Abstract

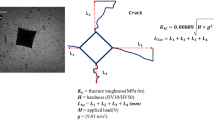

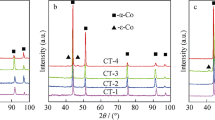

Cemented carbides have been of great interest within industrially manufacturable hard materials for their mechanical properties. Microwave sintering is known for its application on a range of hard materials. Although it has been widely used, its effect on grain growth of materials still requires clear understanding. Three different types of particle size, ranging from 1–3 µm to 100 nm were used for microwave sintering where temperature was used in this study within the range of 1000–1400 °C, while pressure during initial compaction of powder particles was kept constant. The maximum hardness was observed in the order of nearly 1800 Hv for submicron samples, sintered at 1250 °C. Fracture toughness on the samples reached a maximum of 16 MPa √m for micron samples sintered at 1400 °C. Grain growth in all samples was not more than 1–3 µm, even without the presence of any commercial grain growth inhibitors as part of the composition. Line scanning between grains demonstrates the presence of homogenous Co, confirming good mechanical behaviour. The microstructural features associated to the sintering process have also been focused as part of the study, highlighting some challenges in the research.

Graphic Abstract

Line scanning of WC (1–3 μm)–7.5 wt% Co (1–3 μm) sample, microwave sintered at 1400 °C

Similar content being viewed by others

References

M. Oghbaei, O. Mirzaee, J. Alloys Compd. 494, 175–189 (2010)

R.M. Raihanuzzaman, T.S. Jeong, R. Ghomashchi, Z. Xie, S.-J. Hong, J. Alloys Compd. 615, S564–S568 (2014)

Y.V. Bykov, K. Rybakov, V. Semenov, J. Phys. D Appl. Phys. 34, R55 (2001)

C.E. Holcombe, N.L. Dykes, M.S. Morrow. Thermal insulation for high temperature microwave sintering operations and method thereof. Google Patents, (1995)

D.E. Clark, W.H. Sutton, Annu. Rev. Mater. Sci. 26, 299–331 (1996)

K. Ro, K. Dreyer, T. Gerdes, M. Willert-Porada, Int. J. Refract. Met. Hard Mater. 16, 409–416 (1998)

D.E. Clark, D.C. Folz, J.K. West, Mater. Sci. Eng., A 287, 153–158 (2000)

R.C. Hoffmann, S. Sanctis, E. Erdem, S. Weber, J.J. Schneider, J. Mater. Chem. C 4, 7345–7352 (2016)

D.K. Agrawal, Curr. Opin. Solid State Mater. Sci. 3, 480–485 (1998)

R.M. Raihanuzzaman, L.C. Chuan, Z. Xie, R. Ghomashchi, World Acad. Sci. Eng. Technol. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 9, 930–933 (2015)

Z.-H. Xie, M. Hoffman, Y.B. Cheng, J. Am. Ceram. Soc. 85, 812–818 (2002)

H. Doi, Y. Fujiwara, K. Miyake, Y. Oosawa, Metall. Mater. Trans. 1, 1417–1425 (1970)

A. Santhanam, P. Tierney, J. Hunt, Metals Handbook, vol. 2, 10th edn. (ASM International, Materials Park, 1990), pp. 950–977

S. Coromant, Modern Metal Cutting: A Practical Handbook (Sandvik Coromant, Sandviken, 1994)

C. Morton, D. Wills, K. Stjernberg, Int. J. Refract. Met. Hard Mater. 23, 287–293 (2005)

A. Da Silva, W. Schubert, B. Lux, Mater. Res. 4, 59–62 (2001)

G. Shao, X. Duan, J. Xie, X. Yu, W. Zhang, R. Yuan, Rev. Adv. Mater. Sci. 5, 281–286 (2003)

B. Meredith, D. Milner, Powder Metall. 19, 38–45 (1976)

C. Martin, D. Bouvard, S. Shima, J. Mech. Phys. Solids 51, 667–693 (2003)

G. Aryanpour, M. Farzaneh, Powder Technol. 277, 120–125 (2015)

M.R. Rumman, Z. Xie, S.-J. Hong, R. Ghomashchi, Mater. Des. 68, 221–227 (2015)

J.-W. Song, R.M. Raihanuzzaman, S.-J. Hong, Powder Technol. 235, 723–727 (2012)

S.-J. Hong, M.R. Rumman, C.K. Rhee, Effect of Magnetic Pulsed Compaction (MPC) on Sintering Behavior of Materials (InTech Publication, Rijeka, 2012)

L. Sun, C. Jia, R. Cao, C. Lin, Int. J. Refract. Met. Hard Mater. 26, 357–361 (2008)

R.M. Raihanuzzaman, S.-T. Han, R. Ghomashchi, H.-S. Kim, S.-J. Hong, Int. J. Refract. Met. Hard Mater. 53, 2–6 (2015)

S.I. Cha, S.H. Hong, B.K. Kim, Mater. Sci. Eng. A 351, 31–38 (2003)

C.-C. Jia, H. Tang, X.-Z. Mei, F.-Z. Yin, X.-H. Qu, Mater. Lett. 59, 2566–2569 (2005)

S. Bhaumik, G. Upadhyaya, M. Vaidya, J. Mater. Process. Technol. 58, 45–52 (1996)

P. Kenny, Powder Met. 14, 22–38 (1971)

N. Ingelstrom, H. Nordberg, Eng. Fract. Mech. 6, 597–607 (1974)

G. Maizza, S. Grasso, Y. Sakka, T. Noda, O. Ohashi, Sci. Technol. Adv. Mater. 8, 644–654 (2007)

A. Michalski, D. Siemiaszko, Int. J. Refract. Met. Hard Mater. 25, 153–158 (2007)

R.M. Raihanuzzaman, J.H. Kim, J.K. Lee, J.S. Yoon, H.-T. Son, S.-J. Hong, Powder Technol. 225, 227–231 (2012)

S. Das, A. Mukhopadhyay, S. Datta, D. Basu, Bull. Mater. Sci. 32, 1–13 (2009)

D. Demirskyi, H. Borodianska, D. Agrawal, A. Ragulya, Y. Sakka, O. Vasylkiv, J. Alloys Compd. 523, 1–10 (2012)

E. Breval, J. Cheng, D. Agrawal, P. Gigl, M. Dennis, R. Roy, A. Papworth, Mater. Sci. Eng. A 391, 285–295 (2005)

V. Martínez, J. Echeberria, J. Am. Ceram. Soc. 90, 415–424 (2007)

S. Amberg, H. Doxner, Powder Metall. 20, 1–10 (1977)

W. Beere, Acta Metall. 23, 131–138 (1975)

F. Delannay, D. Pardoen, C. Colin, Acta Mater. 53, 1655–1664 (2005)

R.M. Raihanuzzaman, L.C. Chuan, Z. Xie, R. Ghomashchi, World Acad. Sci. Eng. Technol. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 9, 993–996 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rumman, R., Chuan, L.C., Quinton, J.S. et al. Mechanical Properties and Microstructural Behaviour of Microwave Sintered WC–Co. Met. Mater. Int. 26, 844–853 (2020). https://doi.org/10.1007/s12540-019-00364-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00364-6