Abstract

In order to reveal the formation mechanism of microstructural delamination in flange steel during punching, the microstructural characteristics of flange steels with 0.064, 0.085, and 0.101 wt% carbon contents were analyzed by an optical microscope, optical emission spectrometer, metal in situ analyzer, and electron probe microanalyzer. It was found that microstructural delamination occurred due to C and Mn segregation, especially the former. The intensive segregation degree of C was dependent on its relatively smaller partition coefficient. Moreover, the segregation degree gradually decreased with the decreasing carbon content. And the increased segregations of elements except carbon were related to the coupling effect between different alloying elements. Furthermore, C and Mn were prone to segregate at the 1/4th position along the transverse direction of the casting slab; hence, almost no segregation was noticed at the edge of the casting slab. The homogenization treatment had a substantial effect on the elimination of C segregation; however, Mn segregation was relatively hard to be removed.

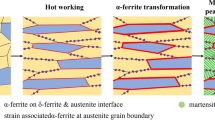

Graphic Abstract

Similar content being viewed by others

References

R.J. Zhang, L.H. Lang, R. Zafar et al., Trans. Nonferrous Met. Soc. China 9, 2442 (2016)

S.S.M. Tavares, J.M. Pardal, B.B. Almeida, Eng. Fail. Anal. 84, 1 (2018)

J.Q. Qian, Y. Yue, J. Iron. Steel Res. Int. 12, 1124 (2014)

H.M. Shalaby, Eng. Fail. Anal. 80, 290 (2017)

A.M. Yousefi, J.B.P. Lim, G.C. Clifton, Constr. Build. Mater. 191, 713 (2018)

X.Y. Yang, L.H. Lang, K.N. Liu et al., Trans. Nonferrous Met. Soc. China 25, 3389 (2015)

R.A. Bartlett, S.R. Frost, P. Bowen, Int. J. Press. Vessel Pip. 3, 263 (1991)

J.L. Otegui, P.G. Fazzini, A. Márquez, Eng. Fail. Anal. 6, 1825 (2009)

S. Rahman, Int. J. Fatigue 113, 69 (2018)

P. Yasniy, S. Glado, V. Iasnii, Procedia Struct. Integr. 2, 3280 (2016)

Q.Q. Yu, Y.F. Wu, Constr. Build. Mater. 155, 1188 (2017)

G. Avramovic-Cingara, Y. Ososkov, M.K. Jain et al., Mater. Sci. Eng. A 7, 516 (2009)

H. Ghadbeigi, C. Pinna, S. Celotto et al., Mater. Sci. Eng. A 527, 5026 (2010)

C. Zhao, H.T. Jiang, D. Tang et al., Mat. Heat Treat. 20, 17 (2008). (in Chinese)

M.S. Mustapa, Y. Mutoh, Mater. Sci. Eng. A 527, 2592 (2010)

L. Ma, J.Y. Liu, C. Li et al., Mater. Charact. 153, 294 (2019)

A. Karani, S. Koley, M. Shome, Eng. Fail. Anal. 96, 289 (2019)

X.L. Gan, Q. Yuan, G. Zhao et al., Steel Res. Int. (2019). https://doi.org/10.1002/srin.201900040

Q. Yuan, G. Xu, M. Liu et al., Steel Res. Int. (2018). https://doi.org/10.1002/srin.201800318

R. Ma, Z.B. Dong, Y.H. Wei et al., Cryst. Res. Technol. 44, 1197 (2009)

Z.W. Huang, Scr. Mater. 52, 1021 (2005)

D. Dye, L. Thuinet, M. Ganesan, Metall. Mater. Trans. B 38, 557 (2007)

Z. Jing, Y. Li, Y. Wang et al., Mater. Rep. 1, 309 (2019)

J.S. Zuback, P. Moradifar, Z. Khayat et al., J. Alloys Compd. 798, 446 (2019)

K.K. Cai, Quality Control of Continuous Casting Billet (Metallurgical Industry Press, Beijing, 2010)

Y. Liu, X.H. Wang, K.J. Zhang et al., Int. J. Miner. Metall. Mater. 29, 896 (2007)

Z.D. Li, G. Miyamoto, Z.G. Yang et al., Acta Metall. Sin. 9, 1066 (2010)

J.X. Chen, Common Chart Data Manual for Steel Making (Metallurgical Industry Press, Beijing, 1984)

X.G. Zeng, J. Univ. Sci. Technol. Beijing 31, 145 (2009)

M. Takashi, Z. Masafumi, Tstsu-to-Hagané 3, 17 (2013). (in Japanese)

Y.D. Jiang, Z.L. Xue, J. Wu et al., J. Univ. Sci. Technol. Wuhan 4, 258 (2010)

F.Y. Zhu, H.J. Duan, L.F. Zhang et al., Shanghai Met. 5, 39 (2014). (in Chinese)

Acknowledgements

The authors gratefully acknowledge the financial supports from the financial supports from Post-doctoral Innovative Research Post of Hubei Province, the National Natural Science Foundation of China (NSFC) (Nos. 51874216 and 51704217), the Major Projects of Technology Innovation of Hubei Province (2017AAA116) and Hebei Joint Research Fund for Iron and Steel (E2018318013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, W., Yuan, Q., Liu, S. et al. Investigation on Microstructural Delamination and Compositional Segregation in Flange Steel with a High Stretch Ratio. Met. Mater. Int. 27, 1587–1598 (2021). https://doi.org/10.1007/s12540-019-00551-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00551-5