Abstract

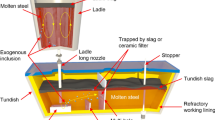

In continuous casting, the molten metal quality in the mold is affected by flow pattern, temperature distribution and inclusion transport in the multistrand tundish. Natural convection due to thermal buoyancy directly influences these parameters and with gas bubbling, further improvisation can be made. In the present work, numerical investigation of the effect of thermal buoyancy is carried out to examine the flow field, temperature distribution and inclusion trajectories. Further, gas bubbling curtain modeling using the Euler-Euler approach is performed for the different locations on the bottom wall of the tundish and quantitative analysis of tundish performance is presented using residence time distribution (RTD) curves. The results show that big circulation loop generated due to thermal buoyancy assists in inclusion removal and mixing at each outlet. Gas bubbling increases the molten metal flow velocity in the central region of tundish, leading to a decrease in the dimensionless number Gr/Re2 near the outlets which are far away from the inlet of the tundish i.e. outlet 2 and outlet 3. Hence, the dominance of natural convection decreases. The inclusion removal rate is found to increase significantly as the circulation loop formed at each side of the curtain forces them upward direction. However, the reported inclusion removal rate in gas bubbling cases is found to be independent of particle size and curtain location.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- g:

-

Gravitational acceleration

- t:

-

Time

- k :

-

Turbulent kinetic energy

- ε :

-

Rate of dissipation of turbulent kinetic energy

- p :

-

Pressure

- \(F_{D}\) :

-

Drag force

- \(C_{D}\) :

-

Drag coefficient

- T :

-

Temperature

- d :

-

Diameter

- R :

-

Nozzle radius

- u :

-

Flow velocity

- K :

-

Interphase momentum exchange coefficient

- h :

-

Enthalpy

- τ :

-

Relaxation time

- µ :

-

Viscosity

- i :

-

Direction coordinate

- p:

-

Inclusion particle

- b:

-

Gas bubble

- in :

-

Inlet

- eff. :

-

Effective

- N :

-

Nozzle

- l :

-

Liquid phase

- g :

-

Gas phase

References

S. Lopez-Ramirez, R.D. Morales, J.A.R. Serrano, Numer. Heat Tr. A-Appl. 37, 69 (2000)

D.Y. Sheng, C.-S. Kim, J.-K. Yoon, T.-C. Hsiao, ISIJ Int. 38, 843 (1998)

D.Y. Sheng, L. Jonsson, Metall. Mater. Trans. B 31, 867 (2000)

H. Tozawa, Y. Kato, K. Sorimachi, T. Nakanishi, ISIJ Int. 39, 426 (1999)

J. Palafox-Ramos, J. De, S. López-Ramírez, R.D. Morales, Ironmak. Steelmak. 28, 101 (2001)

L. Zhang, Steel Res. Int. 76, 784 (2005)

P.K. Jha, P.S. Rao, A. Dewan, ISIJ Int. 48, 154 (2008)

Q. Yuan, B.G. Thomas, S.P. Vanka, Metall. Mater. Trans. B 35, 685 (2004)

Y. Miki, B.G. Thomas, Metall. Mater. Trans. B 30, 639 (1999)

A. Ramos-Banderas, R.D. Morales, J.D.J. Barreto, G. Solorio-Diaz, Steel Res. Int. 77, 325 (2006)

M. Warzecha, T. Merder, P. Warzecha, G. Stradomski, ISIJ Int. 53, 1983 (2013)

A. Rückert, M. Warzecha, R. Koitzsch, M. Pawlik, H. Pfeifer, Steel Res. Int. 80, 568 (2009)

A. Cwudziński, Steel Res. Int. 88, 1600484 (2017)

S. Chang, L. Zhong, Z. Zou, ISIJ Int. 55, 837 (2015)

ANSYS, Inc, Ansys® Academic Research Mechanical, Release Fluent 2019R2 (2019), https://www.ansys.com/products/fluids/ansys-fluent. Accessed 15 March 2021

ANSYS, Inc, Ansys® Academic Research Mechanical, Release ICEMCFD 2019R2 (2019), https://www.ansys.com/products/meshing. Accessed 15 March 2021

M.W. Reeks, On the dispersion of small particles suspended in an isotropic turbulent fluid. J. Fluid Mech. 83, 529 (1977)

C.T. Crowe, J.D. Schwarzkopf, M. Sommerfeld, Y. Tsuji, Multiphase Flows with Droplets and Particles, 2nd Edn. (CRC Press, Boca Raton, 2011)

A. Ramos-Banderas, R.D. Morales, L. García-Demedices, M. Díaz-Cruz, ISIJ Int. 43, 653 (2003)

R. Clift, J.R. Grace, M.E. Weber, Bubbles, Drops, and Particles (Dover Publications, Mineola, 1978)

L. Neves, R.P. Tavares, Analysis of the mathematical model of the gas bubbling curtain injection on the bottom and the walls of a continuous casting tundish. Ironmak. Steelmak. 44, 559 (2017)

L. Shiller, A. Naumann, Z. Ver. Dtsch. Ing. 77, 318 (1935)

B.E. Launder, D.B. Spalding, Comput. Method. Appl. M. 3, 269 (1974)

ANSYS, Inc, ANSYS Fluent 2019R2 theory guide (2019), https://ansyshelp.ansys.com. Accessed 15 March 2021

A.A. Troshko, Y.A. Hassan, Int. J. Multiphas. Flow 27, 1965 (2001)

A.D. Gosman, E. Ioannides, J. Energy 7, 482 (1983)

S.A. Morsi, A.J. Alexander, J. Fluid Mech. 55, 193 (1972)

C. Pfeiler, M. Wu, A. Ludwig, Mater. Sci. Eng. A 413–414, 115 (2005)

P.G. Saffman, J. Fluid Mech. 22, 385 (1965)

A. Li, G. Ahmadi, Aerosol. Sci. Tech. 16, 209 (1992)

L. Zhang, Y. Wang, JOM 64, 1063 (2012)

O.J. Ilegbusi, J. Szekely, Steel Res. 59, 399 (1988)

J. Szekely, O.J. Ilegbusi, The Physical and Mathematical Modeling of Tundish Operations (Springer-Verlag, Berlin, New York 1989)

S. Chakraborty, Y. Sahai, ISIJ Int. 31, 960 (1991)

R.D. Morales, S. Lopez-Ramirez, J. Palafox-Ramos, D. Zacharias, ISIJ Int. 39, 455 (1999)

M. Thumfart, A. Pelss, H. Pfeifer, Steel Res. Int. 90, 1800639 (2019)

S. Singh, S.C. Koria, ISIJ Int. 33, 1228 (1993)

K. Raghavendra, S. Sarkar, S.K. Ajmani, M.B. Denys, M.K. Singh, Appl. Math. Model. 37, 6284 (2013)

A.K. Sinha, Y. Sahai, ISIJ Int. 33, 556 (1993)

P.K. Jha, S.K. Dash, S. Kumar, ISIJ Int. 41, 1437 (2001)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, V.K., Jha, P.K. & Jain, P.K. Numerical Investigation on Gas Bubbling Assisted Inclusion Transport and Removal in Multistrand Tundish. Met. Mater. Int. 28, 2146–2165 (2022). https://doi.org/10.1007/s12540-021-01124-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01124-1