Abstract

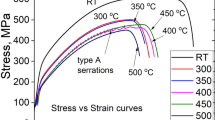

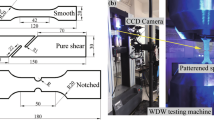

This paper is concerned with the construction of an empirical model of the Ductile-to-Brittle Transition Temperature (DBTT) for 3.4% silicon steel based on tensile test results at strain rates ranging from 0.001 s‒1 to 100 s‒1. Dynamic tensile tests are conducted using an in-house servo hydraulic tensile test machine at strain rates of 1 s‒1, 10 s‒1, and 100 s‒1 and quasi-static tensile tests are conducted using Instron 4206 at strain rates of 0.001 s‒1 and 0.01 s‒1 with an environmental chamber. Fracture elongations are measured by a DIC method during all tests using the high-speed camera for accurate measurement. The DBTT of 3.4% silicon steel is presented in terms of fracture strain with the variation of the temperature and the strain rate. It is demonstrated from the test results that the DBTT increases as the strain rate increases. An empirical model of the DBTT is constructed in terms of strain rate, temperature and fracture elongation. The parameters of the empirical model are calculated from experimental results obtained at various temperatures and strain rates.

Similar content being viewed by others

References

A. J. Moses, J. Magn. Magn. Mater. 112, 150 (1992).

Y. G. Ko, H. W. Yang, and J. H. Park, Korean J. Met. Mater. 53, 244 (2015).

K. Honma, T. Nozawa, H. Kobayashi, Y. Shimoyama, I. Tachino, and K. iyoshi, IEEE T. Magn. 21, 1903 (1985).

A. J. Moses, IEE Proc.-A 137, 233 (1990).

S.-J. Choi, H.-D. Joo, J.-T. Park, and N.-J. Park, Korean J. Met. Mater. 54, 540 (2016).

Y. Sato, T. Sato, and Y. Okazaki, Mater. Sci. Eng. 99, 73 (1988).

T. Yamaji, M. Abe, Y. Takada, K. Okada, and T. Hiratani, J. Magn. Magn. Mater. 133, 187 (1994).

M. A. Meyers and K. K. Chawla, Mechanical Behavior of Materials, 2 nd ed., pp. 480–485, Cambridge University Press, Cambridge, UK (2009).

W. Lei, X. Van, and M. Yao, Eng. Fract. Mech. 46, 583 (1993).

J. M. Baik, J. Kameda, and O. Buck, The Use of Small-Scale Specimens for Testing Irradiated Material, ASTM STP 888, p. 92, ASTM International, USA (1986).

T. Misawa, T. Adachi, M. Saito, and Y. Hamaguchi, J. Nucl. Mater. 150, 194 (1987).

M. Eskner and R. Sandström, Surf. Coat. Tech. 165, 71 (2003).

G. Kohse, M. Ames, and O. K. Harling, J. Nucl. Mater. 141, 513 (1986).

M. Z. Alam, D. Chatterjee, S. V. Kamat, V. Jayaram, and D. K. Das, Mat. Sci. Eng. A 527, 7147 (2010).

D. Pan, M. W. Chen, P. K. Wright, and K. J. Hemker, Acta Mater. 51, 2205 (2003).

A. K. Ray, B. Goswami, M. P. Singh, D. K. Das, N. Roy, A. K. Ray, et al. Mater. Charact. 57, 199 (2006).

A. K. Ray, N. Roy, A. Kar, A. K. Ray, S. C. Bose, G. Das, S. V. Joshi, et al. Mat. Sci. Eng. A 505, 96 (2009).

H. Huh, J. H. Lim, and S. H. Park, Int. J. Automot. Techn. 10, 195 (2009).

M. Kang, H. Kim, S. Lee, and S. Y. Shin, Met. Mater. Int. 21, 628 (2015).

A. Bhanage, N. Satonkar, P. Deshmukh, and R. Sundge, Int. J. Eng. Techn. 6, 2129 (2014).

B. J. Kim, R. Kasada, A. Kimura, and H. Tanigawa, J. Nucl. Mater. 417, 135 (2011).

J. Capelle, J. Furtado, Z. Azari, S. Jallais, and G. Pluvinage, Eng. Fract. Mech. 110, 270 (2013).

C. M. Moura, J. J. Vilela, E. G. Rabello, D. G. P. Martins, and J. R. G. Carneiro, Proc. INAC 2009, Rio de Janeiro, Brazil (2009).

S. A. Khan, P. Chivavibul, P. Sedlak, S. Arai, and M. Enoki, Metall. Mater. Trans. A 44, 3623 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, J., Huh, H. & Kim, Js. Evaluation of the ductile-to-brittle transition temperature of a silicon steel under various strain rate conditions with a servo-hydraulic high speed testing machine. Met. Mater. Int. 23, 736–744 (2017). https://doi.org/10.1007/s12540-017-6703-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6703-z