Abstract

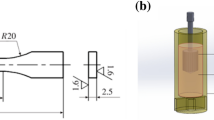

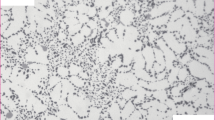

The Aluminum–Silicon (Al–Si) die-casting alloys, such as the commercial A356 alloy, are expected to be used in heat-sink and the device with high thermal conductivity due to their high production efficiency of casting process. These fields also required them to possess sound mechanical properties. To meet these demands, the Strontium (Sr) was often utilized to modify the silicon phase. According to our current work, the secondary dendrite arm spacing of the α-Al grains prominently was decreased when 0.05%–0.25% strontium was added. The decrease of the secondary dendrite arm spacing (SDAS) lead to the enhancement of the mechanical strength as well as the improvement of the thermal and electrical conductivity. When the Sr dosage was 0.15% in the commercial A356 alloy, the strength and the thermal conductivity of the A356 alloy simultaneously reached the maximum value. The improvement of the electrical and thermal conductivity might by contributed by the formation of a good conductor, Al2Si2Sr phase, on the Si surface. Further investigations suggested that the improvement of thermal conductivity was mainly due to the modification effect of Sr on the eutectic Si phase, which enlarged the specific area between the α-Al/eutectic Si interface. The WDS analysis indicated that the solubility of Si decreased in aluminum matrix by increasing in the Sr dosage. However, the excessive dosage of strontium would result in the coarsening of the modified silicon phase, deteriorating the strength and the thermal and electrical conductivity of the modified A356 alloys.

Graphic Abstract

In this work, the commercial A356 alloy was modified by adding small amounts of strontium (Sr). This kind of aluminum alloy with sound fluidity could be formed by using casting process, and it was potential to be applied in the structural parts. After the Sr modification, the plate-like silicon (Si) phase was transformed to fibrous shape in the raw commercial A356. Meanwhile, it was found that the content of silicon in the Al solid solution was reduced.The XRD and SEM analysis suggested that the Al2Si2Sr phase was formed on the modified silicon phase, which was favorable to the conduction of free electron.

Similar content being viewed by others

Data Availability

The datum used to support the findings of this study have been included in the submission files of Manuscript.doc, Figures.doc and Tables.doc. The datasets and programs used or analyzed during the current study are available from the corresponding author on reasonable request.

References

R.N. Lumley, I.J. Polmear, H. Groot, J. Ferrier, Thermal characteristics of heat-treated aluminum high-pressure die-castings. Scripta Mater. 58, 1006–1009 (2008)

M.C.S. Jr, A.R. Machado, W.F. Sales, M.A.S. Barrozo, E.O. Ezugwu, Machining of aluminum alloys: a review. Int. J. Adv. Manuf. Technol. 86, 1–14 (2016)

W.M. Doyle, Aluminum alloys: structure and properties. Metal Science, (1976)@@

J. Barcena, J. Maudes, M. Vellvehi, X. Jorda, I. Obieta, C. Guraya, L. Bilbao, C. Jiménez, C. Merveille, J.J.A.A. Coleto, Innovative packaging solution for power and thermal management of wide-bandgap semiconductor devices in space applications. Acta Astronaut 62, 422–430 (2008)

Z. Yang, X. Wang, J. Wu, The influence of silicon content on the thermal conductivity of Al–Si/diamond composites, in: International Conference on Electronic Packaging Technology & High Density Packaging (2009)

G.V. Voort, J.J.M. Asensio-Lozano, The Al–Si phase diagram. Microsc. Microanal. 15, 60–61 (2009)

N.D. Alexopoulos, M. Tiryakiogˇlu, A.N. Vasilakos, S.K. Kourkoulis, The effect of Cu, Ag, Sm and Sr additions on the statistical distributions of Si particles and tensile properties in A357–T6 alloy castings. Mater. Sci. Eng. A 604, 40–45 (2014)

A. Mazahery, M.O. Shabani, Modification mechanism and microstructural characteristics of eutectic Si in casting Al–Si alloys: a review on experimental and numerical studies. JOM 66, 726–738 (2014)

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, E. Pinatel, P.J. Uggowitzer, The effect of main alloying elements on the physical properties of Al–Si foundry alloys. Mater. Sci. Eng. A 560, 481–491 (2013)

F. Stadler, H. Antrekowitsch, W. Fragner, H. Kaufmann, P.J. Uggowitzer, The effect of nickel on the thermal conductivity of Al–Si cast alloys, in ICAA13 Pittsburgh, ed. by H. Weiland, A.D. Rollett, W.A. Cassada (Springer International Publishing, Cham, 2016), pp. 137–142

J.K. Chen, H.Y. Hung, C.F. Wang, N.K. Tang, Thermal and electrical conductivity in Al–Si/Cu/Fe/Mg binary and ternary Al alloys. J. Mater. Sci. 50, 5630–5639 (2015)

Y.M. Kim, S.W. Choi, S.K. Hong, The behavior of thermal diffusivity change according to the heat treatment in Al–Si binary system. J. Alloys Compds. 687, 54–58 (2016)

R. Landauer, J.J. Hall, Solid state physics. Science 160, 736–741 (2006)

X. Cui, H. Cui, Y. Wu, X. Liu, The improvement of electrical conductivity of hypoeutectic Al–Si alloys achieved by composite melt treatment. J. Alloys Compds. 788, 1322–1328 (2019)

S. Shabestari, S. Miresmaeili, S. Boutorabi, Effects of Sr-modification and melt cleanliness on melt hydrogen absorption of 319 aluminium alloy. J. Mater. Sci. 38, 1901–1907 (2003)

S.G. Shabestari, F. Shahri, Influence of modification, solidification conditions and heat treatment on the microstructure and mechanical properties of A356 aluminum alloy. J. Mater. Sci. 39, 2023–2032 (2004)

P. Rao, K. Das, B.S. Murty, M. Chakraborty, On the modification and segregation behavior of Sb in Al–7Si alloy during solidification. Mater. Lett. 62, 2013–2016 (2008)

W. Prukkanon, N. Srisukhumbowornchai, C. Limmaneevichitr, Influence of Sc modification on the fluidity of an A356 aluminum alloy. J. Alloys Compds. 487, 453–457 (2009)

M. Malekan, D. Dayani, A. Mir, Thermal analysis study on the simultaneous grain refinement and modification of 380.3 aluminum alloy. J. Therm. Anal. Calorim. 115, 393–399 (2014)

H. Qiu, H. Yan, Z. Hu, Modification of near-eutectic Al–Si alloys with rare earth element samarium. J. Mater. Res. 29, 1270–1277 (2014)

A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, New method of eutectic silicon modification in cast Al–Si alloys. Int. J. Metalcast. 11, 475–493 (2017)

J. Eiken, M. Apel, S.-M. Liang, R. Schmid-Fetzer, Impact of P and Sr on solidification sequence and morphology of hypoeutectic Al–Si alloys: combined thermodynamic computation and phase-field simulation. Acta Mater. 98, 152–163 (2015)

S. Farahany, A. Ourdjini, T.A.A. Bakar, M.H. Idris, A new approach to assess the effects of Sr and Bi interaction in ADC12 Al–Si die casting alloy. Thermochim. Acta 575, 179–187 (2014)

A. Knuutinen, K. Nogita, S.D. Mcdonald, A.K. Dahle, Modification of Al–Si alloys with Ba, Ca, Y and Yb. J. Light Met. 1, 229–240 (2001)

K. Wang, W. Li, J. Du, L. Yang, P. Tang, Thermal analysis of in-situ Al2O3/SiO2(p)/Al composites fabricated by stir casting process. Thermochim. Acta 641, 29–38 (2016)

H. Yamagata, W. Kasprzak, M. Aniolek, H. Kurita, J.H. Sokolowski, The effect of average cooling rates on the microstructure of the Al–20% Si high pressure die casting alloy used for monolithic cylinder blocks. J. Mater. Process. Technol. 203, 333–341 (2008)

K. Wang, P. Tang, Y. Huang, Y. Zhao, W. Li, J. Tian, Characterization of microstructures and tensile properties of recycled Al–Si–Cu–Fe–Mn alloys with individual and combined addition of titanium and cerium. Scanning 2018, 1–14 (2018)

S.W. Choi, H.S. Cho, S. Kumai, Effect of the precipitation of secondary phases on the thermal diffusivity and thermal conductivity of Al–4.5Cu alloy. J. Alloys Compds. 688, 897–902 (2016)

Z. Cong, D. Yong, S. Liu, S. Liu, W. Jie, B. Sundman, Microstructure and thermal conductivity of the as-cast and annealed Al–Cu–Mg–Si alloys in the temperature range from 25 °C to 400 °C). Int. J. Thermophys. 36, 2869–2880 (2015)

M. Emamy, H. Abdizadeh, H.R. Lashgari, A.A. Najimi, The effect of sr and grain refining elements on the microstructure and tensile properties of A356–10%B4C metal matrix composite. Mech. Adv. Mater. Struct. 18, 210–217 (2011)

A.M. Samuel, H.W. Doty, S. Valtierra, F.H.J.M. Samuel, Effect of grain refining and Sr-modification interactions on the impact toughness of Al–Si–Mg cast alloys. Mater. Des. 56, 264–273 (2014)

Y. Zhang, N. Ma, Y. Le, S. Li, H. Wang, Mechanical properties and damping capacity after grain refinement in A356 alloy. Mater. Lett. 59, 2174–2177 (2005)

Z. Zhang, X. Bian, Effect of Sr-modifying T reatment on hydrogen absorption of the melt and the shape of porosities. China Foundry 1, 5–8 (1999)

W. Lu, R. Wang, A study on the fading of Sr-modified Al–Si alloy. Special-cast and non-ferrous alloys, 1, 1–5 (1995)

R. Herman, An introduction to electrical resistivity in geophysics. Am. J. Phys. 69, 943 (2001)

M.H. Mulazimoglu, R.A.L. Drew, J.E. Gruzleski, The electrical conductivity of cast Al−Si alloys in the range 2 to 12.6 wt pct silicon. Metall. Trans. A 20, 383–389 (1989)

Y. Wang, R. Guan, D. Hou, Z. Yang, W. Jiang, H. Liu, The effects of eutectic silicon on grain refinement in an Al–Si alloy processed by accumulative continuous extrusion forming. J. Mater. Sci. 52, 1137–1148 (2017)

J. Barrirero, J. Li, M. Engstler, N. Ghafoor, P. Schumacher, M. Odén, F. Mücklich, Cluster formation at the Si/liquid interface in Sr and Na modified Al–Si alloys. Scripta Mater. 117, 16–19 (2016)

J. Manickaraj, A. Gorny, Z. Cai, S. Shankar, X-ray nano-diffraction study of Sr intermetallic phase during solidification of Al–Si hypoeutectic alloy. Appl. Phys. Lett. 104, 145 (2014)

A.M. Garay-Tapia, A.H. Romero, G. Trapaga, R. Arróyave, First-principles investigation of the Al–Si–Sr ternary system: ground state determination and mechanical properties. Intermetallics 21, 31–44 (2012)

P. Olafsson, R. Sandstrom, Å. Karlsson, Comparison of experimental, calculated and observed values for electrical and thermal conductivity of aluminium alloys. J. Mater. Sci. 32, 4383–4390 (1997)

W. Kurz, D.J. Fisher, Fundamentals of Solidification (Trans Tech Publications Ltd, Stafa-Zurich, 1998)

S. Miresmaeili, J. Campbell, S. Shabestari, S. Boutorabi, Precipitation of Sr-rich intermetallic particles and their influence on pore formation in Sr-modified A356 alloy. Metall. Mater. Trans. A 36, 2341–2349 (2005)

C. Su, D. Li, A.A. Luo et al., Effect of solute atoms and second phases on the thermal conductivity of Mg-RE alloys: a quantitative study. J. Alloys Compds. 747, 431–437 (2018)

Acknowledgements

This research has bee supported by the Research Start-up Funds of DGUT (GC300502-52); Development Project (Key) of Dongguan Social Science and Technology (Grant No. 20185071401604); and Special Scientific, Technological Innovation Project of Universities in Guangdong Province (2017KTSCX177); Natural Science Foundation of China (51701039); and Science and Technology Planning Project of Guangdong Province of China (2017A010103033). The authors would like to express our appreciation to Dr. Yang Xiaopeng and Mr. Liu Yu for their help in the WDS analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, K., Li, W., Xu, W. et al. Simultaneous Improvement of Thermal Conductivity and Strength for Commercial A356 Alloy Using Strontium Modification Process. Met. Mater. Int. 27, 4742–4756 (2021). https://doi.org/10.1007/s12540-020-00669-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00669-x