Abstract

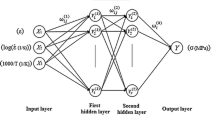

The intermediate-temperature (473–973 K) deformation behavior of a nickel-based superalloy is researched by uniaxial tensile experiments. It is observed that the flow characteristics and the Portevin–Le Chatelier (PLC) effects are significantly affected by the thermo-mechanical parameters. The serrated flow features are obvious under the testing conditions. A stacked auto-encoders (SAEs) network model is proposed for predicting the flow behaviors of the researched superalloy. The architecture of the established SAEs model is optimized layer by layer. The best number of hidden layer is 3, and the nodes per hidden layer are 15, 20 and 50, respectively. The excellent prediction ability suggests that the developed SAEs model can well reconstruct the intermediate-temperature flow behavior involving the PLC effects of the researched superalloy.

Graphic Abstract

Similar content being viewed by others

References

Y.C. Lin, F. Wu, Q.W. Wang, D.D. Chen, S.K. Singh, Microstructural evolution of a Ni–Fe–Cr-base superalloy during non-isothermal two-stage hot deformation. Vacuum 151, 283–293 (2018)

P.H. Geng, G.L. Qin, J. Zhou, Z.D. Zou, Hot deformation behavior and constitutive model of GH4169 superalloy for linear friction welding process. J. Manuf. Process. 32, 469–481 (2018)

D. Liao, S.P. Zhu, Energy field intensity approach for notch fatigue analysis. Int. J. Fatigue 127, 190–202 (2019)

D. Liao, S.P. Zhu, G. Qian, Multiaxial fatigue analysis of notched components using combined critical plane and critical distance approach. Int. J. Mech. Sci. 160, 38–50 (2019)

F. Chen, J. Liu, H.A. Ou, B. Lu, Z.S. Cui, H. Long, Flow characteristics and intrinsic workability of IN718 superalloy. Mater. Sci. Eng. A 642, 279–287 (2015)

Y.C. Lin, J. Deng, Y.Q. Jiang, D.X. Wen, G. Liu, Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Des. 55, 949–957 (2014)

J. Liu, W.T. Tang, J.H. Li, Deformation and fracture behaviors of K403 Ni-based superalloy at elevated temperatures. J. Alloys Compd. 699, 581–590 (2017)

X. Zhang, H.W. Li, M. Zhan, Mechanism for the macro and micro behaviors of the Ni-based superalloy during electrically-assisted tension: local Joule heating effect. J. Alloys Compd. 742, 480–489 (2018)

Y.C. Huang, C. Liu, Z.B. Xiao, Hot tensile deformation and fracture behaviours of Hastelloy C-276 alloy. Mater. Sci. Technol. 34, 620–627 (2018)

C.Y. Wang, Q.L. An, Q.L. Niu, M. Chen, Strain-rate sensitivity of tensile behaviors for nickel-based superalloys GH3044 and GH4033 at room temperature. Indian J. Eng. Mater. Sci. 23, 336–340 (2016)

Y.C. Lin, H. Yang, Y.C. Xin, C.Z. Li, Effects of initial microstructures on serrated flow features and fracture mechanisms of a nickel-based superalloy. Mater. Charact. 144, 9–21 (2018)

P. Maj, J. Zdunek, J. Mizera, K.J. Kurzydlowski, B. Sakowicz, M. Kaminski, Microstructure and strain–stress analysis of the dynamic strain aging in Inconel 625 at high temperature. Met. Mater. Int. 23, 54–67 (2017)

J.H. Kim, Y.S. Na, Tensile properties and serrated flow behavior of as-cast CoCrFeMnNi high-entropy alloy at room and elevated temperatures. Met. Mater. Int. 25, 296–303 (2019)

A.K. Gupta, H.N. Krishnamurthy, Y. Singh, K.M. Prasad, S.K. Singh, Development of constitutive models for dynamic strain aging regime in austenitic stainless steel 304. Mater. Des. 45, 616–627 (2013)

A. Garg, B.N. Panda, K. Tai, True stress measurement of nuclear fuel rod cladding material subjected to DSA regime. Neural Comput. Appl. 28, 119–126 (2017)

A. Garg, K. Tai, A.K. Gupta, A modified multi-gene genetic programming approach for modelling true stress of dynamic strain aging regime of austenitic stainless steel 304. Meccanica 49, 1193–1209 (2014)

Y.C. Lin, H. Yang, X.M. Chen, D.D. Chen, Influences of initial microstructures on Portevin–Le Chatelier effect and mechanical properties of a Ni–Fe–Cr-base superalloy. Adv. Eng. Mater. 20, 1800234 (2018)

Z.H. Cai, H. Ding, R.D.K. Misra, Z.Y. Ying, Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 84, 229–236 (2015)

F. Chmelık, E. Pink, J. Król, J. Balık, J. Pešička, P. Lukáč, Mechanisms of serrated flow in aluminium alloys with precipitates investigated by acoustic emission. Acta Mater. 46, 4435–4442 (1998)

P. Vincent, H. Larochelle, I. Lajoie, Y. Bengio, P.A. Manzagol, Stacked denoising autoencoders: learning useful representations in a deep network with a local denoising criterion. J. Mach. Learn. Res. 11, 3371–3408 (2010)

W. Li, M. Xiao, X. Peng, A. Garg, L. Gao, A surrogate thermal modeling and parametric optimization of battery pack with air cooling for EVs. Appl. Therm. Eng. 147, 90–100 (2019)

C. Ruhatiya, S. Singh, A. Goyal, X.D. Niu, T.N.H. Nguyen, V.H. Nguyen, V.M. Tran, M.L.P. Le, A. Garg, L. Gao, Electrochemical performance enhancement of sodium-ion batteries fabricated with NaNi1/3Mn1/3Co1/3O2 cathodes using support vector regression-simplex algorithm approach. J. Electrochem. Energy Convers. Storage (2019). https://doi.org/10.1115/1.4044358

M.F. Buchely, X. Wang, D.C. Van Aken, R.J. O’Malley, S. Lekakh, K. Chandrashekhara, The use of genetic algorithms to calibrate Johnson–Cook strength and failure parameters of AISI/SAE 1018 steel. J. Eng. Mater. Technol. 141, 021012 (2019)

A. Jenab, I.S. Sarraf, D.E. Green, T. Rahmaan, M.J. Worswick, The use of genetic algorithm and neural network to predict rate-dependent tensile flow behaviour of AA5182-O sheets. Mater. Des. 94, 262–273 (2016)

Y.C. Lin, F.Q. Nong, X.M. Chen, D.D. Chen, M.S. Chen, Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 137, 104–114 (2017)

M. Rakhshkhorshid, A robust RBF-ANN model to predict the hot deformation flow curves of API X65 pipeline steel. Int. J. Mater. Form. 4, 12–20 (2017)

D.D. Chen, Y.C. Lin, Fan Wu, A design framework for optimizing forming processing parameters based on matrix cellular automaton and neural network-based model predictive control methods. Appl. Math. Model. 76, 918–937 (2019)

G.Z. Quan, W.Q. Lv, Y.P. Mao, Y.W. Zhang, J. Zhou, Prediction of flow stress in a wide temperature range involving phase transformation for as-cast Ti–6Al–2Zr–1Mo–1V alloy by artificial neural network. Mater. Des. 50, 51–61 (2013)

A. Mirzaei, A. Zarei-Hanzaki, M.H. Pishbin, A. Imandoust, S. Khoddam, Evaluating the hot deformation behavior of a super-austenitic steel through microstructural and neural network analysis. J. Mater. Eng. Perform. 24, 2412–2421 (2015)

J. Cai, K.S. Wang, Y.Y. Han, A comparative study on Johnson Cook, Modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict high-temperature flow behavior of Ti–6Al–4V alloy in α + β phase. High Temp. Mater. Process. 35, 297–307 (2016)

Y.C. Lin, D.D. Chen, M.S. Chen, X.M. Chen, J. Li, A precise BP neural network-based online model predictive control strategy for die forging hydraulic press machine. Neural Comput. Appl. 29, 585–596 (2018)

Y.C. Lin, J. Li, M.S. Chen, Y.X. Liu, Y.J. Liang, A deep belief network to predict the hot deformation behavior of a Ni-based superalloy. Neural Comput. Appl. 29, 1015–1023 (2018)

Y.C. Lin, Y.J. Liang, M.S. Chen, X.M. Chen, A comparative study on phenomenon and deep belief network models for hot deformation behavior of an Al–Zn–Mg–Cu alloy. Appl. Phys. A 123, 68 (2017)

D.G. He, Y.C. Lin, J. Chen, D.D. Chen, J. Huang, Y. Tang, M.S. Chen, Microstructural evolution and support vector regression model for an aged Ni-based superalloy during two-stage hot forming with stepped strain rates. Mater. Des. 154, 51–62 (2018)

G.Z. Quan, Z.H. Zhang, Y.T. Zhou, T. Wang, Y.F. Xia, Numerical description of hot flow behaviors at Ti–6Al–2Zr–1Mo–1V alloy by GA-SVR and relative applications. Mater. Res. 19, 1253–1269 (2016)

D.D. Chen, Y.C. Lin, A particle swarm optimization-based multi-level processing parameters optimization method for controlling microstructures of an aged superalloy during isothermal forging. Met. Mater. Int. 25, 1246–1257 (2019)

D.D. Chen, Y.C. Lin, X.M. Chen, A strategy to control microstructures of a Ni-based superalloy during hot forging based on particle swarm optimization algorithm. Adv. Manuf. 7, 238–247 (2019)

D.D. Chen, Y.C. Lin, Y. Zhou, M.S. Chen, D.X. Wen, Dislocation substructures evolution and an adaptive-network-based fuzzy inference system model for constitutive behavior of a Ni-based superalloy during hot deformation. J. Alloys Compd. 708, 938–946 (2017)

H. Vafaeenezhad, S.H. Seyedein, M.R. Aboutalebi, A.R. Eivani, Application of constitutive description and integrated ANFIS–ICA analysis to predict hot deformation behavior of Sn-5Sb lead-free solder alloy. J. Alloys Compd. 697, 287–299 (2017)

ISO 6892-2: Metallic materials—tensile testing—part 2: method of test at elevated temperature (2011)

Y. Cai, C. Tian, G. Zhang, G. Han, S. Yang, S. Fu, C. Cui, Q. Zhang, Influence of γ′ precipitates on the critical strain and localized deformation of serrated flow in Ni-based superalloys. J. Alloys Compd. 690, 707–715 (2017)

Y.C. Lin, H. Yang, D.G. He, J. Chen, A physically-based model considering dislocation–solute atom dynamic interactions for a nickel-based superalloy at intermediate temperatures. Mater. Des. (2019). https://doi.org/10.1016/j.matdes.2019.108122

J. Yang, Y. Bai, F. Lin, M. Liu, Z. Hou, X. Liu, A novel electrocardiogram arrhythmia classification method based on stacked sparse auto-encoders and softmax regression. Int. J. Mach. Learn. Cybern. 9, 1733–1740 (2017)

R. Zhao, R. Yan, Z. Chen, K. Mao, P. Wang, R.X. Gao, Deep learning and its applications to machine health monitoring. Mech. Syst. Sig. Process. 115, 213–237 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation Council of China (Grant No. 51775564).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, Y.C., Yang, H., Chen, DD. et al. Stacked Auto-Encoder Network to Predict Tensile Deformation Behavior of a Typical Nickel-Based Superalloy Considering Portevin–Le Chatelier Effects. Met. Mater. Int. 27, 254–261 (2021). https://doi.org/10.1007/s12540-019-00435-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00435-8