Abstract

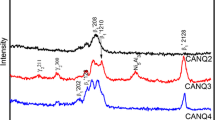

Effect of nano-CeO2 doping was studied on self-accommodating Cu–12Al–4Ni based shape memory alloys. Cu–Al–Ni based alloys are known for their high thermal stability and good shape memory properties but mechanical processing of these alloys is very difficult due to their high brittle nature and susceptibility to inter-granular failure. The present work deals with the enhancement of mechanical as well as shape recovery characteristics of these alloys with the addition of nano-CeO2. Significant improvements in ductility (1.8 times), strength and shape recovery were observed with the addition of nano-CeO2 with respect to the base alloy.

Graphic Abstract

Similar content being viewed by others

References

K. Bhattacharya, R.V. Kohn, Symmetry, texture and the recoverable strain of shape-memory polycrystals. Acta Mater. 44, 529–542 (1996)

S. Ozgen, C. Tatar, Thermoelastic transition kinetics of a gamma irradiated CuZnAl shape memory alloy. Met. Mater. Int. 18, 909–916 (2012)

P. Dalvand, S. Raygan, G.A. Lopez, M.B. Melendez, V.A. Chernenko, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00376-2

A. Pandey, A.K. Jain, S. Hussain, V. Sampath, R. Dasgupta, Effect of Nano CeO2 addition on the microstructure and properties of a Cu–Al–Ni shape memory alloy. Metall. Trans. B 47, 2205–2210 (2016)

S. Vajpai, R. Dube, S. Sangal, Application of rapid solidification powder metallurgy processing to prepare Cu–Al–Ni high temperature shape memory alloy strips with high strength and high ductility. Mater. Sci. Eng. A 570, 32–42 (2013)

S. Miyazaki, K. Otsuka, Development of shape memory alloys. ISIJ Int. 29, 353–377 (1989)

Z. Wei, H. Peng, D. Yang, C. Chung, J. Lai, Reverse transformations in CuAlNiMnTi alloy at elevated temperatures. Acta Mater. 44, 1189–1199 (1996)

X. Zhang, J. Sui, Q. Liu, W. Cai, Effects of Gd addition on the microstructure, mechanical properties and shape memory effect of polycrystalline Cu–Al–Ni shape memory alloy. Mater. Lett. 180, 223–227 (2016)

S.N. Saud, E. Hamzah, T. Abubakar, M. Zamri, M. Tanemura, Influence of Ti additions on the martensitic phase transformation and mechanical properties of Cu–Al–Ni shape memory alloys. J. Therm. Anal. Calorim. 118, 111–122 (2014)

S. Vajpai, R. Dube, S. Sangal, Microstructure and properties of Cu–Al–Ni shape memory alloy strips prepared via hot densification rolling of argon atomized powder preforms. Mater. Sci. Eng. A 529, 378–387 (2011)

M. Morris, High temperature properties of ductile Cu–Al–Ni shape memory alloys with boron additions. Acta Metall. Mater. 40, 1573–1586 (1992)

D. Roh, J. Kim, T. Cho, Y.-G. Kim, Tensile properties and microstructure of microalloyed Cu–Al–Ni–X shape memory alloys. Mater. Sci. Eng. A 136, 17–23 (1991)

G. Sure, L. Brown, The mechanical properties of grain refined β-CuAlNi strain-memory alloys. Metall. Mater. Trans. A 15, 1613–1621 (1984)

J. Lee, C. Wayman, Grain refinement of a Cu–Al–Ni shape memory alloy by Ti and Zr additions. Trans. Jpn. Inst. Met. 27, 584–591 (1986)

Y. Wang, Z. Wang, Y. Yang, W. Chen, The effects of CeO2 on the mechanical properties and thermal shock resistance of thermal sprayed NiAl intermetallic coatings. Intermetallics 16, 682–688 (2008)

Y. Liu, in IUTAM symposium on mechanics of martensitic phase transformation in solids, ed. by Q.P. Sun (Springer, Netherlands, 2002), p. 37

Y. Ma, C. Jiang, Y. Li, H. Xu, C. Wang, X. Liu, Study of Ni50 + xMn25Ga25 − x (x = 2–11) as high-temperature shape-memory alloys. Acta Mater. 55, 1533–1541 (2007)

Acknowledgements

The authors express their gratitude to Director, CSIR-AMPRI for extending laboratory facilities to carry out the work. One of the authors expresses his thankfulness to AcSIR-AMPRI, Bhopal, India for funding the scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hussain, S., Pandey, A. & Dasgupta, R. Nano-CeO2 Doped Cu–Al–Ni SMAs with Enhanced Mechanical as well as Shape Recovery Characteristics. Met. Mater. Int. 27, 1478–1482 (2021). https://doi.org/10.1007/s12540-019-00570-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00570-2