Abstract

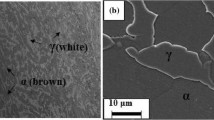

We investigated the change of precipitation behavior and impact resistance as a function of depth from the surface of thick block of SAF 2507 super duplex stainless steel with the thickness (T) of 200 mm after water quenching from 1050 °C. The amount of detrimental sigma phase increased smoothly until the depth of 0.25T, followed by a rapid increase from 0.25T to the center. However, the impact strength decreased significantly with only 1.3% of area fraction of sigma phase as the depth increased past 0.1T. Based on fractography analysis for the samples at such small depth ranges, the distance between the sigma phase particles affected the relative amount of initiating brittle cracks in front of the notch and was one of the crucial factors that dramatically reduced impact resistance with depth.

Similar content being viewed by others

References

J.O. Nilsson, Mater. Sci. Technol. 8, 685 (1992)

Y.H. Park, Z.H. Lee, Mater. Sci. Eng. A 297, 78 (2001)

H. Eriksson, S. Bernhardsson, Corrosion 47, 719 (1991)

D. Henes, R. Cordevener, S. Larsen, in Proceedings of Stainless Steel World (KCI publishing, Zutphen), p. 380 (2005)

D. Bruch, D. Henes, P. Leibenguth, C. Holzapfel, in Proc Stainless Steel World (Maastricht, The Netherland, 2007)

R.A. Perren, T. Suter, C. Solenthaler, G. Gullo, Corros. Sci. 43, 727 (2001)

G. Fargas, A. Mestra, A. Mateo, Wear 303, 584 (2013)

J.O. Nilsson, P. Kangas, T. Karlsson, A. Wilson, Met. Mater. Trans. A 31, 35 (2000)

K.M. Lee, H.S. Cho, D.C. Choi, J. Alloys Compd. 285, 156 (1999)

L. Karlsson, L. Bengtsson, U. Rolander, S. Pak, in Proceedings of Conference on Applications Stainless Steel (The Institute of Metal, Stockholm, Sweden, 1992), p. 335

R.N. Gunn, in Proceedings of Duplex America 2000 (KCI publishing, Zutphen, The Netherland, 2000), p. 299

L. Karlsson, S. Rigdal, F. Lake, in Proceedings of Conference on Duplex Stainless Steel (Duplex America, Houston, USA, 2000), p. 257

F. Tehovnik, B. Arzensek, B. Arh, D. Skobir, B. Pirnar, B. Zuzek, MTAEC9 45, 339 (2011)

I. Calliari, M. Breda, E. Ramous, M. Magrini, Convegno Naz. IGF XXII 1, 56 (2013)

I. Zucato, M.C. Moreira, I.F. Machado, S.M.G. Lebrao, Mater. Res. 5, 385 (2002)

S. Topolska, J. Łabanowski, Achiev. Mater. Manuf. Eng. 36, 142 (2009)

S.C. Kim, Z. Zhang, Y. Furuya, C.Y. Kang, J.H. Sung, Q.Q. Ni, Y. Watanabe, I.S. Kim, Mater. Trans. 46, 1656 (2005)

M. Martins, L.C. Casteletti, ASTM Int. 2, 1 (2005)

T.H. Hwang, J.H. Kim, K.H. Kim, W.J. Moon, C.Y. Kang, Met. Mater. Int. 20, 13 (2014)

I. Calliari, P. Bassani, K. Brunelli, M. Breda, E. Ramous, JMEPEG 22, 3860 (2013)

F. Danoix, M. Hedin, P. Auger, F. Cortial, A. Buchon, Mater. Sci. Eng. A 250, 14 (1998)

S.S. Sahay, G. Mohapatra, G.E. Totten, J. ASTM Int. 6, 1 (2009)

L.C. Burmeister, Convective Heat Transfer (Wiley, New York, 1983), pp. 567–577

J. Sengupta, B.G. Thomas, M.A. Wells, Met. Mater. Trans. A 36A, 187 (2005)

K. Nakade, T. Kuroda, J. High Temp. Soc. 33, 95 (2007)

T.M.R. Stainless, Practical Guidelines for the Fabrication of Duplex Stainless Steel, 3rd edn. (IMOA, London, 2014), p. 11

J.M. Pardal, S.S.M. Tavares, M.P. Cindra Fonseca, J.A. Souza, R.R.A. Corte, H.F.G. Abreu, Mater. Charact. 60, 165 (2009)

I. Calliari, K. Brunelli, M. Dabala, E. Ramous, Phase Trans. 61, 80 (2009)

J. Michalska, M. Sozanska, Mater. Charact. 56, 355 (2006)

D.M. Escriba, E.M. Morris, R.L. Plaut, A.F. Padilha, Mater. Charact. 60, 1214 (2009)

M. Dallali, M.A. Guidara, M.A. Bouaziz, C. Schmitt, E. Haj-Taie, Z. Azari, Eng. Fail. Anal. 51, 69 (2015)

H. Adib, S. Jallouf, C. Schmitt, A. Carmasol, G. Pluvinage, Int. J. Press. Vessels Pip. 84, 123 (2007)

I. Calliari, M. Zanesco, P. Bassani, E. Ramous, JOM 61, 80 (2009)

A. Ghosh, S. Sahoo, M. Ghosh, R.N. Ghosh, D. Chakrabarti, Mater. Sci. Eng. A 613, 37 (2014)

Acknowledgements

This work was supported by the Program of Core Technology Development on Industrial Materials, which is funded by the Ministry of Trade, Industry and Energy (No. 10042657), and partly by the Program of Fusion Alliance of Metallic Materials funded by Korea Institute of Advanced Technology (N0002590).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahiale, G.K., Kim, DH., Yang, WJ. et al. Change of Precipitation Behavior and Impact Toughness with Depths in Quenched Thick SAF 2507 Super Duplex Stainless Steel. Met. Mater. Int. 24, 738–745 (2018). https://doi.org/10.1007/s12540-018-0100-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0100-0