Abstract

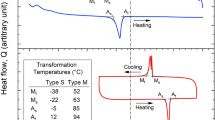

Using a combination of tests and numerical simulations, the fatigue behaviors of a Ni-based single crystal (SC) alloy with different surface roughnesses (SRs) are studied. The test results demonstrate that the fatigue life decreases with increasing SR, while the strain accumulation shown an opposite trend. Surface defects can give rise to the nucleation, aggregation and growth of surface cracks, which are the principal inducement of fatigue failure. Finite element models of the actual surface topography were established, and the notched plate models whose modelling parameters were determined by the SR parameters (\(R_{z}\), \(R_{sm}\), \(R_{a}\)) were used to equivalently simplify, the equivalent errors are within 5%. In addition, a semi-empirical formula between the surface stress concentration factor (\(K_{t}\)) and the SR parameters was fitted. By introducing the \(K_{t}\) expressed by the SR parameters into a fatigue damage model based on crystal plasticity theory, a fatigue life prediction method of a Ni-based SC alloy that considers SR was established, and it has been verified to exhibit excellent consistency with the test results.

Graphic Abstract

Similar content being viewed by others

References

L. Zhang, Z. Huang, L. Jiang et al., Effect of Mo: W ratio on segregation behavior and creep strength of nickel-based single crystal superalloys. Mater. Sci. Eng. A 744, 481–489 (2019)

C. Ludwig, F. Rabold, M. Kuna et al., Simulation of anisotropic crack growth behavior of nickel base alloys under thermomechanical fatigue. Eng. Fract. Mech. 224, 106800 (2020)

Z. Wen, D. Zhang, S. Li et al., Anisotropic creep damage and fracture mechanism of nickel-base single crystal superalloy under multiaxial stress. J. Alloy. Compd. 692, 301–312 (2017)

J.S. Van Sluytman, A.L. Fontaine, J.M. Cairney et al., Elemental partitioning of platinum group metal containing Ni-base superalloys using electron microprobe analysis and atom probe tomography. Acta Mater. 58(6), 1952–1962 (2010)

B. Salehnasab, E. Poursaeidi, Mechanism and modeling of fatigue crack initiation and propagation in the directionally solidified CM186 LC blade of a gas turbine engine. Eng. Fract. Mech. 225, 106842 (2019)

G.-J. Yuan, X.-C. Zhang, B. Chen et al., Low-cycle fatigue life prediction of a polycrystalline nickel-base superalloy using crystal plasticity modelling approach. J. Mater. Sci. Technol. 38, 28–38 (2020)

A.R. Balachandramurthi, J. Moverare, N. Dixit et al., Influence of defects and as-built surface roughness on fatigue properties of additively manufactured Alloy 718. Mater. Sci. Eng. A 735, 463–474 (2018)

A.H. Chern, N. Peeyush, M. Robert et al., Build orientation, surface roughness, and scan path influence on the microstructure, mechanical properties, and flexural fatigue behavior of Ti–6Al–4V fabricated by electron beam melting. Mater. Sci. Eng. A 772, 138740 (2020)

R. Shrestha, J. Simsiriwong, N. Shamsaei, Fatigue behavior of additive manufactured 316L stainless steel parts: effects of layer orientation and surface roughness. Addit. Manuf. 28, 23–38 (2019)

K. Singh, F. Sadeghi, M. Correns et al., A microstructure based approach to model effects of surface roughness on tensile fatigue. Int. J. Fatigue 129, 105229 (2019)

M. Nakatani, H. Masuo, Y. Tanaka et al., Effect of surface roughness on fatigue strength of Ti–6Al–4V alloy manufactured by additive manufacturing. Proc. Struct. Integ. 19, 294–301 (2019)

H. Zhang, A. Armstrong, P. Müllner, Effects of surface modifications on the fatigue life of unconstrained Ni–Mn–Ga single crystals in a rotating magnetic field. Acta Mater. 155, 175–186 (2018)

V. Martín, J. Vázquez, C. Navarro et al., Effect of shot peening residual stresses and surface roughness on fretting fatigue strength of Al 7075-T651. Tribol. Int. 142, 106004 (2020)

S. Sarkar, C.S. Kumar, A.K. Nath, Effects of different surface modifications on the fatigue life of selective laser melted 15–5 PH stainless steel. Mater. Sci. Eng. A 762, 138109 (2019)

C. Yao, J. Lin, D. Wu et al., Surface integrity and fatigue behavior when turning γ-TiAl alloy with optimized PVD-coated carbide inserts. Chin. J. Aeronaut. 31(4), 826–836 (2018)

T. Yuri, Y. Ono, T. Ogata, Effects of surface roughness and notch on fatigue properties for Ti–5Al–2.5Sn ELI alloy at cryogenic temperatures. Sci. Technol. Adv. Mater. 4(4), 291–299 (2003)

J. Günther, S. Leuders, P. Koppa et al., On the effect of internal channels and surface roughness on the high-cycle fatigue performance of Ti–6Al–4V processed by SLM. Mater. Des. 143, 1–11 (2018)

S. Pomberger, M. Leitner, M. Stoschka, Evaluation of surface roughness parameters and their impact on fatigue strength of Al-Si cast material. Mater. Today: Proc. 12, 225–234 (2019)

Y.X. Gao, J.Z. Yi, P.D. Lee et al., A micro-cell model of the effect of microstructure and defects on fatigue resistance in cast aluminum alloys. Acta Mater. 52(19), 5435–5449 (2004)

Y. Aono, H. Noguchi, Fatigue limit reliability of axisymmetric complex surface. Int. J. Fracture 131(1), 59–78 (2005)

D. Arola, C.L. Williams, Estimating the fatigue stress concentration factor of machined surfaces. Int. J. Fatigue 24(9), 923–930 (2002)

B. Zhang, H. Liu, H. Bai et al., Ratchetting–multiaxial fatigue damage analysis in gear rolling contact considering tooth surface roughness. Wear 428–429, 137–146 (2019)

S.K. As, B. Skallerud, B.W. Tveiten, Surface roughness characterization for fatigue life predictions using finite element analysis. Int. J. Fatigue 30(12), 2200–2209 (2008)

Z. Cheng, R. Liao, W. Lu, Surface stress concentration factor via Fourier representation and its application for machined surfaces. In. J. Solids. Struct. 113–114, 108–117 (2017)

J. Zhang, A. Fatemi, Surface roughness effect on multiaxial fatigue behavior of additive manufactured metals and its modeling. Theor. Appl. Fract. Mech. 103, 102260 (2019)

M. Suraratchai, J. Limido, C. Mabru et al., Modelling the influence of machined surface roughness on the fatigue life of aluminium alloy. Int. J. Fatigue 30(12), 2119–2126 (2008)

G.I. Taylor, The mechanism of plastic deformation of crystals. Part I. Theoretical [M], in Proceedings of the Royal Society of London. Series A, Containing Papers of a Mathematical and Physical Character (1934)

R. Hill, Generalized constitutive relations for incremental deformation of metal crystals by multislip. J. Mech. Phys. Solids 14(2), 95–102 (1966)

R. Hill, J.R. Rice, Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids 20(6), 401–413 (1972)

J.L. Bassani, T.Y. Wu, Latent hardening in single crystals. II. Analytical characterization and predictions. Proc. Roy. Soc. A: Math. Phys. Eng. Sci. 435(93), 21–41 (1991)

V. Levkovitch, R. Sievert, B. Svendsen, Simulation of deformation and lifetime behavior of a fcc single crystal superalloy at high temperature under low-cycle fatigue loading. Int. J. Fatigue 28(12), 1791–1802 (2006)

Z. Wen, H. Pei, H. Yang et al., A combined CP theory and TCD for predicting fatigue lifetime in single-crystal superalloy plates with film cooling holes. Int. J. Fatigue 111, 243–255 (2018)

J. Wang, Z. Wen, X. Zhang et al., Effect mechanism and equivalent model of surface roughness on fatigue behavior of nickel-based single crystal superalloy. Int. J. Fatigue 125, 101–111 (2019)

S. Sreenivasan, S.K. Mishra, K. Dutta, Ratcheting strain and its effect on low cycle fatigue behavior of Al 7075-T6 alloy. Mater. Sci. Eng. A 698, 46–53 (2017)

S.K. Paul, S. Sivaprasad, S. Dhar et al., Ratcheting and low cycle fatigue behavior of SA333 steel and their life prediction. J. Nucl. Mater. 401(1), 17–24 (2010)

D. Novovic, R.C. Dewes, D.K. Aspinwall et al., The effect of machined topography and integrity on fatigue life. Int. J. Mach. Tools Manuf. 44(2–3), 125–134 (2004)

T. Zhou, H. Ding, X. Ma et al., Microstructure and stress-rupture life of high W-content cast Ni-based superalloy after 1000–1100 °C thermal exposures. Mater. Sci. Eng. A 725, 299–308 (2018)

G. Owolabi, O. Okeyoyin, O. Bamiduro et al., Fatigue strength reduction factor for polycrystalline nickel base superalloy with and without non-metallic inclusions. Proc. Eng. 74, 297–302 (2014)

L.T. Lu, J.W. Zhang, K. Shiozawa, Influence of inclusion size on S–N curve characteristics of high-strength steels in the giga-cycle fatigue regime. Fatigue. Fract. Eng. Mater. Struct. 32(8), 647–655 (2009)

S. Saberifar, A.R. Mashreghi, M. Mosalaeepur et al., The interaction between non-metallic inclusions and surface roughness in fatigue failure and their influence on fatigue strength. Mater. Des. 35, 720–724 (2012)

A. Majumdar, C.L. Tien, Fractal charaterization and simulation of rough surfaces. Wear 136(2), 313–327 (1990)

Y. Zhang, Z. Wen, H. Pei et al., Equivalent method of evaluating mechanical properties of perforated Ni-based single crystal plates using artificial neural networks. Comput. Method. Appl. Mech. 360, 112725 (2020)

H. Neuber, Theory of Notch Stresses (Spring Verlag, Berlin, 1958)

Acknowledgements

The research was supported by the National Natural Science Foundation of China (NO.51875461, 51875462), the Fundamental Research Funds for the Central Universities (3102019PY001) and National Science and Technology Major Project (2017-IV-0003-0040, 2017-V-0003-0052).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J.J., Wen, Z.X., Zhang, Y.M. et al. Experimental Characterization and Computational Modelling for Fatigue Behavior of a Ni-Based Single Crystal Alloy Considering Surface Roughness. Met. Mater. Int. 27, 4383–4396 (2021). https://doi.org/10.1007/s12540-020-00784-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00784-9