Abstract

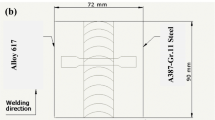

A filler metal wire, Alloy 625, was cladded on a plate of a low carbon streel, SS400, by gas tungsten arc welding, and the morphology of the weld bead and resulting dilution ratio were investigated under different welding parameter values (the input current, weld speed and wire feed speed). The wire feed speed was found to be most influential in controlling the dilution ratio of the weld bead, and seemed to limit the influence of other welding parameters. Two extreme welding conditions (with the minimum and maximum dilution ratios) were identified, and the corresponding microstructures, hardness and tensile properties near the bond line were compared between the two cases. The weld bead with the minimum dilution ratio showed superior hardness and tensile properties, while the formation lath martensite (due to relatively fast cooling) affected mechanical properties in the heat affected zone of the base metal with the maximum dilution ratio.

Similar content being viewed by others

References

I. A. Chaves, R. E. Melchers, Proc. 22nd International Offshore and Polar Engineering Conference, p. 158, International Society of Offshore and Polar Engineers, Rhodes, Greece (2012).

E. Nyman, Energy Research & Social Science 6, 1 (2015).

J. Bhandari, F. Khan, R. Abbassi, V. Garaniya, and R. Ojeda, J. Loss Prevent. Proc. 37, 39 (2015).

M. Finšgar and J. Jackson, Corros. Sci. 86, 17 (2014).

S. Nešić, Corros. Sci. 49, 4308 (2007).

Y. Hadji, A. Haddad, M. Yahi, M. E. A. Benamar, D. Miroud, M. Hadji, et al. Ceram. Int. 42, 1026 (2016).

M. Osman, M. Shalaby, Mater. Chem. Phys. 77, 261 (2003).

S. Kim, J. Jang, J. Kim, B. J. Kim, K. Y. Sohn, and D.-G. Nam, Korean J. Met. Mater. 54, 585 (2016).

H.-D. Im, W. Kil, K. Shin, B.-H. Koo, Korean J. Met. Mater. 51, 275 (2013).

M. Ericsson, R. Sandström, Int. J. Fatigue 25, 1379 (2003).

M. J. Moradi and M. Ketabchi, Indian J. Sci. Technol. 8, 1 (2015).

I. A. Chaves and R. E. Melchers, Corros. Sci. 53, 4026 (2011).

Z. Panossian, N. L. de Almeida, R. M. F. de Sousa, G. de Souza Pimenta, and L. B. S. Marques, Corros. Sci. 58, 1 (2012).

Y. Ahn, B. Yoon, H. Kim, and C. Lee, Met. Mater. Int. 8, 469 (2002).

C.-M. Lin, J.-J. Liu, H.-L. Tsai, and C.-M. Cheng, J. Chin. Inst. Eng. 34, 1013 (2011).

J. Wang, M.-X. Lu, L. Zhang, W. Chang, L.-N. Xu, and L.-H. Hu, Int. J. Min. Met. Mater. 19, 518 (2012).

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, J. Mater. Process. Tech. 209, 3628 (2009).

C.-M. Lin, H.-L. Tsai, and C. Yang, Surf. Coat. Tech. 206, 2673 (2012).

J. S. Kim, Y. I. Park, and H. W. Lee, Met. Mater. Int. 21, 350 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lou, S., Lee, S.B., Nam, DG. et al. Microstructures and mechanical properties of bonding layers between low carbon steel and alloy 625 processed by gas tungsten arc welding. Met. Mater. Int. 23, 1168–1175 (2017). https://doi.org/10.1007/s12540-017-7167-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-7167-x