Abstract

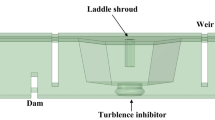

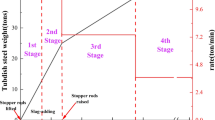

With globalization and increased competitiveness in the steel market, industries are required to produce quality steel at a reasonable cost. This necessitates the introduction of either new manufacturing techniques, or to improve quality and yield with the existing processes. It is well established that slags entrapped by the vortexing phenomenon during steelmaking processes are responsible for causing quality issues and lowering the yield of steel produced. Measures are taken to end teeming from tundish before initiation of vortexing to prevent slag entrainment. This premature end of teeming is an inevitable yield loss that needs to be minimized. The present work aims to increase the efficiency of the steelmaking process by control techniques for minimizing tundish slag entrainment during tundish teeming. Experimental and mathematical simulations with different tundish configurations have been carried out to analyze the initiation of slag vortexing. The mathematical simulation uses multiphase models with a steel–slag–air system while the physical simulation uses a water–paraffin oil system to replicate the steel–slag system. It has been observed that the presence of higher turbulence and a thicker slag layer over liquid steel increases vortex initiation height (Hcr). An empirical correlation between these parameters with Hcr has been developed to optimize the end of teeming and increase process yield.

Graphic abstract

Similar content being viewed by others

References

Y. Sahai, E. Toshihiko, ISIJ Int. 36, 667 (1996)

D. Mazumdar, Steel Res. Int. 90, 1800279 (2019)

S.R. Dolan, E.S. Oliveria, Phys. Rev. D 87, 124038 (2013)

D.P. Tan, P.Y. Li, Y.X. Ji, D.H. Wen, C. Li, IEEE T. Ind. El. Con. In. 60, 4702 (2013)

D. Li, D. Tan, D.L. Li, S. Zhang, Y. Zhu, Z. Yin, Int. J. Heat Mass Trans. 150, 119250 (2020)

S.J. Lee, S.J. Kim, H.G. Lee, Met. Mater. Int. 22, 136 (2016)

K. Kuwana, M.I. Hassan, P.K. Singh, K. Saito, J. Nakagawa, Mater. Manuf. Process. 2, 407 (2008)

P. Ni, L.T.I. Jonsson, P.G. Jonsson, Steel Res. Int. 84, 276 (2012)

R.D. Morales, O. Dávila-Maldonado, I. Calderon, K. Morales-Higa, ISIJ Int. 53, 782 (2013)

D. Tan, Y. Ni, L. Zhang, J. Iron Steel Res. Int. 24, 669 (2017)

R.D. Morales, S.G. Hernandez, J.D.J. Barreto, A.C. Huerta, I.C. Ramos, E. Gutierrez, Metall. Mater. Trans. B 47, 2595 (2016)

J.H. Ahn, J.K. Yoon, J.E. Lee, Met. Mater. Int. 8, 271 (2002)

K. Michalek, K. Gryc, L. Socha, M. Tkadleckova, M. Saternus, J. Pieprzyca, T. Merder, L. Pindor, Arch. Metall. Mater. 62, 1469 (2017)

A. Mabentsela, G. Akdogan, S. Bradshaw, J. South. Afr. Inst. Min. Metall. 117, 469 (2017)

S.G. Hernandez, J.J. Barreto, J.A. Ramos-Banderas, G. Solorio-Diaz, Steel Res. Int. 81, 453 (2010)

S. Pirker, Steel Res. Int. 81, 623 (2010)

S.G. Hernandez, G. Solorio-Diaz, J.A. Ramos-Banderas, J.J. Barreto, R.D. Morales, Steel Res. Int. 80, 256 (2009)

G. Solorio-Diaz, J.A. Ramos-Banderas, J.J. Barreto, R.D. Morales, Steel Res. Int. 78, 248 (2007)

K. Krishnapisharody, G.A. Irons, Metall. Mater. Trans. B 37, 763 (2006)

K. Chatopadhyay, M. Isac, R.I.L. Guthrie, ISIJ Int. 50, 331 (2010)

R. Sankaranarayanan, R.I.L. Guthrie, Ironmak. Steelmak. 29, 147 (2002)

T. Merder, M. Saternus, M. Warzecha, P. Warzecha, Metalurgija 53, 323 (2014)

H.X. Li, Q. Wang, H. Lei, J.W. Jiang, Z.C. Guo, J.C. He, ISIJ Int. 56, 94 (2016)

S. Pirker, M. Lechner, G. Ernst, Int. J. Cast Metal. Res. 22, 244 (2009)

Ansys Inc., Release 18.2 (ANSYS Fluent Theory Guide, 2017), pp. 39–138

Acknowledgements

The authors would like to thank the management of RDCIS, SAIL for granting permission to publish this document.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, A., Kumar, R. & Singh, R.K. Assessment of Critical Vortexing Height to Prevent Slag Entrapment During Tundish Teeming. Met. Mater. Int. 28, 1246–1256 (2022). https://doi.org/10.1007/s12540-021-01014-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01014-6