Abstract

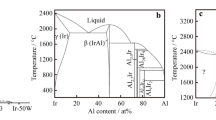

The β-NiAl phase, which may exacerbate the high-temperature mechanical properties of Ni-based superalloy, was observed in a designed Re-containing single crystal superalloy. The solidification mechanism of β-NiAl phase and its evolution after solution treatment as well as long-term aging at 1120 °C were systematically investigated. The β-NiAl phase was confirmed by the analyses of XRD and TEM in as-cast specimen. Combined the analyses of TEM, DSC, phase diagrams and chemical segregation behaviors obtained via EPMA, the solidification path in interdendritic region was determined as L → (β-NiAl + Cr) eutectic, L → β + δ, L + β → γ′, L → γ′. The β-NiAl phase could be diminished by solution treatment and/or long-term aging treatment. After the solution treatment at 1330 °C for 30 min, the β-NiAl phase split into small bulks and the δ phase dissolved, contributing to the formation of the γ + γ′ structure and large blocky δ phase. During the long-term aging at the 1120 °C, the β-NiAl phase transformed into γ and γ′ phase. With aging time prolonging, the Cr-rich phase dissolved, which promoted the precipitation of TCP confirmed as μ phase with three morphologies.

Graphical Abstract

After solution treatment at high temperature for 30 min, β-NiAl phase dissolved and reprecipitated into small bunks surrounded with filmier γ′phase, and γ + γ′microstructures as well as large δ phase were formed via the chemical diffusion and redistribution at high temperature. After long-term aging at 1120 °C, β-NiAl phase gradually dissolved and transformed to γ′phase and γ phase. Moreover, the precipitation of TCP phase was accelerated with aging time prolonging.

Similar content being viewed by others

References

R.C. Reed, The Superalloys: Fundamentals and Application, 1st ed. (Cambridge University Press, Cambridge, 2008)

Z.H. Tan, X.G. Wang, Y.L. Du, Y.M. Li, Y.H. Yang, J.L. Liu, J.D. Liu, J.G. Li, Y.Z. Zhou, X.F. Sun, Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-021-01040-4

M. Zietara, S. Neumeier, M. Gken, A. Czyrska-Filemonowicz, Met. Mater. Int. 23, 126 (2017)

Y.L. Du, Z.H. Tan, Y.H. Yang, X.G. Wang, Y.Z. Zhou, J.G. Li, X.F. Sun, Met. Mater. Int. 27, 5173 (2021)

W. Yang, P. Qu, R. Zhang, J. Qin, L. Liu, Met. Mater. Int. 27, 1892 (2021)

J.R. Li, Z.G. Zhong, D.Z. Tang, S.Z. Liu, P. Wei, P.Y. Wei, Z.T. Wu, D. Huang, M. Han, in Superalloys 2000, ed. by T.M. Pollock, R.D. Kissinger, R.R. Bowman, K.A. Green, M. McLean, S. Olson, J.J. Schina (TMS, Pittsburgh, 2000), pp. 777-783

Y.N. Shmotin, A.V. Logunov, I.A. Leshchenko, D.V. Danilov, Rus. Metall. 2016, 1214 (2016)

C.M.F. Rac, R.C. Reed, Acta Mater. 49, 4113 (2001)

K. Cao, W. Yang, J. Zhang, P. Qu, C. Liu, H. Su, J. Zhang, L. Liu, J. Alloy. Compd. 870, 159419 (2021)

Q. Feng, T.K. Nandy, S. Tin, T.MPollock, Acta Mater. 51, 269 (2003)

Q. Feng, L.J. Carroll, T.M. Pollock, Metall. Mater. Trans. A 37, 1949 (2006)

K. Matuszewski, R. Rettig, H. Matysiak, Z. Peng, I. Povstugar, P. Choi, J. Müller, D. Raabe, E. Spiecker, K.J. Kurzydłowski, R.F. Singer, Acta Mater. 95, 274 (2015)

R.D. Noebe, R.R. Broman, M.V. Nathal, Int. Mater. Rev. 38, 193 (1993)

R.D. Noebe, R.R. Bowman, M.V. Nathal, Review of the physical and mechanical properties and potential applications of the B2 compound NiAl ( Unabridged version of a paper published in International materials review). NASA Technical Memorandum, AD-A274-700 (1992)

X.P. Tan, Y.J. Tan, J.L. Liu, T. Jin, Met. Mater. Int. 21, 222 (2015)

T.Z. Xin, S. Tang, F. Ji, L.K. Ning, Z. Zheng, J. Alloy. Compd. 641, 228 (2015)

W. Song, X.G. Wang, J.G. Li, J. Meng, T.F. Duan, Y.H. Yang, J.L. Liu, J.D. Liu, W.L. Pei, Y.Z. Zhou, X.F. Sun, J. Alloy. Compd. 848, 156584 (2020)

H. Wang, H. Su, J. Zhang, Guomin, Y. Zhang, Q. Yue, L. Liu, T. Huang, W. Yang, H. Fu, Mater. Charact. 130, 211 (2017)

Y.J. Zhang, Y.J. Huang, L. Yang, J.G. Li, J. Alloy. Compd. 570, 70 (2013)

P. Wollgramm, H. Buck, K. Neuking, A.B. Parsa, S. Schuwalow, J. Rogal, R. Drautz, G. Eggeler, Mater. Sci. Eng. A 628, 382 (2015)

M. Huang, Z. Cheng, J. Xiong, J. Li, J. Hu, Z. Liu, J. Zhu, Acta Mater. 76, 294 (2014)

A.F. Giamei, D.L. Anton, Metall. Trans. A 16, 1997 (1985)

C. Frey, R. Sliverstein, T.M. Pollock, Acta Materialia. 229 117767 (2022). https://doi.org/10.1016/j.actamat.2022.117767

D.R. Johnson, X.F. Chen, B.F. Oliver, R.D. Noebe, J.D. Whittenberger, Intermetallics 3, 99 (1995)

F. Wang, D. Ma, J. Zhang, S. Bogner, A. Bührig-Polaczek, Mater. Charact. 101, 20 (2015)

M. Terner, H.Y. Yoon, H.U. Hong, S.M. Seo, J.H. Gu, J.H. Lee, Mater. Charact. 105, 56 (2015)

H. Chen, G.A. Jackson, K.T. Voisey, D.G. McCartney, Surf. Coat. Tech. 291, 34 (2016)

K.Y. Chen, C.Y. Jo, T. Jin, Z.Q. Hua J. Alloy. Compd. 509, 7078 (2011)

X. Zhou, X. Jie, Y.L. Pei, S.S. Li, S.K. Gong, Mater. Sci. Forum 849, 482 (2016)

L.K. Ning, J. Tong, E.Z. Liu, Z. Tang, H.S. Ji, Z. Zheng, Acta Metall. Sin. 53, 423 (2017)

I. Ansara, B. Sundman, P. Willemin, Acta Metall. 36, 977 (1988)

L.A. Cornish, M.J. Witcomb, J. Alloy. Compd. 291, 145 (1999)

G. Liu, L. Liu, X.B. Zhao, T.W. Huang, J. Zhang, Adv. Mater. Res. 278, 423 (2011)

Q. Feng, T.K. Nandy, L.J. Rowland, B. Tryon, D. Banerjee, T.M. Pollock, in Superalloys 2004, ed. by K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, S, Walston (TMS, Pittsburgh, 2004), pp. 769-778

P. Gargano, H. Mosca, G. Bozzolo, R.D. Noebe, Scripta Mater. 48, 695 (2003)

C.C. Jia, K. Ishida, T. Nishizawa, Rare Metal. Mat. Eng. 30, 173 (2001)

Y.S. Guan, E.Z. liu, X.R. Guan, Z. Zheng, J. Mater. Sci. Technol. 32, 271 (2016)

R.M. Kearsey, J.C. Beddoes, P. Jones, P. Au, Intermetallics 12, 903 (2004)

S.-M. Seo, H.-W. Jeong, Y.-K. Ahn, D.W. Yun, J.-H. Lee, Y.-S. Yoo, Mater. Charact. 89, 43 (2014)

J.Y. Chen, Q. Feng, Z.Q. Sun, Scripta Mater. 63, 795 (2010)

R. Retting, A. Heckl, R.F. Singer, Adv. Mater Res. 278, 180 (2011)

Z.H. Tan, L. Yang, X.G. Wang, Y.L. Du, L.H. Ye, G.C. Hou, Y.H. Yang, J.L. Liu, J.D. Liu, J.G. Li, Y.Z. Zhou, X.F. Sun, Acta Metall. Sin. (Engl. Lett.) 33, 731 (2020)

X.P. Tan, J.L. Liu, T. Jin, Z.Q. Hu, H.U. Hong, B.G. Choi, I.S. Kim, Y.S. Yoo, C.Y. Jo Metall. Mater. Trans. A 43, 3608 (2012)

Acknowledgements

The financial supports provided by National Key R&D Program of China under Grant No. 2017YFA0700704, National Science and Technology Major Project under Grant No. 2017-VI-0002-0072, National Natural Science Foundation of China (NSFC) under Grant No. 51671188 and Youth Innovation Promotion Association, Chinese Academy of Sciences Innovation Academy for Light-duty Gas Turbine, Chinese Academy of Sciences under Grant No. CXYJJ20-MS-03, for carrying out this work are gratefully acknowledged. Thanks for the help of Z.C. Zhu (Institute of Metal Research) with the experiments and writing.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y.M., Wang, X.G., Tan, Z.H. et al. Solidification and Evolution of β-NiAl Phase in a Re-Containing Single Crystal Superalloy. Met. Mater. Int. 28, 2305–2317 (2022). https://doi.org/10.1007/s12540-021-01136-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01136-x