Abstract

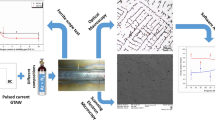

The gas metal arc weldability of 1.5 GPa grade martensitic (MART) steel was evaluated using both inverter direct current (DC) and DC pulse power type welders, under conditions of different welding currents, welding speeds, and shielding gasses. By investigating the bead appearance, tensile strength, and arc stability, it was determined that DC pulse power is better than inverter DC power for arc welding of 1.3 mm thick 1.5 GPa grade MART steel. Further, from the results of the weldability for various shielding gases, it was determined that mixed shielding gas is more effective for welding 1.5 GPa grade MART steel than is pure inert gas (Ar) or active (CO2) gas. In the case of pure shielding gas, no sound bead was formed under any conditions. However, when the mixed shielding gas was used, sound and fine beads were obtained.

Similar content being viewed by others

References

S. Zaefferer, J. Ohlert, and W. Bleck, Acta Mater. 52, 2765 (2004).

I. B. Timokhina, P. D. Hodgson, and E. V. Pereloma, Metall. Mater. Trans. A 35, 2331 (2004).

G. Frommeyer and U. Brux, Steel Res. Int. 77, 627 (2006).

S. Y. Han, S. Y. Shin, S. Lee, N. J. Kim, J. H. Kwak, and K. G. Chin, Korean J. Met. Mater. 48, 377 (2010).

B. W. Choi, D. H. Seo, and J. I. Jang, Metal. Mater. Int. 15, 373 (2009).

H. Oikawa, G. Murayama, S. Hiwatashi, and K. Matsuyama, Weld. World 51, 7 (2007).

R. Rauch, S. Kapl, G. Posch, and K. Radlmayr, BHM Bergund Hüttenmännische Monatshefte 157, 102 (2012).

R. Kuziak, R. Kawalla, and S. Waengler, Arch. Civ. Mech. Eng. 8, 103 (2008).

L. Bracke, K. Verbeken, L. Kestens, and J. Penning, Acta Mater. 57, 1512 (2009).

D. Barbier, N. Gey, S. Allain, N. Bozzolo, and M. Humbert, Mat. Sci. Eng. A 500, 196 (2009).

H.-C. Chen and G.-H. Cheng, J. Mater. Sci. 24, 1991 (1989).

N. Farabi, D. L. Chen, and Y. Zhou, J. Alloy. Compd. 509, 982 (2011).

A. Kumar, S. B. Singh, and K. K. Ray, Mat. Sci. Eng. A 474, 270 (2008).

M. Pouranvari and S. P. H. Marashi, Sci. Technol. Weld. Joi. 15, 149 (2010).

N. Fonstein, Advanced High Strength Sheet Steels: Physical Metallurgy, Design, Processing, and Properties, pp.259–263, Springer International Publishing, Switzerland (2015).

N. Yamauchi, K. Kunishige, T. Taka, and N. Nagao, Tetsu-to-Hagane 68, 1421 (1982).

P. K. Ghosh, P. C. Gupta, R. Avtar, and B. K. Jha, ISIJ Int. 30, 233 (1990).

W. Wang and S. Liu, Weld. J. 81, 132s (2002).

H. K. D. H. Bhadeshia and D. W. Suh, Ironmak. Steelmak. 42, 259 (2015).

E. C. Bain and H. W. Paxton, Alloying Elements in Steel, pp.65–67, American Society for Metals Metals Park, USA (1966).

Y. S. Jong, Y. K. Lee, D. C. Kim, M. J. Kang, I. S. Hwang, and W. B. Lee, Mater. Trans. 52, 1330 (2011).

V. H. Lopez-Cortez and F. A. Reyes-Valdes, Weld. J. 87, 36 (2008).

S. Vignier, E. Biro, and M. Herve, Weld. World 58, 297 (2014)

D. S. Safanama, S. P. H. Marashi, and M. Pouranvari, Sci. Technol. Weld. Joi. 17, 288 (2012).

M. Tamizi, M. Pouranvari, and M. Movahedi, Sci. Technol. Weld. Joi. 22, 327 (2017).

Y. Y. Zhao, Y. S. Zhang, and W. Hu, Sci. Technol. Weld. Joi. 18, 581 (2013).

C. Kim, M. J. Kang, and Y. D. Park, Procedia Engineer. 10, 2226 (2011).

H. Zhao and H. Liu, Trans. China Weld. Inst. 2, 67 (2014).

X. Li, G. Wang, G.-H. Liu, and H. Xu, J. Jilin University (Eng. Tech. Ed.) 44, 708 (2014).

F. Möller, H. Kügler, S. Kötschau, A. Geier, and S.-F. Goecke, Physics Proc. 56, 620 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, I., Yun, H., Kim, D. et al. Gas metal arc weldability of 1.5 GPa grade martensitic steels. Met. Mater. Int. 24, 149–156 (2018). https://doi.org/10.1007/s12540-017-7188-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-7188-5