Abstract

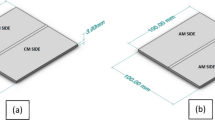

Dual laser-beam bilateral synchronous welding is introduced to produce the 2.5 mm thick 5A90 Al–Li alloy T-joint. The grain morphology and grain size of weld metal (WM) in the T-joint are analyzed and calculated. The tensile experiment, scanning electron microscopy and energy disperse spectroscopy are respectively employed to study the tensile strength, fracture morphology and chemical composition of the T-joint. The results reveal that when the laser power is increased from 2500 to 3000 W, the grain sizes of fine-grained layers and columnar dendrites near the fusion line are significantly reduced. Conversely, that of equiaxed dendrites at the WM center is not sensitive to the variety of laser power. Moreover, the degree of elemental segregation in WM near the fusion line is also aggravated with the increasing of the laser power. The tensile strength of the T-joint with the laser power of 2500 W is significantly higher than that with the laser power of 3000 W. The tensile fracture locations are occurred in the weld toe with obvious pores, shear dimples and tear ridges, which are the typical characteristics of ductile fracture. Besides, the chemical compositions of the second phase particles in the WM are more sensitive to than the variation of laser power compared with that of the matrix.

Graphic Abstract

Similar content being viewed by others

References

A. Kostrivas, J.C. Lippold, Weldability of Li-bearing aluminium alloys. Int. Mater. Rev. 44(6), 217–237 (1999)

P. Chai, Y. Wang, Effect of rotational speed on microstructure and mechanical properties of 2060 aluminum alloy RFSSW joint. Met. Mater. Int. 25(6), 1–12 (2019)

E. Schubert, M. Klassen, I. Zerner, C. Walz, G. Sepold, Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry. J. Mater. Process. Technol. 115(1), 2–8 (2001)

M. Pacchione, J. Telgkamp, Challenges of the metallic fuselage, in Proceedings of the 25th International Congress of the Aeronautical Sciences-ICAS, Hamburg, Germany, September (2006)

L. Li, G. Peng, J. Wang, J. Gong, S. Meng, Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminum alloys under subatmospheric pressures. Int. J. Heat. Mass. Transf. 133, 812–826 (2019)

W. Tao, Z. Yang, Y. Chen, L. Li, Z. Jiang, Y. Zhang, Double-sided fiber laser beam welding process of T-joints for aluminum aircraft fuselage panels: filler wire melting behavior, process stability, and their effects on porosity defects. Opt. Laser Technol. 52, 1–9 (2013)

D. Dittrich, J. Standfuss, J. Liebscher, B. Brenner, E. Beyer, Laser beam welding of hard to weld Al alloys for a regional aircraft fuselage design–first results. Phys. Procedia 12, 113–122 (2011)

D. Narsimhachary, R.N. Bathe, G. Padmanabham, A. Basu, Influence of temperature profile during laser welding of aluminum alloy 6061 T6 on microstructure and mechanical properties. Mater. Manuf. Process. 29(8), 948–953 (2014)

E. Cicală, G. Duffet, H. Andrzejewski, D. Grevey, S. Ignat, Hot cracking in Al–Mg–Si alloy laser welding–operating parameters and their effects. Mater. Sci. Eng. A. 395(1–2), 1–9 (2005)

M. Sheikhi, F.M. Ghaini, H. Assadi, Prediction of solidification cracking in pulsed laser welding of 2024 aluminum alloy. Acta Mater. 82, 491–502 (2015)

C. Liu, D.O. Northwood, S.D. Bhole, Tensile fracture behavior in CO2 laser beam welds of 7075-T6 aluminum alloy. Mater. Des. 25(7), 573–577 (2004)

X. Zhang, W. Yang, R. Xiao, Microstructure and mechanical properties of laser beam welded Al–Li alloy 2060 with Al–Mg filler wire. Mater. Des. 88, 446–450 (2015)

X. Zhang, T. Huang, W. Yang, R. Xiao, Z. Liu, L. Li, Microstructure and mechanical properties of laser beam-welded AA2060 Al-Li alloy. J. Mater. Process. Technol. 237, 301–308 (2016)

Y. Huang, G. Li, W. Shao, S. Gong, X. Zhang, A novel dual-channel weld seam tracking system for aircraft T-joint welds. Int. J. Adv. Manuf. Technol. 91(1–4), 751–761 (2017)

S. Janasekaran, M.F. Jamaludin, M.R. Muhamad, F. Yusof, M.H.A. Shukor, Autogenous double-sided T-joint welding on aluminum alloys using low power fiber laser. Int. J. Adv. Manuf. Technol. 90(9–12), 3497–3505 (2017)

Z.B. Yang, W. Tao, Q.L. Li, Y.B. Chen, F.Z. Li, Y.L. Zhang, Double-sided laser beam welded T-joints for aluminum aircraft fuselage panels: process, microstructure, and mechanical properties. Mater. Des. 33, 652–658 (2012)

J. Enz, S. Riekehr, V. Ventzke, N. Kashaev, Influence of the local chemical composition on the mechanical properties of laser beam welded Al-Li alloys. Phys. Procedia 39, 51–58 (2012)

B. Han, Y. Chen, W. Tao, H. Li, L. Li, Microstructural evolution and interfacial crack corrosion behavior of double-sided laser beam welded 2060/2099 Al–Li alloys T-joints. Mater. Design. 135, 353–365 (2017)

H. Yu, X. Zhan, Y. Kang, P. Xia, X. Feng, Numerical simulation optimization for laser welding parameter of 5A90 Al–Li alloy and its experiment verification. J. Adhes. Sci. Technol. 33(2), 137–155 (2019)

S. Datta, M.S. Raza, P. Saha, D.K. Pratihar, Effects of process parameters on the quality aspects of weld-bead in laser welding of NiTinol sheets. Mater. Manuf. Process. 34(6), 648–659 (2019)

X.B. Zhao, Measurement and calculation of three-dimensional grain sizes and size distribution functions. Microsc. Microanal. 4(4), 420–427 (1998)

X. Zhan, C. Qi, J. Zhou, L. Liu, D. Gu, Effect of heat input on the subgrains of laser melting deposited Invar alloy. Opt. Laser Technol. 109, 577–583 (2019)

J. Yue, X. Dong, R. Guo, W. Liu, L. Li, Numerical simulation of equivalent heat source temperature field of asymmetrical fillet root welds. Int. J. Heat. Mass. Tran. 130, 42–49 (2019)

S. Kou, Welding Metallurgy (Wiley, Hoboken, 2003)

Acknowledgements

The authors gratefully acknowledge the financial support of the project from the National Natural Science Foundation of China (U1637103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, S., Zhan, X., Zhao, Y. et al. Influence of Laser Power on Grain Size and Tensile Strength of 5A90 Al–Li Alloy T-joint Fabricated by Dual Laser-Beam Bilateral Synchronous Welding. Met. Mater. Int. 27, 1671–1685 (2021). https://doi.org/10.1007/s12540-019-00538-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00538-2