Abstract

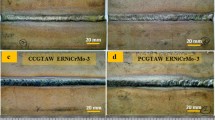

In this study, the effect of Nb content and aging temperature on the weld of Inconel 690 was investigated by the behavior of \({\text{M}}_{23} {\text{C}}_{6}\). After changing the Nb content of FM-52 to 0.65 wt%, 1.48 wt%, 2.45 wt%, and 3.46 wt%, shielded metal arc welding was conducted under constrained conditions to reduce the thermal deformation. As a result of measuring the hardness after aging treatment, the hardness increased with the Nb content, and it was determined that the transgranular and intergranular precipitation effect of MC on the increase in hardness was greater than that of \({\text{M}}_{23} {\text{C}}_{6}\), which mainly precipitated at the migrated grain boundary (MGB) compared to MC. Optical Microscope analysis showed that the MGB changed from a straight type to a vermicular type as the Nb content increased. As a result of SEM/EDS and EBSD analysis, most of the carbide (\({\text{M}}_{23} {\text{C}}_{6}\)) was observed in specimen A with a low Nb content and decreased with an increase in the aging temperature, and the fraction of \({\text{M}}_{23} {\text{C}}_{6}\) decreased with an increase in the Nb content. Micro-voids were generated by a large amount of \({\text{M}}_{23} {\text{C}}_{6}\) at an aging temperature of 600–800 °C in the A and B specimens with a relatively low Nb content. The pitting resistance was improved due to the amount of Cr-rich \({\text{M}}_{23} {\text{C}}_{6}\) decreased as the Nb content increased. However, no decrease in corrosion resistance was observed owing to the micro-voids produced near Cr-rich \({\text{M}}_{23} {\text{C}}_{6}\).

Graphic Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce findings of this study cannot be shared at this time because of legal or ethical reasons.

References

J.B. Ferguson, H.F. Lopez, Metall. Mater. Trans. A 37, 2471 (2006)

N.E. Nissley, J.C. Lippold, Weld. J. 87, 257 (2008)

S. Nam, C. Kim, Y.-M. Kim, J. Weld. Join. 35, 7 (2017)

R.J. Lemire, G.A. McRae, J. Nucl. Mater. 294, 141 (2001)

J.J. Kai, G.P. Yu, C.H. Tsai, M.N. Liu, S.C. Yao, Metall. Trans. A 20, 2057 (1989)

A.J. Ramirez, J.C. Lippold, Mater. Sci. Eng. A 380, 259 (2004)

W. Mo, S. Lu, D. Li, Y. Li, Mater. Sci. Eng. A 582, 326 (2013)

C. Hua, H. Lu, C. Yu, J. Chen, X. Wei, J. Xu, J. Mater. Process. Tech. 239, 240 (2017)

A.J. Ramirez, J.C. Lippold, in Hot Cracking Phenomena in Welds, ed. by T. Boellinghaus, H. Herold (Springer, Berlin, Heidelberg, 2005), pp. 19–41

X. Wei, M. Xu, J. Chen, C. Yu, J. Chen, H. Lu, J. Xu, Mater. Charact. 145, 65 (2018)

T. Baldrige, G. Poling, E. Foroozmehr, R. Kovacevic, T. Metz, V. Kadekar, M. C. Gupta, Opt. Laser. Eng. 51, 180 (2013)

M.G. Collins, A.J. Ramirez, J.C. Lippold, Weld. J. 83, 31 (2004)

A.J. Ramirez, J.C. Lippold, Mater. Sci. Eng. A 380, 245 (2004)

A.J. Ramirez, C.M. Garzon, in Hot Cracking Phenomena in Welds II, ed. by T. Boellinghaus, H. Herold, C.E. Cross, J.C. Lippold (Springer, Berlin, Heidelberg, 2008), pp. 427–453

W. Mo, S. Lu, D. Li, Y. Li, Metall. Mater. Trans. A 45, 5114 (2014)

T.H. Lee, Y.J. Lee, S.H. Joo, H.H. Nersisyan, K.T. Park, Metall. Mater. Trans. A 46, 4020 (2015)

H. Li, S. Xia, B. Zhou, J. Peng, Mater. Charact. 81, 1 (2013)

R. Hu, G. Bai, J. Li, J. Zhang, T. Zhang, H. Fu, Mater. Sci. Eng. A 548, 83 (2012)

D.J. Lee, Y.S. Kim, Y.T. Shin, E.C. Jeon, S.H. Lee, H.-J. Lee, S.K. Lee, J.H. Lee, H.W. Lee, Met. Mater. Int. 16, 813 (2010)

N.E. Nissley, J.C. Lippold, Weld. J. 88, 131 (2009)

R. Qin, H. Wang, G. He, Metall. Mater. Trans. A 46, 1227 (2015)

S. Kou, Welding Metallurgy, 2nd edn. (Wiley, New Jersey, 2003), pp.375-392

W. Mo, S. Lu, D. Li, Y. Li, J. Mater. Sci. Technol. 29, 458 (2013)

A.Y. Jang, D.J. Lee, S.H. Lee, J.H. Shim, S.W. Kang, H.W. Lee, Mater. Design 32, 371 (2011)

H.T. Lee, S.L. Jeng, T.Y. Kuo, Metall. Mater. Trans. A 34, 1097 (2003)

W.V. Youdelis, O. Kwon, Met. Sci. 17, 385 (1983)

W. Wu, C.H. Tsai, Metall. Mater. Trans. A 30, 417 (1999)

B. Piekarski, Mater. Charact. 61, 899 (2010)

B. Sasmal, J. Mater. Sci. 32, 5439 (1997)

E.A. Trillo, L.E. Murr, J. Mater. Sci. 33, 1263 (1998)

T. Shibata, T. Iron Steel I. Jpn. 23, 785 (1983)

J.W. Han, S.H. Jung, H. Cho, H.W. Lee, Int. J. Electrochem. Sci. 13, 2829 (2018)

J.B. Lee, Mater. Chem. Phys. 99, 224 (2006)

A. Maniee, F. Mahboubi, R. Soleimani, Met. Mater. Int. 26, 1664 (2020)

C.S. Kiminami, C.A.C. Souza, L.F. Bonavina, L.R.P. de Andrade Lima, S. Suriñach, M.D. Baró, C. Bolfarini, W.J. Botta, J. Non-Cryst. Solids 356, 2651 (2010)

Acknowledgements

This study was supported by Dong-A University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, C., Kim, D. & Lee, H. Carbide Behavior and Micro-void of Inconel 690 According to Nb Content and Aging Temperature. Met. Mater. Int. 27, 4681–4699 (2021). https://doi.org/10.1007/s12540-021-01028-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01028-0