018)

B.J. Kwak, S.H. Park, Y.H. Moon, J.H. Lee, T. Lee, Mater. Sci. Eng. A 788, 139496 (2020)

H. Esmaeilpour, A. Zarei-Hanzaki, N. Eftekhari, H. R. Abedi, M.R. Ghandehari Ferdowsi, Mater. Sci. Eng. A 778, 139021 (2020)

F. Mokdad, D.L. Chen, D.Y. Li, Mater. Design 119, 376 (2017)

G. Liu, R. Xin, F. Liu, Q. Liu, Mater. Design 107, 503 (2016)

X. Li, J. Zhang, D. Hou, Q. Li, Mater. Sci. Eng. A 729, 466 (2018)

L.B. Tong, J.H. Chu, Z.H. Jiang, S. Kamado, M.Y. Zheng, J. Alloy. Compd. 785, 410 (2019)

H. Huang, H. Liu, C. Wang, J. Sun, J. Bai, F. Xue, J. Jiang, A. Ma, J. Magnes. Alloy. 7, 617 (2019)

Acknowledgements

The authors would like to express their sincere thanks for the research grants supported by the National Natural Science Foundation of China (Grant No.51805002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Sun, R., Li, G. et al. Dynamic Recrystallization Behaviors and the Texture Evolution in Mg–9Al–1Zn Alloy Produced by ECAP at Different Temperatures. Met. Mater. Int. 28, 2677–2690 (2022). https://doi.org/10.1007/s12540-021-01158-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01158-5