Abstract

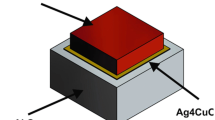

To fabricate a multi-layered structure for maximizing oxygen production, oxygen transport membrane (OTM) ceramics need to be joined or sealed hermetically metal supports for interfacing with the peripheral components of the system. Therefore, in this study, Ag–10 wt% CuO was evaluated as an effective filler material for the reactive air brazing of dense Ce0.9Gd0.1O2–δ–La0.7Sr0.3MnO3±δ (GDC–LSM) OTM ceramics. Thermal decomposition in air and wetting behavior of the braze filler was performed. Reactive air brazing was performed at 1050 °C for 30 min in air to join GDC–LSM with four different commercially available high temperature-resistant metal alloys, such as Crofer 22 APU, Inconel 600, Fecralloy, and AISI 310S. The microstructure and elemental distribution of the ceramic-ceramic and ceramic-metal interfaces were examined from polished cross-sections. The mechanical shear strength at room temperature for the as-brazed and isothermally aged (800 °C for 24 h) joints of all the samples was compared. The results showed that the strength of the ceramic-ceramic joints was decreased marginally by aging; however, in the case of metal-ceramic joints, different decreases in strengths were observed according to the metal alloy used, which was explained based on the formation of different oxide layers at the interfaces.

Similar content being viewed by others

References

J. Sunarso, S. Baumann, J. M. Serra, W. A. Meulenberg, S. Liu, J. C. Diniz da Costa, et al. J. Membrane Sci. 320, 13 (2008).

S. Baumann, J. M. Serra, M. P. Lobera, S. Escolástico, F. Schulze-Küppers, and W. A. Meulenberg, J. Membrane Sci. 377, 198 (2011).

S. Baumann, W. A. Meulenberg, and H. P. Buchkremer, J. Eur. Ceram. Soc. 33, 1251 (2013).

M. Katsuki, S. Wang, M. Dokiya, and T. Hashimoto, Solid State Ionics 156, 453 (2003).

H. Wang, R. Wang, D. T. Liang, and W. Yang, J. Membrane Sci. 243, 405 (2004).

Y. Zou, W. Zhou, S. Liu, and Z. Shao, J. Eur. Ceram. Soc. 31, 2931 (2011).

F. Schulze-Küppers, S. Baumann, W. A. Meulenberg, D. Stöver, and H. P. Buchkremer, J. Membrane Sci. 433, 121 (2013).

K. Zhang, J. Sunarso, Z. Shao, W. Zhou, C. Sun, S. Liu, et al. RSC Adv. 1, 1661 (2011).

J. H. Joo, K. S. Yun, Y. Lee, J. Jung, C.-Y. Yoo, and J. H. Yu, ACS Appl. Mater. Inter. 7, 14699 (2015).

R. W. Messler, Joining of Advanced Materials, pp.509–538, Butterworth-Heinemann, New York, USA (1994).

M. G. Nicholas, Joining of Ceramics, pp.128–154, Chapman and Hall, Lincoln, USA (1990).

K. Raju, Muksin, S. Kim, K. Song, J. H. Yu, and D.-H. Yoon, Mater. Design 109, 233 (2016).

J. Y. Kim, J.-P. Choi, and K. S. Weil, Int. J. Hydrogen Energ. 33, 3952 (2008).

K. S. Weil, J. Y. Kim, and J. S. Hardy, Electrochem. Solid St. 8, A133 (2005).

Y. Zhao, J. Malzbender, and S. M. Gross, J. Eur. Ceram. Soc. 31, 541 (2011).

J. Y. Kim, J. S. Hardy, and K. S. Weil, Int. J. Hydrogen Energ. 32, 3655 (2007).

O. M. Akselsen, J. Mater. Sci. 27, 1989 (1992).

O. M. Akselsen, J. Mater. Sci. 27, 569 (1992).

M. S. Reichle, T. Koppitz, and U. Reisgen, Weld. J. 89, 57 (2010).

J. Y. Kim, J. S. Hardy, and K. S. Weil, J. Am. Ceram. Soc. 88, 2521 (2005).

K. Raju, Muksin, and D.-H. Yoon, Ceram. Int. 42, 16392 (2016).

J. S. Hardy, J. Y. Kim, and K. S. Weil, J. Electrochem. Soc. 151, J43 (2004).

V. V. Joshi, A. Meier, J. Darsell, K. S. Weil, and M. Bowden, J. Mater. Sci. 48, 7153 (2013).

H. Chen, L. Li, R. Kemps, B. Michielsen, M. Jacobs, V. Middelkoop, et al. Acta Mater. 88, 74 (2015).

K. M. Erskine, A. M. Meier, and S. M. Pilgrim, J. Mater. Sci. 37, 1705 (2002).

W. Z. Zhu and S. C. Deevi, Mat. Sci. Eng. A 348, 227 (2003).

Z. Yang, K. S. Weil, D. M. Paxton, and J. W. Stevenson, J. Electrochem. Soc. 150, A1188 (2003).

A. M. Meier, P. Chidambaram, and G. R. Edwards, J. Mater. Sci. 30, 4781 (1995).

S. Kim, J. H. Joo, S.-D. Kim, and S.-K. Woo, Ceram. Int. 39, 9223 (2013).

J. T. Darsell and K. S. Weil, J. Phase Equilib. Diff. 27, 92 (2006).

Z. B. Shao, K. R. Liu, L. Q. Liu, H. K. Liu, and S. X. Dou, J. Am. Ceram. Soc. 76, 2663 (1993).

J. Y. Kim, J. S. Hardy, and K. S. Weil, J. Mater. Res. 20, 636 (2005).

J. Y. Kim and K. S. Weil, J. Am. Ceram. Soc. 90, 3830 (2007).

J. W. Fergus, Mat. Sci. Eng. A 397, 271 (2005).

K. Przybylski, T. Brylewski, E. Durda, R. Gawel, and A. Kruk, J. Therm. Anal. Calorim. 116, 825 (2014).

S. Molin, M. Chen, and P. V. Hendriksen, J. Power Sources 251, 488 (2014).

N. J. Magdefrau, L. Chen, E. Y. Sun, and M. Aindow, J. Power Sources 241, 756 (2013).

R. Sachitanand, M. Sattari, J.-E. Svensson, and J. Froitzheim, Int. J. Hydrogen Energ. 38, 15328 (2013).

R. Kiebach, K. Engelbrecht, L. Grahl-Madsen, B. Sieborg, M. Chen, J. Hjelm, et al. J. Power Sources 315, 339 (2016).

A. Pönicke, J. Schilm, M. Kusnezoff, and A. Michaelis, Fuel Cells 15, 735 (2015).

J. Xiao, N. Prudhomme, N. Li, and V. Ji, Appl. Surf. Sci. 284, 446 (2013).

N. C. Alstrup, N. Langvad, and I. Chorkendorff, Surf. Interface Anal. 22, 441 (1994).

A. Laik, P. Mishra, K. Bhanumurthy, G. B. Kale, and B. P. Kashyap, Acta Mater. 61, 126 (2013).

S. K. Sharma, G. D. Ko, and K. J. Kang, J. Eur. Ceram. Soc. 29, 355 (2009).

C. Cionea, M. D. Abad, Y. Aussat, and D. Frazer, Sol. Energ. Mat. Sol. C. 144, 235 (2016).

H. T. Zheng, Adv. Mat. Res. 941, 212 (2014).

S. Shibagaki, A. Koga, and Y. Shirakawa, Thin Solid Films 303, 101 (1997).

M. Singh, T. P. Shpargel, and R. Asthana, Int. J. Appl. Ceram. Tech. 4, 119 (2007).

D. Liu, H. W. Niu, Y. H. Zhou, X. G. Song, D. Y. Tang, and J. C. Feng, Mater. Design 87, 42 (2015).

X. Dai, J. Cao, J. Liu, D. Wang, and J. Feng, Mat. Sci. Eng. A 646, 182 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

FR, W.M., Yoon, DH., Raju, K. et al. Interfacial microstructure and shear strength of reactive air brazed oxygen transport membrane ceramic–metal alloy joints. Met. Mater. Int. 24, 157–169 (2018). https://doi.org/10.1007/s12540-017-7160-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-7160-4