Abstract

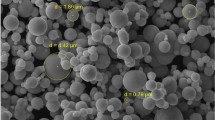

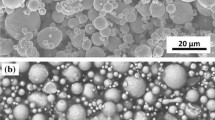

In this study, rheological and thermal decomposition behavior of AISI 4605 MIM feedstock investigated using capillary and thermogravimetric analysis. For this purpose and in order to find the critical solids loading, the feedstock was prepared by compounding AISI 4605 micro powder (~ 4 µm) with an adopted multi-component wax-based binder system at various powder loadings (53–61 vol%). After preparing the feedstock with optimal solids loading, fundamental rheological characteristics of homogenized feedstock, including flow behavior index (n), flow activation energy (E), and general moldability index (αstv) were studied. Furthermore, thermal analysis of feedstock, including apparent debinding activation energy and master decomposition curve was investigated. The results showed that critical solids loading of feedstock is around 58 vol%. The flow behavior index of developed feedstock was acceptable, since it came out to be less than one. Also, flow activation energy which shows the sensitivity of material to temperature changes, came out to be 70.406 kJ/mol. Using these two parameters, general moldability index was calculated to be 2.3147E−06. Finally, the master decomposition curve of feedstock was constructed based on calculated apparent debinding activation energy and verified using decomposition curves at different heating rates of 2, 5 and 10 °C/min.

Graphic Abstract

Similar content being viewed by others

References

R.M. German, A. Bose, Injection Molding of Metals and Ceramics (Princeton, Metal Powder Industries Federation, 1997), pp. 11–53

R.M. German, Powder Metallurgy Science (Princeton, Metal Powder Industries Federation, 1994), pp. 6692–8540

Y.L. Ho, S.T. Lin, Metall. Mater. Trans. A 26, 133 (1995)

A.J. Coleman, K. Murray, M. Kearns, T.A. Tingskog, Processing and properties of 4605 MIM parts manufactured via a master alloy route (The European Powder Metallurgy Association, 2012). https://www.materials.sandvik/globalassets/global/downloads/products_downloads/metal_powders/technical_papers/processing-and-properties-of-mim-aisi-4605-via-master-alloy-routes.pdf. Accessed 13 Mar 2012

S.V. Atre, T.J. Weaver, R.M. German, Injection Molding of Metals and Ceramics (Princeton, Metal Powder Industries Federation, 1998)

W.J. Tseng, Mater. Sci. Eng. A 289, 116 (2000)

M.D. Hayat, G. Wen, M.F. Zulkifli, P. Cao, Powder Technol 270, 296 (2015)

K.C. Hsu, G.M. Lo, Powder Metall. 39, 286 (1996)

K.C. Hsu, C.C. Lin, G.M. Lo, Can. Metall. Q. 35, 181 (1996)

G. Aggarwal, S.J. Park, I. Smid, Int. J. Refract. Met. Hard Mater. 24, 253 (2006)

J.P. Choi, H.G. Lyu, W.S. Lee, J.S. Lee, Powder Technol. 261, 201 (2014)

M.H.I. Ibrahim, N. Muhamad, A.B. Sulong, Int. J. Mech. Mater. Eng. 4, 1 (2009)

J. Hidalgo, A. Jiménez-Morales, J.M. Torralba, J. Eur. Ceram. Soc. 32, 4063 (2012)

V.A. Krauss, E.N. Pires, A.N. Klein, M.C. Fredel, Mater. Res. 8, 187 (2005)

J.W. Oh, W.S. Lee, S.J. Park, Powder Technol. 311, 18 (2017)

Y. Li, L. Li, K.A. Khalil, J. Mater. Process. Technol. 183, 432 (2007)

Y. Li, X. Liu, F. Luo, J. Yue, Trans. Nonferrous Met. Soc. China 17, 1 (2007)

S. Md Ani, A. Muchtar, N. Muhamad, J.A. Ghani, Ceram. Int. 40, 2819 (2014)

D. Tsai, AIChE J. 37, 547 (1991)

P. Calvert, M. Cima, J. Am. Ceram. Soc. 73, 575 (1990)

Y.C. Lam, S.C.M. Yu, K.C. Tam, Y. Shengjie, Metall. Mater. Trans. A. 31, 2597 (2000)

M.R. Barone, J.C. Ulicny, J. Am. Ceram. Soc. 73, 3323 (1990)

S.A. Matar, M.J. Edirisinghe, J.R.G. Evans, E.H. Twizell, J. Mater. Res. 8, 617 (1993)

S.J. Park, R.M. German, Int. J. Mater. Struct. Integr. 1, 128 (2007)

J.H. Song, J.R.G. Evans, M.J. Edirisinghe, E.H. Twizell, J. Mater. Res. 15, 449 (2000)

S.-J. Park, Y. Wu, D.F. Heaney, X. Zou, G. Gai, R.M. German, Metall. Mater. Trans. A. 40, 215 (2009)

G. Aggarwal, I. Smid, S.J. Park, R.M. German, Int. J. Refract. Met. Hard Mater. 25, 226 (2007)

S.V. Atre, R.K. Enneti, S.J. Park, R.M. German, Powder Metall. 51, 368 (2008)

J.W. Oh, W.S. Lee, S.J. Park, Int. J. Adv. Manuf. Technol. 97, 4115 (2018)

J. Man, J. Sae, C. Woo, J. Won, J. Hyun, K.H. Kate, S.V. Atre, Y. Kim, S. Jin, Ceram. Int. 44, 12709 (2018)

D. Seul, J. Won, H. Jun, S. Jin, J. Alloys Compd. 749, 758 (2018)

R.H. Christopher, S. Middleman, Ind. Eng. Chem. Fundam. 4, 422 (1965)

S. Gabbanelli, G. Drazer, J. Koplik, Phys. Rev. E. 72, 46312 (2005)

X. Huang, B. Liang, S. Qu, J. Mater. Process. Technol. 137(1–3), 132 (2003)

R.P. Chhabra, J.F. Richardson, Non-Newtonian Flow and Applied Rheology: Engineering Applications (Butterworth-Heinemann, Oxford, 2011)

M.Y. Cao, B.O. Rhee, C.I. Chung, Adv. Powder Metall. 2, 59 (1991)

S.-L. Li, Y.-M. Li, X.-H. Qu, B.-Y. Huang, Trans. Nonferrous Met. Soc. China. 12, 105 (2002)

H.E. Kissinger, Anal. Chem. 29, 1702 (1957)

G. Aggarwal, S.-J. Park, I. Smid, R.M. German, Metall. Mater. Trans. A. 38, 606 (2007)

D.M. Bigg, R.G. Barry, Progress in 56th Society of Plastic Engineers–Annual Technical Conference (1998).

M. Khakbiz, A. Simchi, R. Bagheri, Mater. Sci. Eng. A. 407, 105 (2005)

M.E. Sotomayor, A. Várez, B. Levenfeld, Powder Technol. 200, 30 (2010)

J.M. Park, J.S. Han, C.W. Gal, J.W. Oh, K.H. Kate, S.V. Atre, Y. Kim, S.J. Park, Powder Technol. 330, 19 (2018)

J.W. Oh, Y. Seong, S.J. Park, J. Mater. Process. Technol. 262, 503 (2018)

J.W. Oh, J.M. Park, D.S. Shin, J. Noh, S.J. Park, Mater. Manuf. Process., 1 (2018).

R.E. Smallman, R.J. Bishop, Modern physical metallurgy and materials engineering, (Elsevier, UK, 1999), pp. 35–278

H. Abolhasani, N. Muhamad, Int. J. Mech. Mater. Eng. 4, 294 (2009)

Z.Y. Liu, N.H. Loh, S.B. Tor, K.A. Khor, Y. Murakoshi, R. Maeda, Mater. Lett. 48, 31 (2001)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Askari, A., Alaei, M.H., Mehdipoor Omrani, A. et al. Rheological and Thermal Characterization of AISI 4605 Low-Alloy Steel Feedstock for Metal Injection Molding Process. Met. Mater. Int. 26, 1820–1829 (2020). https://doi.org/10.1007/s12540-019-00442-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00442-9