Abstract

The key requirement to consolidate high-energy mechanically alloyed nanocrystalline powders is to achieve densification and particle bonding without impairment in the mechanical properties. Recent demonstrations of consolidation methods involving high shear, pressure and temperature have shown promising results for bonding high strength particulate materials produced by mechanical alloying. In this study, we report the ability of multi-pass high temperature equal channel angular extrusion to produce bulk ferritic alloys from nanocrystalline Fe–Ni–Zr powders. Subsequent microstructural characterizations indicate limited grain growth as the average grain sizes remain smaller than 100 nm after processing temperatures of 600 °C and 700 °C, above which grains reach micron sizes. The compression test results reveal that the alloys exhibit high mechanical strength at room and moderately high temperatures compared to the pure Fe and Fe–Ni alloys without Zr addition.

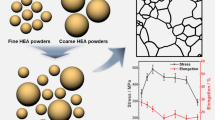

Graphic Abstract

Similar content being viewed by others

References

E.O. Hall, Nature 173, 948–949 (1954)

R. Valiev, Nat. Mater. 3, 511–516 (2004)

H. Gleiter, Adv. Mater. 4, 474–481 (1992)

C.C. Koch, Scr. Mater. 49, 657–662 (2003)

C. Suryanarayana, Adv. Eng. Mater. 7, 983–992 (2005)

H. Gleiter, Acta Mater. 48, 1–29 (2000)

H. Kotan, M. Saber, C.C. Koch, R.O. Scattergood, Mater. Sci. Eng. A 552, 310–315 (2012)

C.C. Koch, J. Mater. Sci. 42, 1403–1414 (2007)

P.C. Millett, R.P. Selvam, A. Saxena, Acta Mater. 55, 2329–2336 (2007)

J.R. Trelewicz, C.A. Schuh, Phys. Rev. B 79, 094112 (2009)

W.T. Xing, A.R. Kalidindi, D. Amram, C.A. Schuh, Acta Mater. 161, 285–294 (2018)

T. Chookajorn, H.A. Murdoch, C.A. Schuh, Science 337, 951–954 (2012)

H. Kotan, Mater. Sci. Eng. A 647, 136–143 (2015)

H. Kotan, K.A. Darling, R.O. Scattergood, C.C. Koch, J. Alloy. Compd. 615, 1013–1018 (2014)

H. Kotan, K.A. Darling, Mater. Sci. Eng. A 686, 168–175 (2017)

Z.B. Jiao, C.A. Schuh, Acta Mater. 161, 194–206 (2018)

B.G. Clark, K. Hattar, M.T. Marshall, T. Chookajorn, B.L. Boyce, C.A. Schuh, JOM 68, 1625–1633 (2016)

B. Schuh, F. Mendez-Martin, B. Volker, E.P. George, H. Clemens, R. Pippan et al., Acta Mater. 96, 258–268 (2015)

M. Saber, H. Kotan, C.C. Koch, R.O. Scattergood, Mater. Sci. Eng. A 556, 664–670 (2012)

H. Kotan, K.A. Darling, M. Saber, C.C. Koch, R.O. Scattergood, J. Alloy. Compd. 551, 621–629 (2013)

K.A. Darling, R.N. Chan, P.Z. Wong, J.E. Semones, R.O. Scattergood, C.C. Koch, Scr. Mater. 59, 530–533 (2008)

H. Kotan, K.A. Darling, M. Saber, R.O. Scattergood, C.C. Koch, J. Mater. Sci. 48, 8402–8411 (2013)

N. Anento, A. Serra, Y. Osetsky, Acta Mater. 132, 367–373 (2017)

K.A. Darling, M. Kapoor, H. Kotan, B.C. Hornbuckle, S.D. Walck, G.B. Thompson et al., J. Nucl. Mater. 467, 205–213 (2015)

H. Kotan, K.A. Darling, J. Mater. Eng. Perform. 24, 3271–3276 (2015)

D.J. Barton, C. Kale, B.C. Hornbuckle, K.A. Darling, K.N. Solanki, G.B. Thompson, Mater. Sci. Eng. A 725, 503–509 (2018)

Y.J. Hu, J. Li, K.A. Darling, W.Y. Wang, B.K. VanLeeuwen, X.L. Liu et al., Sci. Rep. 5, 11772 (2015)

H. Kotan, K.A. Darling, M. Saber, R.O. Scattergood, C.C. Koch, J. Mater. Sci. 48, 2251–2257 (2013)

C.C. Koch, R.O. Scattergood, K.M. Youssef, E.H. Chan, Y.T.T. Zhu, J. Mater. Sci. 45, 4725–4732 (2010)

R.Z. Valiev, T.G. Langdon, Prog. Mater. Sci. 51, 881–981 (2006)

I. Karaman, M. Haouaoui, H.J. Maier, J. Mater. Sci. 42, 1561–1576 (2007)

Z.H.M. Furukawa, M. Nemoto, T.G. Langdon, J. Mater. Sci. 36, 2835 (2001)

V.M. Segal, Mater. Sci. Eng. A A197, 157–164 (1995)

M.W. Phaneuf, Micron 30, 277–288 (1999)

Y.Z. Chen, K. Wang, G.B. Shan, A.V. Ceguerra, L.K. Huang, H. Dong et al., Acta Mater. 158, 340–353 (2018)

J. Humphreys, G.S. Rohrer, A. in Rollett, Recrystallization and Related Annealing Phenomena, 3rd edn, pp. 1–704 (2017)

A. Baldan, J. Mater. Sci. 37, 2171–2202 (2002)

S.G. Chowdhury, C. Xu, T.G. Langdon, Mater. Sci. Eng. A 473, 219–225 (2008)

S. Suwas, S. Biswas, S. Singh, K. Chattopadhyay, in Nanomaterials by Severe Plastic Deformation IV, Pts 1 and 2, vol. 584–586, pp. 585–590 (2008)

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill, New York, 1961)

J.I. Langford, A.J.C. Wilson, J. Appl. Crystallogr. 11, 102–113 (1978)

T.R. Malow, C.C. Koch, Metall. Mater. Trans. A 29, 2285–2295 (1998)

T.D. Shen, R.B. Schwarz, S. Feng, J.G. Swadener, J.Y. Huang, M. Tang, H. Zhang, S.C. Vogel, Y.S. Zhao, Acta Mater. 55, 5007–5013 (2007)

S. Xu, Z.J. Zhou, F. Long, H.D. Jia, N. Guo, Z.W. Yao et al., Mater. Sci. Eng. A 739, 45–52 (2019)

Acknowledgements

H. Kotan gratefully acknowledges support from Necmettin Erbakan University through the BAP under Grant Number of 171219006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kotan, H., Darling, K.A. & Luckenbaugh, T. High Temperature Mechanical Properties and Microstructures of Thermally Stabilized Fe-Based Alloys Synthesized by Mechanical Alloying Followed by Hot Extrusion. Met. Mater. Int. 27, 1790–1797 (2021). https://doi.org/10.1007/s12540-019-00567-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00567-x