Abstract

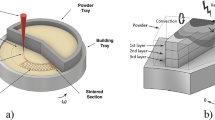

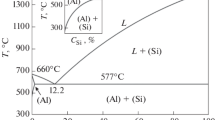

The synthesis features for 3D samples of AlSi10MgCu alloy were investigated. Two types of samples were used: single tracks and cubic samples of 10 mm3 volumes obtained by selective laser melting. 3D printing regimes and samples characteristics were compared for both types of samples. A comprehensive characterization of the initial AlSi10MgCu alloy powder was performed. The morphology, microstructure, and micro-hardness of the obtained single tracks and cubic samples were studied. The mechanism of the porosity formation was discussed in detail. A formation of pores and non–uniform structures was evidently caused by non–equilibrium crystallization during the selective laser melting process, namely 3D samples fast cooling. The lower porosity and the more uniform structure were obtained with higher values of laser power (from 220 to 240 W) Values of laser power had a crucial influence on the morphology and microstructure of the obtained 3D material. Optimal modes for selective laser melting for experimental AlSi10MgCu powder were revealed based on the microstructure and micro-hardness data. The values of the micro-hardness were varied from 115.5 to 151.1 HV. The micro-hardness for samples was increased on average by 20 HV after additional heat treatment. It was caused, most probably, by the separation of the Al2Cu phase.

Graphic Abstract

Similar content being viewed by others

References

M.C. Santos, A.R. Machado, W.F. Sales, M.A.S. Barrozo, E.O. Ezugwu, Int. J Adv. Manuf. Tech. 86, 3067 (2016)

A. Aversa, G. Marchese, A. Saboori, E. Bassini, D. Manfredi, S. Biamino, D. Ugues, P. Fino, M. Lombardi, Materials 12, 1007 (2019)

S.O. Rogachev, E.A. Naumova, E.S. Vasileva, M. Yu Magurina, R.V. Sundeev, A.A. Veligzhanin, Mater. Sci. Eng. A 767, 138410 (2019)

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, T.M. Pollock, Nature 549, 3659 (2017)

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, R. Hague, Prog. Mater. Sci. 106, 100578 (2019)

D. Manfredi, F. Calignano, M. Krishnan, R. Canali, E.P. Ambrosio, E. Atzeni, Materials 6, 856 (2013)

M.K. Surappa, Sadhana Acad. P. Eng. S. 28, 319 (2003)

J. Li, X. Cheng, Z. Li, X. Zong, S.-Q. Zhang, H.-M. Wang, Mater. Sci. Eng. A 735, 408 (2018)

U.K. Annigeri, G.B. Veeresh Kumar, Mater. Today Proc. 5, 11233 (2018)

P. Garg, A. Jamwal, D. Kumar, K.K. Sadasivuni, C.M. Hussain, P. Gupta, J. Mater. Res. Technol. 8, 4924 (2019)

D. Gu, Y. Yang, L. Xi, J. Yang, M. Xia, Opt. Laser Technol. 119, 105600 (2019)

X. Wen, Q. Wang, Q. Mu, N. Kang, S. Sui, H. Yang, X. Lin, W. Huang, Mater. Sci. Eng. A 745, 319 (2019)

A.Y. Nalivaiko, A.N. Arnautov, S.V. Zmanovsky, A.A. Gromov, Mater. Res. Express 6, 116580 (2019)

A.A. Gromov, A.Y. Nalivaiko, G.N. Ambaryan, M.S. Vlaskin, O.A. Buryakovskaya, S.A. Kislenko, A.Z. Zhuk, E.I. Shkolnikov, K.V. Slyusarskiy, A.A. Osipenkova, A.N. Arnautov, Materials 12, 3180 (2019)

A.Y. Nalivaiko, A.N. Arnautov, S.V. Zmanovsky, D.Y. Ozherelkov, P.K. Shurkin, A.A. Gromov, J. Alloy. Compd. 825, 154024 (2020)

W. Zhou, M. Dong, Z. Zhou, X. Sun, K. Kikuchi, N. Nomura, A. Kawasaki, Carbon 141, 67 (2019)

Y. Wang, J. Shi, S. Lu, W. Xiao, J. Micro Nano-Manuf. 6, 010902 (2018)

B. Chen, X. Xi, C. Tan, X. Song, Curr. Opin. Chem. Eng. 28, 28 (2020)

X. Han, H. Zhu, X. Nie, G. Wang, X. Zeng, Materials 11, 392 (2018)

H. Zhang, H. Zhu, T. Qi, Z. Hu, X. Zeng, Mater. Sci. Eng. A 656, 47 (2016)

P. Shurkin, T. Akopyan, N. Korotkova, A. Prosviryakov, A. Bazlov, A. Komissarov, D. Moskovskikh, Metals 10, 762 (2020)

R. Casati, M. Coduri, M. Riccio, A. Rizzi, M. Vedani, J. Alloy. Compd. 801, 243 (2019)

J. Zhang, B. Song, Q. Wei, D. Bourell, Y. Shi, J. Mater. Sci. Technol. 35, 270 (2019)

SLM Solutions, SLM®125 (2015), https://www.slm-solutions.com/products-and-solutions/machines/slm-125. Accessed 18 Aug 2021

EOS, EOS M 100 (2015). https://www.eos.info/en/additive-manufacturing/3d-printing-metal/eos-metal-systems/eos-m-100. Accessed 18 Aug 2021

A. Martin, M. San Sebastian, E. Gil, C.Y. Wang, S. Milenkovic, M.T. Pérez-Prado, C.M. Cepeda-Jiménez, Mater. Sci. Eng. A 819, 141487 (2021)

N.V. Dynin, V.V. Antipov, D.V. Khasikov, I. Benarieb, A.V. Zavodov, A.G. Evgenov, Mater. Lett. 284, 128898 (2021)

D.Y. Ozherelkov, S.A. Eremin, V.N. Anikin, S.V. Chernyshikhin, A.Y. Nalivaiko, A.A. Gromov, Mater. Chem. Phys. 267, 124673 (2021)

A.Y. Nalivaiko, A.N. Arnautov, S.V. Zmanovsky, A.A. Gromov, Mater. Res. Express 6, 086536 (2019)

J.-O. Andersson, T. Helander, L. Höglund, P.F. Shi, B. Sundman, Calphad 26, 273 (2002)

Thermo-calc software, TCAL4-TCS Al-based alloy database, Version 4.0. https://www.engineering-eye.com/THERMOCALC/details/db/pdf/thermo-calc/02/tcal40_extended_info.pdf. Accessed 1 Sept 2020

A.Y. Churyumov, A.V. Pozdniakov, A.S. Prosviryakov, I.S. Loginova, D.K. Daubarayte, D.K. Ryabov, V.A. Korolev, A.N. Solonin, M.D. Pavlov, S.V. Valchuk, Mater. Res. Express 6, 126595 (2019)

A. Aversa, M. Moshiri, E. Librera, M. Hadi, G. Marchese, D. Manfredi, M. Lorusso, F. Calignano, S. Biamino, M. Lombardi, M. Pavese, J. Mater. Process. Tech. 255, 17 (2018)

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft, N.M. Everitt, J. Mater. Process. Tech. 230, 88 (2016)

S. Shrestha, S. Rauniyar, K. Chou, J. Mater. Eng. Perform. 28, 611 (2019)

P. Wei, Z. Wei, Z. Chen, Y. He, J. Du, Appl. Phys. A 123, 604 (2017)

S.A. Khairallah, A. Anderson, J. Mater. Process. Tech. 214, 2627 (2014)

I. Yadroitsev, A. Gusarov, I. Yadroitsava, I. Smurov, J. Mater. Process. Tech. 210, 1624 (2010)

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft, N.M. Everitt, Mater. Sci. Eng. A 667, 139 (2016)

N.T. Aboulkhair, A. Stephens, I. Maskery, C. Tuck, I. Ashcroft, N.M. Everitt, Mechanical properties of selective laser melted AlSi10Mg: Nano, micro, and macro properties, in Proceedings of 26th Annual International Solid Freeform Fabrication Symposium - an Additive Manufacturing Conference, SFF 2015. Austin, 10-12 August 2015 (The University of Texas at Austin, Austin, 2020 ), pp. 1026–1035

C. Bruna-Rosso, A.G. Demir, B. Previtali, Mater. Design 156, 143 (2018)

X. Nie, H. Zhang, H. Zhu, Z. Hu, L. Ke, X. Zeng, J. Mater. Process. Tech. 256, 69 (2018)

S. Marola, D. Gianoglio, F. Bosio, A. Aversa, M. Lorusso, D. Manfredi, M. Lombardi, L. Battezzati, J. Alloy. Compd. 821, 153538 (2020)

U.S. Bertoli, A.J. Wolfer, M.J. Matthews, J.-P.R. Delplanque, J.M. Schoenung, Mater. Design 113, 331 (2017)

S.L. Campanelli, G. Casalino, N. Contuzzi, A. Angelastro, A.D. Ludovico, Analysis of the molten/solidified zone in selective laser melted parts, in Proceedings of SPIE, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications III, ed. by F. Dorsch. San Francisco, 4–6 February 2014, vol. 8963 (SPIE, Bellingham, 2014)

A.V. Pozdniakov, A.Y. Churyumov, I.S. Loginova, D.K. Daubarayte, D.K. Ryabov, V.A. Korolev, Mater. Lett. 225, 33 (2018)

D.R. Manca, A.Y. Churyumov, A.V. Pozdniakov, A.S. Prosviryakov, D.K. Ryabov, A.Y. Krokhin, V.A. Korolev, D.K. Daubarayte, Met. Mater. Int. 25, 633 (2019)

L.-Z. Wang, S. Wang, X. Hong, J. Manuf. Process. 35, 492 (2018)

F. Trevisan, F. Calignano, M. Lorusso, J. Pakkanen, A. Aversa, E.P. Ambrosio, M. Lombardi, P. Fino, D. Manfredi, Materials 10, 76 (2017)

Acknowledgements

This work is financially supported by the Russian Science Foundation (RSF), grant No. 19–79–30025.

Author information

Authors and Affiliations

Contributions

Conceptualization, AYN and DYO; Data curation, ANA and AVK; Formal analysis, AAG; Investigation, AEM, and IAP; Methodology, AYN, DYO and AEM; Supervision, AAG, ANA and AVK; Writing—original draft, AYN, SVC and DYO; Writing—review and editing, AAG All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nalivaiko, A.Y., Ozherelkov, D.Y., Pelevin, I.A. et al. Comprehensive Study of the 3D Printing of Single Tracks and Cubic Samples by Selective Laser Melting of AlSi10MgCu Alloy. Met. Mater. Int. 28, 787–801 (2022). https://doi.org/10.1007/s12540-021-01115-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01115-2