Abstract

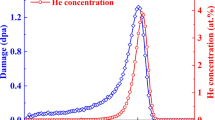

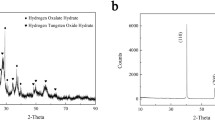

Transmission electron microscopy (TEM) and nanoindentation were performed in Hastelloy N alloy with three kinds of irradiation mode: single He ions, He + Xe (3 dpa) ions and He + Xe (10 dpa) ions. TEM results showed the presence of nano-sized irradiation-damage defects, such as helium bubbles, xenon bubbles, dislocation loops and precipitates. It was found that the helium bubble can grow up via absorbing vacancies, and the helium bubble shrinkage will be also occurred due to the helium atoms re-solution. In the case of He + Xe (3 dpa) ions irradiation, the helium bubble growth via absorbing vacancies induced by subsequent Xe ion irradiation was more noticeable. As for the sample irradiated by He + Xe (10 dpa) ions, the ion irradiation enhanced helium atoms re-solution played an important role. Moreover, the helium atoms were more easily dissolved from small helium bubbles and the mechanisms behind them have also been shed light on. In addition, the dispersed barrier hardening and strengthening superposition models were used to predict the nanohardness increments produced by the different irradiation defects. The nanohardness increments measured by nanoindentation for irradiated samples were basically consistent with the calculated nanohardness increments.

Graphic Abstract

Both the ballistic recoil re-solution and the damage assisted re-solution make it easier for helium atoms to dissolve from small helium bubbles.

Similar content being viewed by others

References

P. Yvon, F. Carré, J. Nucl. Mater. 385, 217–222 (2009)

A Technology Roadmap for Generation IV Nuclear Energy Systems, GIF-002–00, Issued by the U.S. DOE Nuclear Energy Research Advisory Committee and the Generation IV International Forum, December 2002.

J. Serp, M. Allibert, O. Benes, S. Delpech, O. Feynberg, V. Ghetta, D. Heuer, D. Holcomb, V. Ignatiev, J.L. Kloosterman, L. Luzzi, E. Merle-Lucotte, J. Uhlir, R. Yoshika, Z.M. Dai, Prog. Nucl. Ener 77, 208–319 (2014)

L.C. Olson, J.W. Ambrosek, K. Sridharan, James W. Ambrosek, Kumar Sridharan, Mark H. Anderson, Todd R. Allen, J. Fluorine. Chem. 130 (2009) 67–73.

H.E. McCoy, B. McNabb, ORNL/TM-4829, TN, USA, 1972, pp. 165–172.

Preliminary Fluoride Salt-Cooled High Temperature Reactor (FHR) Materials and Components White Paper, UCBTH-12–003, August 2012.

W.R. Martin, J.R. Weir, Nucl. Appl. 1, 160–167 (1965)

H.F. Huang, W. Zhang, M. De Los Reyes, X.L. Zhou, C. Yang, R. Xie, X.T. Zhou, P. Huai, H.J. Xu, Mater. Des. 90, 359–363. (2016)

C.-L. Chen, A. Richter, R. Kögler, J. Alloys Compd. 586, S173–S179 (2014)

H.F. Huang, J. Gao, B. Radiguet, R.D. Liu, J.J. Li, G.H. Lei, Q. Huang, M. Liu, R.B. Xie, J. Nucl. Mater. 499, 431–439 (2018)

M. Liu, Y.L. Lu, R.D. Liu, X.T. Zhou, Microsc. Res. Tech. 77, 161–169 (2014)

H.F. Huang, X.L. Zhou, C.W. Li, J. Gao, T. Wei, G.H. Lei, J.J. Li, L.F. Ye, Q. Huang, Z.Y. Zhu, J. Nucl. Mater. 497, 108–116 (2017)

J. Gao, L.M. Bao, H.F. Huang, Y. Li, J.R. Zeng, Z. Liu, R.D. Liu, L.Q. Shi, Materials 9, 832–836 (2016)

G.H. Lei, R.B. Xie, H.F. Huang, R.D. Liu, Q. Huang, J.J. Li, Y.Y. Zhou, C. Li, Q.T. Lei, Q. Deng, Y.Q. Wang, C.B. Wang, W. Zhang, L. Yan, M. Tang, J. Alloys Compd. 746, 153–158 (2018)

G.S. Was, J.T. Busby, T. Allen, E.A. Kenik, A. Jensson, S.M. Bruemmer, J. Gan, A.D. Edwards, P.M. Scott, P.L. Andreson, J. Nucl. Mater. 300, 198–216 (2002)

C. Heintze, F. Bergner, M. Hernández-Mayoral, J. Nucl. Mater. 417, 980–983 (2011)

P.P. Liu, F.R. Wan, Q. Zhan, Nucl. Instrum. Methods B 342, 13–18 (2015)

X.B. Liu, R.S. Wang, A. Ren, J. Jiang, C.L. Xu, P. Huang, W.J. Qian, Y.C. Wu, C.H. Zhang, J. Nucl. Mater. 444, 1–6 (2014)

J.F. Ziegler, J.P. Biersack, U. Littmark, The stopping and range of ions in matter (Pergamon Press, New York, 1985)

R.E. Stoller, M.B. Toloczko, G.S. Was, A.G. Certain, S. Dwaraknath, F.A. Garner, Nucl. Instrum. Methods Phys. B 310, 75–80 (2013)

W.C. Olivier, G.M. Pharr, J. Mater. Res. 19, 3–20 (2004)

W.C. Olivier, G.M. Pharr, J. Mater. Res. 7, 1564–1583 (1992)

F.F. Han, B.M. Zhou, H.F. Huang, B. Leng, Y.L. Lu, J.S. Dong, Z.J. Li, X.T. Zhou, Mater. Chem. Phys. 182, 22–31 (2016)

J. Gao, H.F. Huang, J.Z. Liu, Z.B. Zhu, Y. Li, J. Appl. Phys. 125, 055901 (2019)

H. Trinkaus, Scr. Metall. 23, 1773–1778 (1989)

J. Gao, H.F. Huang, J.Z. Liu, R.D. Liu, Q.T. Lei, Y. Li, J. Appl. Phys. 123, 205901 (2018)

Y.P. Wei, P.P. Liu, Y.M. Zhu, Z.Q. Wang, F.R. Wan, Q. Zhan, J. Alloys Compd. 676, 481–488 (2016)

D.C. Parfitt, R.W. Grimes, J. Nucl. Mater. 381, 216–222 (2008)

C. Ronchi, P.T. Elton, J. Nucl. Mater. 140, 228–244 (1986)

Z. Jiao, G.S. Was, Acta Mater. 59, 1220–1238 (2011)

W.D. Nix, H. Gao, J. Mech. Phys. Solids 46, 411–425 (1998)

S.X. Jin, L.P. Guo, Y.Y. Ren, R. Tang, Y.X. Qiao, J. Mater. Sci. Technol. 28(11), 1039–1045 (2012)

R. Kasada, Y. Takayama, K. Yabuuchi, A. Kimura, Fusion Eng. Des. 86, 2658–2661 (2011)

B. Radiguet, A. Etienne, P. Pareige, X. Sauvage, R. Valiev, J. Mater. Sci. 43, 7338–7343 (2008)

Y. Takayama, R. Kasada, Y. Sakamoto, K. Yabuuchi, A. Kimura, M. Ando, D. Hamaguchi, J. Nucl. Mater. 442, S23–S27 (2013)

X.B. Liu, R.S. Wang, A. Rei, J. Jiang, C.L. Xu, P. Huang, W.J. Qian, Y.C. Wu, C.H. Zhang, J. Nucl. Mater. 444, 1–6 (2014)

G.E. Lucas, J. Nucl. Mater. 206, 287–305 (1993)

A.J.E. Foreman, M.J. Makin, Can. J. Phys. 45, 511–517 (1967)

G.R. Odette, G.E. Lucas, Radiat Eff. Defects Solids 144, 189–231 (1998)

Y. Katoh, M. Ando, A. Kohyama, J. Nucl. Mater. 323, 251–262 (2003)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11605271 and 91126012), and the Youth Innovation Promotion Association, Chinese Academy of Sciences (Grant No. 2016239).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Huang, H., Liu, R. et al. Ion Irradiation Enhanced Helium Atoms Re-Solution and the Related Hardening in Hastelloy N Alloy. Met. Mater. Int. 27, 365–375 (2021). https://doi.org/10.1007/s12540-019-00427-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00427-8