Abstract

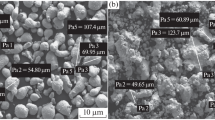

The effect of 0.25, 0.5 and 1 wt% Ni addition on the impression creep behavior of the cast A356 alloy was investigated. Optical and scanning electron microscopy (SEM) equipped with energy dispersive spectrometry (EDS) were used for examination of the microstructure. The alloy’s creep properties were investigated using the impression creep technique under normalized stress of 0.022–0.03 (corresponding to 600–675 MPa) and temperature of 473–513 K. The results showed that the creep properties of A356 alloy were improved by the addition of Ni. The improved creep properties were attributed to the modification of eutectic silicon and the formation of Ni-rich intermetallics. Calculating the values of stress exponent (n) and creep activation energy (Q) indicated that the dominant mechanism was the lattice self-diffusion climb controlled and Ni had no effect on the creep mechanism.

Graphic Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

References

F. Paray, J.E. Gruzleski, Cast Metals 7, 29 (1994)

F. Paray, J.E. Gruzleski, Cast Metals 7, 153 (1994)

S. Rashno, K. Ranjbar, M. Reihanian, Mater. Res. Express 6, 0865–0866 (2019)

M. Javidani, D. Larouche, Int. Mater. Rev. 59, 132 (2014)

D.H. Qigui Wang, X. Yan, F. Caron, in AFS Proceedings of 122nd Metalcasting Congress Fort Worth, Texas, Paper 18-034 (2018)

M. Garat, Int. J. Metalcast. 5, 17 (2011)

S. Rashno, M. Reihanian, K. Ranjbar, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00562-2

A. Farkoosh, X.G. Chen, M. Pekguleryuz, Mater. Sci. Eng. A 620, 181 (2015)

M. Reihanian, K. Ranjbar, S. Rashno, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00628-6

K.E. Knipling, D.C. Dunand, D.N. Seidman, Zeitschrift für Metallkunde 97, 246 (2006)

J. Feng, B. Ye, L. Zuo, R. Qi, Q. Wang, H. Jiang, R. Huang, W. Ding, Mater. Sci. Eng. A 706, 27 (2017)

T. Bogdanoff, A.K. Dahle, S. Seifeddine, Int. J. Metalcast. 12, 434 (2018)

H. Medrano-Prieto, C. Garay-Reyes, C. Gómez-Esparza, I. Estrada-Guel, J. Aguilar-Santillan, M. Maldonado-Orozco, R. Martínez-Sánchez, Mater. Charact. 120, 168 (2016)

Z. Asghar, G. Requena, F. Kubel, Mater. Sci. Eng. A 527, 5691 (2010)

Y. Yang, K. Yu, Y. Li, D. Zhao, X. Liu, Mater. Design 33, 220 (2012)

P. Pandee, U. Patakham, C. Limmaneevichitr, J. Alloy. Compd. 728, 844 (2017)

C. Xu, W. Xiao, S. Hanada, H. Yamagata, C. Ma, Mater. Charact. 110, 160 (2015)

C. Xu, F. Wang, H. Mudassar, C. Wang, S. Hanada, W. Xiao, C. Ma, J. Mater. Eng. Perform. 26, 1605 (2017)

J.A. Taylor, Procedia Mater. Sci. 1, 19 (2012)

L. Lu, A. Dahle, Metall. Mater. Trans. A 36, 819 (2005)

Z. Ma, S. Tjong, Mater. Sci. Eng. A 256, 120 (1998)

J. Čadek, M. Pahutova, V. Šustek, Mater. Sci. Eng. A 246, 252 (1998)

J. Porter, F. Humphreys, Met. Sci. 13, 83–88 (1979)

K.K. Chawla, M. Meyers, Mechanical Behavior of Materials (Prentice Hall, Upper Saddle River, 1999), pp. 653–659

B. Kondori, R. Mahmudi, Metall. Mater. Trans. A 40, 2007 (2009)

C. Park, X. Long, S. Haberman, S. Ma, I. Dutta, R. Mahajan, S. Jadhav, J. Mater. Sci. 42, 5182 (2007)

G. Cseh, J. Bär, H.-J. Gudladt, J. Lendvai, A. Juhasz, Mater. Sci. Eng. A 272, 145 (1999)

D. Dorner, K. Röller, B. Skrotzki, B. Stöckhert, G. Eggeler, Mater. Sci. Eng. A 357, 346 (2003)

D. Sastry, Mater. Sci. Eng. A 409, 67 (2005)

R. Gupta, B. Daniel, Mater. Sci. Eng. A 733, 257 (2018)

H.J. Frost, M.F. Ashby, Deformation Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon press, Oxford, 1982), pp. 82–89

F. Yang, J. Li, C. Shih, Mater. Sci. Eng. A 201, 50 (1995)

J. Li, X. Wang, T. Ludwig, Y. Tsunekawa, L. Arnberg, J. Jiang, P. Schumacher, Acta Mater. 84, 153 (2015)

S.-Z. Lu, A. Hellawell, Metall. Trans. A 18, 1721 (1987)

M. Timpel, N. Wanderka, R. Schlesiger, T. Yamamoto, N. Lazarev, D. Isheim, G. Schmitz, S. Matsumura, J. Banhart, Acta Mater. 60, 3920 (2012)

H. Yang, D. Watson, Y. Wang, S. Ji, J. Mater. Sci. 49, 8412 (2014)

V.S. Zolotorevsky, N.A. Belov, M.V. Glazoff, Casting Aluminum Alloys (Elsevier, Amsterdam, 2007), pp. 367–376

T.O. Mbuya, B.O. Odera, S.P. Ng'ang'a, Int. J. Cast Metal. Res. 16, 451 (2003)

Y. Li, Y. Yang, Y. Wu, L. Wang, X. Liu, Mater. Sci. Eng. A 527, 7132 (2010)

S. Zhu, J. Nie, B. Mordike, Metall. Mater. Trans. A 37, 1221 (2006)

S.M. Miresmaeili, B. Nami, R. Abbasi, I. Khoubrou, JOM 71, 2128 (2019)

B.A. Esgandari, B. Nami, M. Shahmiri, A. Abedi, Trans. Nonferr. Metal. Soc. 23, 2518 (2013)

L.E. Murr, Interfacial Phenomena in Metals and Alloys (Addison-Wesley, Boston, 1975), pp. 271–294

M. Faraji, H. Khalilpour, J. Mater. Eng. Perform. 23, 3467 (2014)

Acknowledgements

The authors gratefully acknowledge the support extended by the Department of Mechanical Engineering, Aligudarz branch, Islamic Azad University, Aligudarz, Iran

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Varmazyar, M., Yousefzadeh, S. & Sheikhi, M.M. Effect of Ni on Microstructure and Creep Behavior of A356 Aluminum Alloy. Met. Mater. Int. 28, 579–588 (2022). https://doi.org/10.1007/s12540-020-00892-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00892-6