Abstract

The recognitions of phases and precise grain boundaries based on metallographic images are useful for conducting micromechanical simulations, such as finite element analysis and peridynamics. In this work, those processes are automatized by using a Sobel operator for identifying edges, which is normalized by different proposed Gaussian filters (on intensity, rugosity, or both). After that, a threshold is used to discretize the edges. Different neighboring pixel configurations, sensitive to edge intensity, are proposed for thinning and cleaning the discretized edges, and hence, grain boundaries with a one-pixel thickness are obtained. Then, the phase is selected by averaging color of each delimited grain. Finally, the precision on the phase recognition was found to increase from 75.61 to 83.6% for the unmodified and the normalized Sobel operator, respectively.

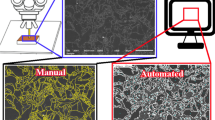

Graphic Abstract

Similar content being viewed by others

References

I. Alvarez-Armas, S. Degallaix-Moreuil, Duplex Stainless Steels (Wiley, New York, 2009)

I. Varol, J.C. Lippold, W.A. Baeslack, Welding of duplex stainless steels. Key Eng. Mater. 69–70, 217–252 (1992). https://doi.org/10.4028/www.scientific.net/KEM.69-70.217

V. Muthupandi, P.B. Srinivasan, S.K. Seshadri, S. Sundaresan, Mater. Sci. Eng., A 358, 9–16 (2003). https://doi.org/10.1016/S0921-5093(03)00077-7

I.N. Bastos, S.S.M. Tavares, F. Dalard, R.P. Nogueira, Scr. Mater. 57, 913–916 (2007). https://doi.org/10.1016/j.scriptamat.2007.07.037

V.S. Moura, L.D. Lima, J.M. Pardal, A.Y. Kina, R.R.A. Corte, S.S.M. Tavares, Mater. Charact. 59, 1127–1132 (2008). https://doi.org/10.1016/j.matchar.2007.09.002

J. Olsson, M. Snis, Desalination 205, 104–113 (2007). https://doi.org/10.1016/j.desal.2006.02.051

H.-Y. Liou, R.-I. Hsieh, W.-T. Tsai, Mater. Chem. Phys. 74, 33–42 (2002). https://doi.org/10.1016/S0254-0584(01)00409-6

H. Tan, Z. Wang, Y. Jiang, Y. Yang, B. Deng, H. Song, J. Li, Corros. Sci. 55, 368–377 (2012). https://doi.org/10.1016/j.corsci.2011.10.039

H. Schönheinz, G. Strang, G.J. Fix, An Analysis of the Finite Element Method. Series in Automatic Computation. XIV + 306 S. m. Fig (Prentice-Hall, Inc., Englewood Clifs, N. J., 1973) ZAMM J. Appl. Math. Mech./Zeitschrift Für Angew. Math. Und Mech. 55, 696–697 (1975). https://doi.org/10.1002/zamm.19750551121

J.N. Reddy, An Introduction To The Finite Element Method, 2nd edn. (McGraw-Hill, New York, 1993)

S.A. Silling, J. Mech. Phys. Solids 48, 175–209 (2000). https://doi.org/10.1016/S0022-5096(99)00029-0

S.A. Silling, M. Zimmermann, R. Abeyaratne, J. Elast. 73, 173–190 (2003). https://doi.org/10.1023/B:ELAS.0000029931.03844.4f

N. Moës, J. Dolbow, T. Belytschko, Int. J. Numer. Methods Eng. 46, 131–150 (1999). https://doi.org/10.1002/(SICI)1097-0207(19990910)46:1%3c131:AID-NME726%3e3.0.CO;2-J

R. Folch, J. Casademunt, A. Hernández-Machado, L. Ramírez-Piscina, Phys. Rev. E 60, 1734–1740 (1999). https://doi.org/10.1103/PhysRevE.60.1734

G.I. Barenblatt, The mathematical theory of equilibrium cracks in brittle fracture, in Advances in applied mechanics, ed. by H.L. Dryden, T. von Kármán, G. Kuerti, F.H. van den Dungen, L. Howarth (Elsevier, New York, 1962), pp. 55–129. https://doi.org/10.1016/S0065-2156(08)70121-2

W.K. Pratt, Digital Image Processing: PIKS Inside, 3rd edn. (Wiley, New York, 2001)

Z. Jin-Yu, C. Yan, and H. Xian-Xiang, Edge detection of images based on improved Sobel operator and genetic algorithms, in 2009 International Conference on Image and Signal Processing (2009), pp. 31–35. https://doi.org/10.1109/IASP.2009.5054605

V. Srinivasan, P. Bhatia, S.H. Ong, Pattern Recognit. 27, 1653–1662 (1994). https://doi.org/10.1016/0031-3203(94)90084-1

R. Wang, Edge detection using convolutional neural network BT—advances in neural networks—ISNN 2016, in ed. by L. Cheng, Q. Liu, A. Ronzhin (Springer, Cham, 2016), pp. 12–20

A.E. Mohamed, Y.A. Estaitia, M.A. Khafagy, Int. J. Adv. Comput. Sci. Appl. 4, 11–17 (2013). https://doi.org/10.14569/IJACSA.2013.041003

T.Y. Zhang, C.Y. Suen, A fast parallel algorithm for thinning digital patterns. Commun. ACM (1984). https://doi.org/10.1145/357994.358023

Z. Guo, R.W. Hall, Parallel thinning with two subiteration algorithms. Commun. ACM 15, 359–373 (1989). https://doi.org/10.1145/62065.62074

G.A. Story, L. O’Gorman, D. Fox, L.L. Schaper, H.V. Jagadish, The RightPages image-based electronic library for alerting and browsing. Computer 25, 17–26 (1992). https://doi.org/10.1109/2.156379

L. O’Gorman, Image and document processing techniques for the RightPages electronic library system, in Proceedings., 11th IAPR International Conference on Pattern Recognition. Vol. II. Conference B: Pattern Recognition Methodology and Systems (The Hague, Netherlands, 1992), pp. 260–263. https://doi.org/10.1109/ICPR.1992.201768

K. Chinnasarn, Y. Rangsanseri, P. Thitimajshima, Removing salt-and-pepper noise in text/graphics images, in IEEE. APCCAS 1998. 1998 IEEE Asia-Pacific Conference on Circuits and Systems. Microelectronics and Integrating Systems (Cat. No. 98EX242) (Chiangmai, Thailand, 1998), pp. 459–462. https://doi.org/10.1109/APCCAS.1998.743809

N. Jamil, T. Sembok, Z.A. Bakar, Noise removal and enhancement of binary images using morphological operations, in 2008 International Symposium on Information Technology (Kuala Lumpur, 2008), pp. 1–6. https://doi.org/10.1109/ITSIM.2008.4631954

H.S.M. Al-Khaffaf, A.Z. Talib, R.A. Salam, Removing salt-and-pepper noise from binary images of engineering drawings, in 19th International Conference on Pattern Recognition (2008), pp. 1–4. https://doi.org/10.1109/ICPR.2008.4761425

S. Pyatykh, J. Hesser, Salt and pepper noise removal in binary images using image block prior probabilities. J. Vis. Commun. Image Represent. 25, 748–754 (2014). https://doi.org/10.1016/j.jvcir.2014.02.001

J.Y. Kang, D.H. Kim, S.I. Baik, T.H. Ahn, Y.W. Kim, H.N. Han, K.H. Oh, H.C. Lee, S.H. Han, Phase analysis of steels by grain-averaged EBSD functions. ISIJ Int. 51, 130–136 (2011). https://doi.org/10.2355/isijinternational.51.130

C. Herrera, D. Ponge, D. Raabe, Design of a novel Mn-based 1 GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 59, 4653–4664 (2011). https://doi.org/10.1016/j.actamat.2011.04.011

R. Kaçar, Effect of solidification mode and morphology of microstructure on the hydrogen content of duplex stainless steel weld metal. Mater. Des. 25, 1–9 (2004). https://doi.org/10.1016/S0261-3069(03)00169-9

M.C. Young, L.W. Tsay, C.S. Shin, S.L.I. Chan, The effect of short time post-weld heat treatment on the fatigue crack growth of 2205 duplex stainless steel welds. Int. J. Fatigue 29, 2155–2162 (2007). https://doi.org/10.1016/j.ijfatigue.2007.01.004

M. Sadeghian, M. Shamanian, A. Shafyei, Effect of heat input on microstructure and mechanical properties of dissimilar joints between super duplex stainless steel and high strength low alloy steel. Mater. Des. 60, 678–684 (2014). https://doi.org/10.1016/j.matdes.2014.03.057

S. Topolska, J. Łabanowski, Impact-toughness investigations of duplex stainless steels. Mater. Technol. 49, 481–486 (2015). https://doi.org/10.17222/mit.2014.133

I.V. Aguiar, D. Pérez Escobar, D.B. Santos, P.J. Modenesi, Microstructure characterization of a duplex stainless steel weld by electron backscattering diffraction and orientation imaging microscopy techniques. Matéria (Rio J.) 20, 212–226 (2015). https://doi.org/10.1590/S1517-707620150001.0022

Acknowledgements

The authors acknowledge the Centro de Investigación en Corrosión of the Universidad Autónoma de Campeche for easing this work. This study has been funded by the Secretaría de Educación Pública of México, under the Project 511-6/18-8491 of the Apoyo a la incorporación de NPTC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Domínguez-Rodríguez, G., González-Sánchez, J.A., Rosado-Carrasco, J. et al. Grain Boundaries and Phases Identification of Metallographic Images by a Normalized Sobel Operation and the Edge Thinning Process for Further Numerical Simulation. Met. Mater. Int. 26, 1306–1317 (2020). https://doi.org/10.1007/s12540-019-00380-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00380-6