Abstract

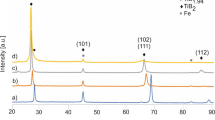

Al 7075 alloy matrix reinforced with different weight percentage of titanium borides (TiB2, 0, 1.5, 3, 4.5 and 6 wt%) and 1 wt% graphite (Gr) hybrid composites were synthesized by in-situ liquid metallurgy route, then the sliding wear characteristics were performed and investigated in this research work. TiB2 reinforced as 0, 1.5, 3, 4.5 and 6 wt% by the in situ chemical reaction of KBF4 and K2TiF6 salts and 1 wt% Gr with the Al 7075 matrix were added constantly in the melt. Several experiments were carried out to examine the wear behavior of the fabricated composite specimens through a tribometer at ambient temperature. The weight percentage of reinforcement (TiB2 particles), the applied load, the sliding velocity (SV), and the sliding distance (SD) were selected as process parameters at five different levels. The response surface methodology (RSM) was used to conduct the experiments as RSM is the feasible and accurate method employed for optimizing to set the parameters. To check the significance of the developed model by RSM, ANOVA and confirmatory tests were also accomplished. FESEM surface morphology was also carried out to illustrate the uniform dispersion of the TiB2–Gr particulates in Al 7075 matrix. The predicted wear characteristics from the developed model were well agreed with the experimental results. The obtained results were explained that both the increase in the percentage of RF and SV have dropped the wear loss (WL) curve whereas the load at all SVs and the SDs were uplifted the WL. The worn surface morphology explained that the adhesive mechanisms were dominated during the sliding wear test. Further, severe and mild wear occurred during higher load and lower load respectively.

Graphic Abstract

Similar content being viewed by others

Data Availability Statement

The experimental datasets obtained from this research work and then the analyzed results during the current study are available from the corresponding author on reasonable request.

Abbreviations

- RSM:

-

Response surface methodology

- ANOVA:

-

Analysis of variance

- FESEM:

-

Field emission scanning electron microscope

- RF:

-

Reinforcement

- AL:

-

Applied load

- SV:

-

Sliding velocity

- SD:

-

Sliding distance

- WL:

-

Wear lose

- MMCs:

-

Metal matrix composites

- AMCs:

-

Aluminium matrix composites

- TiB2 :

-

Titanium boride

- DSWB:

-

Dry sliding wear behavior

- DOE:

-

Design and analysis of experiments

- CCD:

-

Central composite design

- Gr:

-

Graphite

- XRD:

-

X-ray diffraction

- TEM:

-

Transmission electron microscope

- EBSD:

-

Electron backscattered diffraction

- WEDM:

-

Wire-cut electric discharge machine

- WR:

-

Wear rate

References

S. Natarajan, R. Narayanasamy, S.P.K. Babu, G. Dinesh, B.A. Kumar, K. Sivaprasad, Mater. Des. 30, 2521 (2009)

H. Li, X. Wang, L. Chai, H. Wang, Z. Chen, Z. Xiang, T. Jin, Mater. Sci. Eng. A 720, 60 (2018)

H. Yi, N. Ma, X. Li, Y. Zhang, H. Wang, Mater. Sci. Eng. A 419, 12 (2006)

T. Tayeh, J. Douin, S. Jouannigot, M. Zakhour, M. Nakhl, J.-F. Silvain, J.-L. Bobet, Mater. Sci. Eng. A 591, 1 (2014)

A. Baradeswaran, A.E. Perumal, Compos. Part B Eng. 56, 464 (2014)

R.N. Rai, G.L. Datta, M. Chakraborty, A.B. Chattopadhyay, Mater. Sci. Eng. A 428, 34 (2006)

G.N. Kumar, R. Narayanasamy, S. Natarajan, S.P.K. Babu, K. Sivaprasad, S. Sivasankaran, Mater. Des. 31, 1526 (2010)

R.N. Rao, S. Das, Mater. Des. 31, 1200 (2010)

A.M. Al-Qutub, I.M. Allam, M.A.A. Samad, J. Mater. Sci. 43, 5797 (2008)

F. Tang, X. Wu, S. Ge, J. Ye, H. Zhu, M. Hagiwara, J.M. Schoenung, Wear 264, 555 (2008)

K.R. Ramkumar, H. Bekele, S. Sivasankaran, Experimental investigation on mechanical and turning behavior of al 7075/x% wt. TiB2-1% Gr in situ hybrid composite. Adv. Mater. Sci. Eng. (2015). https://doi.org/10.1155/2015/727141

D. Chen, C. Zou, Y. J. Zhang, N. H. Ma, H. W. Wang, Tensile properties of 15wt.% TiB2/7055 composite fabricated by in situ method. Advanced Materials Research (Trans Tech Publ, 2014), pp. 165–169.

L.M. Tham, M. Gupta, L. Cheng, Acta Mater. 49, 3243 (2001)

S. Kumar, M. Chakraborty, V.S. Sarma, B.S. Murty, Wear 265, 134 (2008)

S.B.V. Siva, R.I. Ganguly, G. Srinivasarao, K.L. Sahoo, Mater. Manuf. Process. 28, 1082 (2013)

P. Senthil, T. Selvaraj, K. Sivaprasad, Int. J. Adv. Manuf. Technol. 67, 1589 (2013)

D.C. Montgomery, Design and Analysis of Experiments, 4th edn. (Wiley, New York, 1997)

V. Vembu, G. Ganesan, Def. Technol. 11, 390 (2015)

H. Joardar, N.S. Das, G. Sutradhar, S. Singh, Measurement 47, 452 (2014)

P. Sharma, D. Khanduja, S. Sharma, J. Mater. Res. Technol. 5, 29 (2016)

A. Baradeswaran, A.E. Perumal, Compos. Part B Eng. 56, 472 (2014)

S. Basavarajappa, G. Chandramohan, K. Mukund, M. Ashwin, M. Prabu, J. Mater. Eng. Perform. 15, 668 (2006)

A. Zeren, Ind. Lubr. Tribol. 67, 262 (2015)

S. Mahdavi, F. Akhlaghi, Tribol. Lett. 44, 1 (2011)

J. Singh, Friction 4, 191 (2016)

L. Jinfeng, J. Longtao, W. Gaohui, T. Shoufu, C. Guoqin, Rare Met. Mater. Eng. 38, 1894 (2009)

S. Sivasankaran, A.I.M.S. Mater, Sci. 6, 80 (2019)

M. E. Turan, H. Zengin, and Y. Sun, Dry sliding wear behavior of (MWCNT+GNPs) reinforced AZ91 magnesium matrix hybrid composites. Metals Mater. Int. (In press). https://doi.org/10.1007/s12540-019-00338-8

Acknowledgements

The authors acknowledge the financial support of Qassim University under Deanship Research Grant of Saudi Arabia (Grant No: 2343-qec-2018-1-14-s) and provided research facilities to carry out this research work.

Author information

Authors and Affiliations

Contributions

SS and FA have put the idea of this work, conceived and designed the experiments; SS and KRR have carried out the experimental part and investigated the results; SS has written the article; FA and OMI have edited the article and supported some research facilities.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sivasankaran, S., Ramkumar, K.R., Al-Mufadi, F.A. et al. Effect of TiB2/Gr Hybrid Reinforcements in Al 7075 Matrix on Sliding Wear Behavior Analyzed by Response Surface Methodology. Met. Mater. Int. 27, 1739–1755 (2021). https://doi.org/10.1007/s12540-019-00543-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00543-5