Abstract

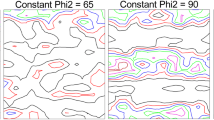

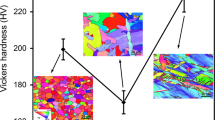

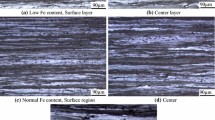

The Cu–3 wt%Ag–0.5 wt%Zr are rolled with the same reduction process at room (RT) and cryogenic (CT) temperature, respectively. The electron backscatter diffraction and transmission electron microscope are used to analyze and compare the evolutions of material microstructure and texture. The results show that the stability of as-rolled CT sheets is different from that of the RT samples, which can be verified by the lower temperature for the occurrence of recrystallization and Ag-base particles precipitation. Besides the Brass, Copper and S textures which are exhibited in the two kinds of as-rolled sheets, there are also Q and P texture components in the as-rolled CT sheets. The constitutive equation basing on evolution of dislocation mean free path (L) and dislocation cell size (dDC) with plastic strain indicates that the initial values of L, dDC and mobile dislocation density (ρm) are associated with annealing condition closely. Furthermore, the strain ranges of the stable and instable plastic deformation are related to the degree of recovery and recrystallization.

Graphic Abstract

Similar content being viewed by others

References

A. Vinogradov, Y. Estrin, Analytical and numerical approaches to modelling severe plastic deformation. Prog. Mater. Sci. 95, 172–242 (2018)

G. Faraji, H.S. Kim, H.T. Kashi, Severe Plastic Deformation Methods, Processing and Properties (Elsevier, Amsterdam, 2018). https://doi.org/10.1016/C2016-0-05256-7

L. Lapeire, J. Sidor, P. Verleysen, K. Verbeken, I. De Graeve, H. Terryn, L.A.I. Kestens, Texture comparison between room temperature rolled and cryogenically rolled pure copper. Acta Mater. 95, 224–235 (2015)

T. Konkova, S. Mironov, A. Korznikov, M.M. Myshlyaev, S.L. Semiatin, Annealing behavior of cryogenically-rolled copper. Mat. Sci. Eng. A. 585, 178–189 (2013)

Y. Lu, R. Ma, Y.N. Wang, Texture evolution and recrystallization behaviors of Cu–Ag alloys subjected to cryogenic rolling. Trans. Nonferrous Met. Soc. China 25, 2948–2957 (2015)

T. Konkova, S. Mironov, A. Korznikov, S.L. Semiatin, Microstructure instability in cryogenically deformed copper. Scr. Mater. 63, 921–924 (2010)

C. Saldana, A.H. King, S. Chandrasekar, Thermal stability and strength of deformation microstructures. Acta Mater. 60, 4107–4116 (2012)

D.A. Hughes, N. Hansen, The microstructural origin of work hardening stages. Acta Mater. 148, 374–383 (2018)

M.N. Bassim, C.D. Liu, Dislocation cell structures in copper in torsion and tension. Mater. Sci. Eng. A 164, 170–174 (1993)

E.I. Galindo-Nava, P.E.J. Rivera-Díaz-del-Castillo, A thermodynamic theory for dislocation cell formation and misorientation in metals. Acta Mater. 60, 4370–4378 (2012)

G. Chen, J.Z. Shen, Q. Zhu, S.J. Yao, C.J. Wang, P. Zhang, Tensile deformation and fracture behaviours of cold rolled Cu–3wt.%Ag–0.5wt.%Zr thin sheets with different annealed microstructures. Mater. Sci. Eng. A 756, 27–34 (2019)

P.S. Chen, J.H. Sanders, Y.K. Liaw et al., Ductility degradation of vacuum-plasma-sprayed NARloy-Z at elevated temperatures. Mater. Sci. Eng. A 199(2), 145–152 (1995)

C. Verdy, Ipsé—LERMPS. Phd thesis, Belfort, France, 1998, 279 pp

N. Hansen, X. Huang, D.A. Hughes, Microstructural evolution and hardening parameters. Mater. Sci. Eng. A 317, 3–11 (2001)

T.B. Yu, N. Hansen, X.X. Huang, Linking recovery and recrystallization through triple junction motion in aluminum cold rolled to a large strain. Acta Mater. 61, 6577–6586 (2013)

D.K. Wilsdorf, N. Hansen, Geometrically necessary, incidental and subgrain boundaries. Scr. Metall. Mater. 25, 1557–1562 (1991)

R.G. Li, S.J. Zhang, H.J. Kang, Z.N. Chen, F.F. Yang, W. Wang, C.L. Zou, T.J. Li, T.M. Wang, Microstructure and texture evolution in the cryorolled CuZr alloy. J. Alloys. Compd. 693, 592–600 (2017)

T. Konkova, S. Mironov, A. Korznikov, S.L. Semiatin, Microstructural response of pure copper to cryogenic rolling. Acta Mater. 58, 5262–5273 (2010)

Q.Q. Shao, L.H. Liu, T.W. Fan, D.W. Yuan, J.H. Chen, Effects of solute concentration on the stacking fault energy in copper alloys at finite temperatures. J. Alloys. Compd. 726, 601–607 (2017)

B.B. Zhang, N.R. Tao, K. Lu, A high strength and high electrical conductivity bulk Cu–Ag alloy strengthened with nanotwins. Scr. Mater. 129, 39–43 (2017)

T. Konkova, S. Mironova, A. Korznikov, G. Korznikova, M.M. Myshlyaev, S.L. Semiatin, An EBSD investigation of cryogenically-rolled Cu–30%Zn Brass. Mater. Charact. 101, 173–179 (2015)

K.S. Raju, V.S. Sarma, A. Kauffmann, Z. Hegedűs, J. Gubicza, M. Peterlechner, J. Freudenberger, G. Wilde, High strength and ductile ultrafine-grained Cu–Ag alloy through bimodal grain size, dislocation density and solute distribution. Acta Mater. 61(1), 228–238 (2013)

Z.P. Luo, H.W. Zhang, N. Hansen, K. Lu, Quantification of the microstructures of high purity nickel subjected to dynamic plastic deformation. Acta Mater. 60, 1322–1333 (2012)

P. Landau, R.Z. Shneck, G. Makov, A. Venkert, Microstructure evolution in deformed copper. J. Mater. Sci. 42, 9775–9782 (2007)

P. Landau, G. Makov, R.Z. Shneck, A. Venkert, Universal strain–temperature dependence of dislocation structure evolution in face-centered-cubic metals. Acta Mater. 59, 5342–5350 (2011)

J. Gan, J.S. Vetrano, M.A. Khaleel, Microstructure characterization of dislocation wall structure in aluminum using transmission electron microscopy. J. Mater. Sci. Technol. 124, 297–301 (2002)

C.Y. Yu, P.W. Kao, C.P. Chang, Transition of tensile deformation behaviors in ultrafine-grained aluminum. Acta Mater. 53, 4019–4028 (2005)

W. Piyawit, W.Z. Xu, S.N. Mathaudhu, J. Freudenberger, J.M. Rigsbee, Y.T. Zhu, Nucleation and growth mechanism of Ag precipitates in a CuAgZr alloy. Mater. Sci. Eng. A 610, 85–90 (2014)

S. Shao, J. Wang, A. Misra, Energy minimization mechanisms of semi-coherent interfaces. J. Appl. Phys. 116, 023508(1–10) (2014)

J.B. Liu, M.L. Hou, H.Y. Yang, H.B. Xie, C. Yang, J.D. Zhang, Q. Feng, L.T. Wang, L. Meng, H.T. Wang, In-situ TEM study of the dynamic interactions between dislocations and precipitates in a Cu–Cr–Zr alloy. J. Alloys. Compd. 765, 560–568 (2018)

H.D. Fu, S. Xu, W. Li, J.X. Xie, H.B. Zhao, Z.J. Pan, Effect of rolling and aging processes on microstructure and properties of Cu–Cr–Zr alloy. Mater. Sci. Eng. A 700, 107–115 (2017)

J. Gubicza, Z. Hegedűs, J.L. Lábár, A. Kauffmann, J. Freudenberger, V.S. Sarma, Solute redistribution during annealing of a cold rolled Cu–Ag alloy. J. Alloys. Compd. 623, 96–103 (2015)

B.B. Straumal, A.R. Kilmametov, A. Korneva, A.A. Mazilkin, P.B. Straumal, P. Zieba, B. Baretzky, Phase transitions in Cu-based alloys under high pressure torsion. J. Alloys. Compd. 707, 20–26 (2017)

U.F. Kocks, H. Mecking, Physics and phenomenology of strain hardening: the FCC case. Prog. Mater Sci. 48, 171–273 (2003)

R. Verier, Dislocation mean free path in copper at 77 K. Scr. Metall. 12, 69–73 (1978)

B. Devincre, T. Hoc, L. Kubin, Dislocation mean free paths and strain hardening of crystals. Science 320, 1745–1748 (2008)

C. Keller, E. Hug, Kocks–Mecking analysis of the size effects on the mechanical behavior of nickel polycrystals. Int. J. Plasticity 98, 106–122 (2017)

A.W. Thompson, M.I. Baskes, W.F. Flanagan, The dependence of polycrystal work hardening on grain size. Acta Metall. 21, 1017–1028 (1973)

A. Molinari, G. Ravichandran, Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech. Mater. 37, 737–752 (2005)

D. Kuhlmann-Wilsdorf, Theory of plastic deformation: properties of low energy dislocation structures. Mater. Sci. Eng. A 113, 1–41 (1989)

L.P. Kubin, Y. Estrin, Evolution of dislocation densities and the critical conditions for the portevin-le châtelier effect. Acta Metall. Mater. 38, 697–708 (1990)

N.Q. Chinh, T. Csanádi, J. Gubicza, T.G. Langdon, Plastic behavior of face-centered-cubic metals over a wide range of strain. Acta Mater. 58, 5015–5021 (2010)

Acknowledgements

This study was financially supported by the China Postdoctoral Science Foundation (No. 2017T100238) and Research and Development Plan in Shandong Province-Civil military integration of science and technology (No. 2016JMRH0107).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, P., Wang, H., Yao, S. et al. Effect of Annealing on the Microstructure, Texture and Tensile Deformation Properties of Cu–3 wt%Ag–0.5 wt%Zr Thin Sheets Rolled at Room and Cryogenic Temperature. Met. Mater. Int. 27, 392–402 (2021). https://doi.org/10.1007/s12540-019-00426-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00426-9