Abstract

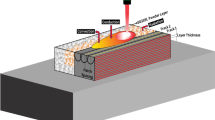

Laser surface texturing can improve the surface properties of the metallic components. In this work, surface texturing has been carried in a powder bed fusion of Inconel 718 (IN718) rather than material removal process. A 2D finite element method (FEM) has been built to simulate the thermo-fluidic dynamics of surface texturing, incorporating the phase-field method in the preplaced IN718 powder. The temperature and induced velocity fields have been predicted using transient heat transfer and fluid flow based on the conservation of mass, momentum, and energy in the melt pool. Furthermore, the roles of driving forces such as Marangoni force, recoil pressure, and thermal buoyancy force on the melt pool behavior have been evaluated. Micro-textures were developed using laser on the powder bed by using different scanning patterns, such as line, circle, hatch and convex dimple. The effect of process parameters (pitch distance, number of pulses and number of layers) on the surface hydrophobicity were evaluated by measuring the contact angle, where the convex dimple texture exhibited the maximum contact angle. The hydrophobicity was affected by the ripples (2nd level of roughness) on the surface, which increased with an increase in number of pulses.

Graphic abstract

Similar content being viewed by others

Data Availability

The data are available from the corresponding author upon reasonable request.

References

D.S. Patel, A. Singh, K. Balani, J. Ramkumar, Surf. Coat. Tech. 349, 816 (2018)

T. Bhardwaj, M. Shukla, N.K. Prasad, C.P. Paul, K.S. Bindra, Met. Mater. Int. 26, 1015 (2020)

Z. Lian, J. Xu, P. Yu, Z. Yu, Z. Wang, H. Yu, Met. Mater. Int. 26, 1603 (2020)

D.A. Del Cerro, G.R.B.E. Römer, A.J. Huis In’t Veld, Phycs. Proc. 5, 231 (2010)

I. Etsion, J. Tribol. 127, 248 (2005)

S. Bauer, P. Schmuki, K.V.D. Mark, J. Park, Prog. Mater. Sci. 58, 261 (2013)

D.G. Coblas, A. Fatu, A. Maoui, M. Hajjam, P. I. Mech. Eng. J-J. Eng. 229, 3 (2015)

A. Marmur, Biofouling 22, 107 (2006)

A. Arslan, H.H. Masjuki, M.A. Kalam, M. Varman, R.A. Mufti, M.H. Mosarof, L.S. Khuong, M.M. Quazi, Crit. Rev. Solid State Mater. Sci. 41, 447 (2016)

S. Sharma, V. Mandal, S.A. Ramakrishna, J. Ramkumar, J. Manuf. Process. 39, 282 (2019)

M. Tang, V. Shim, Z.Y. Pan, Y.S. Choo, M.H. Hong, J. Laser Micro Nanoen. 6, 6 (2011)

A.M. Kietzig, S.G. Hatzikiriakos, P. Englezos, Langmuir 25, 4821 (2009)

P. Bizi-Bandoki, S. Benayoun, S. Valette, B. Beaugiraud, E. Audouard, Appl. Surf. Sci. 257, 5213 (2011)

V. Mandal, S. Sharma, J. Ramkumar, Advances in simulation, product design and development, ed. by M.S. Shunmugam, M. Kanthababu (Springer, Singapore, 2020), p. 241

S.K. Sharma, K. Biswas, J.D. Majumdar, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00884-6

X. Wang, Y. Zhang, L. Wang, J. Xian, M. Jin, M. Kang, Appl. Phys. A 123, 51 (2017)

J. Zhou, H. Shen, Y. Pan, X. Ding, Opt. Lasers Eng. 78, 113 (2016)

M. Simonelli, Y.Y. Tse, C. Tuck, Metall. Mater. Trans. A 45, 2863 (2014)

A. Sarker, N. Tran, A. Rifai, J. Elambasseril, M. Brandt, R. Williams, M. Leary, K. Fox, Mater. Design 154, 326 (2018)

L. Jiao, Z.Y. Chua, S.K. Moon, J. Song, G. Bi, H. Zheng, Nanomaterials 8, 601 (2018)

M. Wang, Y. Wu, S. Lu, T. Chen, Y. Zhao, H. Chen, Z. Tang, Prog. Nat. Sci. Mater. Int. 26, 671 (2016)

N. Otero, P. Romero, A. Gonzalez, A. Scano, J. Laser Micro Nanoen. 7, 152 (2012)

P. Romeroa, N. Otero, A. González, G. García, A. Scano, Phycs. Proc. 12, 277 (2011)

G.P. Dinda, A.K. Dasgupta, J. Mazumder, Scripta Mater. 67, 503 (2012)

H.L. Wei, J. Mazumder, T. DebRoy, Sci. Rep. 5, 16446 (2015)

X. Zhou, K. Li, D. Zhang, X. Liu, J. Ma, W. Liu, Z. Shen, J. Alloy. Compd. 631, 153 (2015)

I. Yadroitsava, J. Els, G. Booysen, I. Yadroitsev, S. Afr. J. Ind. Eng. 26, 86 (2015)

P. Tang, S. Wang, H. Duan, M. Long, Y. Li, S. Fan, D. Chen, Jom 72, 1128 (2020)

S. Sharma, V. Mandal, S.A. Ramakrishna, J. Ramkumar, J. Mater. Process. Tech. 262, 131 (2018)

C.D. Boley, S.A. Khairallah, A.M. Rubenchik, Appl. Opt. 54, 2477 (2015)

P. Tang, H. Xie, S. Wang, X. Ding, Q. Zhang, H. Ma, J. Yang, S. Fan, M. Long, D. Chen, X. Duan, Metall. Mater. Trans. B 50, 2273 (2019)

B. Singh, P. Singhal, K.K. Saxena, R.K. Saxena, Met. Mater. Int. 27, 2848 (2021)

R. Rai, T.A. Palmer, J.W. Elmer, T. Debroy, Weld. J. 88, 54 (2009)

M. Courtois, M. Carin, P. Le Masson, S. Gaied, M. Balabane, J. Phys. D Appl. Phys. 46, 505305 (2013)

Y. Zhang, Z. Shen, X. Ni, Int. J. Heat Mass Transf. 73, 429 (2014)

H. Shen, D. Feng, Z. Yao, J. Manuf. Sci. Eng. 139, 041008 (2016)

J. Kim, S. Lee, Y. Choi, S.M. Lee, D. Jeong, Math. Probl. Eng. 2016, 9532608 (2016)

R. Jafari, T. Okutucu-Özyurt, J. Comput. Multiph. Flows. 7, 143 (2015)

P. Yue, J.J. Feng, C. Liu, J. Shen, J. Fluid Mech. 515, 293 (2004)

X. Yang, Y. Fu, X. Kuang, Met. Mater. Int. 27, 4225 (2021)

K. Hirano, R. Fabbro, M. Muller, J. Phys. D Appl. Phys. 44, 435402 (2011)

S.I. Anisimov, Sov. Phys. JETP 27, 182 (1968)

K. Nogi, K. Ogino, A. McLean, W.A. Miller, Metall. Trans. B 17, 163 (1986)

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, A.M. Rubenchik, J. Mater. Process. Tech. 214, 2915 (2014)

G.L. Knapp, N. Raghavan, A. Plotkowski, T. DebRoy, Addit. Manuf. 25, 511 (2019)

A. Bauereiß, T. Scharowsky, C. Körner, J. Mater. Process. Tech. 214, 2522 (2014)

G. Nagayama, D. Zhang, Soft Matter 16, 3514 (2020)

A.A. Savchenko, A.I. Belyaeva, A.A. Galuza, I.V. Kolenov, J. Appl. Phys. 125, 065307 (2019)

J. Song, Y. Chew, G. Bi, X. Yao, B. Zhang, J. Bai, S. Ki, Mater. Design 137, 286 (2018)

M. Bayat, S. Mohanty, J.H. Hattel, Int. J. Heat Mass Transf. 139, 95 (2019)

Acknowledgements

The authors would like to thank Mr. Gopinath Sahu for his help on contact angle measurements of the samples at IIT Kanpur. The authors would like to express their thanks to the financial assistance provided by the Institute and equipment purchased from the project supported by BIRAC/DBT (BT/NBM0127/03/18).

Funding

Financial assistance provided by the Institute and equipment purchased from the project supported by BIRAC/DBT (BT/NBM0127/03/18).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mandal, V., Sharma, S., Singh, S.S. et al. Laser Surface Texturing in Powder Bed Fusion: Numerical Simulation and Experimental Characterization. Met. Mater. Int. 28, 181–196 (2022). https://doi.org/10.1007/s12540-021-01072-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01072-w