Abstract

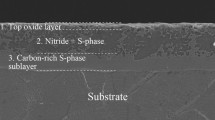

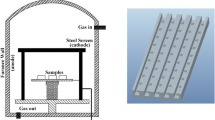

Plasma nitrocarburizing was performed on solution-treated AISI 630 martensitic precipitation hardening stainless steel samples with a gas mixture of H2, N2, and CH4 with changing temperature, discharge voltage and amount of CH4. When nitrocarburized with increasing temperature from 380 °C to 430 °C at fixed 25% N2 and 6% CH4, the thickness of expanded martensite (α'N) layer and surface hardness increased up to 10 μm and 1323 HV0.05, respectively but the corrosion resistance decreased. Though the increase of discharge voltage from 400 V to 600 V increased α'N layer thickness and surface hardness (up to 13 μm and 1491 HV0.05, respectively), the treated samples still showed very poor corrosion behavior. Thus, to further improve the corrosion resistance, the influence of variation of the amount of CH4 in the nitrocarburizing process was investigated. Increasing the CH4 percentage aided higher corrosion resistance, although it decreased the α'N layer thickness. The most appropriate conditions for moderate α'N layer thickness, high surface hardness and better corrosion resistance than the solution-treated bare sample were established, which is plasma nitrocarburizing at 400 °C with 400 V discharge voltage and containing 25% N2 and 4% CH4.

Similar content being viewed by others

References

Y. Xi, D. Liu, and D. Han, Surf. Coat. Tech. 202, 2577 (2008).

Y. Xi, D. Liu, and D. Han, Appl. Surf. Sci. 254, 5953 (2008).

M. F. Yan and R. L. Liu, Appl. Surf. Sci. 256, 6065 (2010).

Z. L. Zhang and T. Bell, Surf. Eng. 1, 131 (1985).

E. Menthe, K.-T. Rie, J. W. Schultze, S. Simson, Surf. Coat. Tech. 74-75, 412 (1995).

Z. Cheng, C. X. Li, H. Dong, and T. Bell, Surf. Coat. Tech. 191, 195 (2005).

T. Bell, Y. Sun, and A. Suhadi, Vacuum 59, 14 (2000).

M. K. Lei, Y. X. Ou, K. S. Wang, and L. Chen, Surf. Coat. Tech. 205, 4602 (2011).

I. Lee, Met. Mater. Int. 14, 77 (2008).

R. L. Liu and M. F. Yan, Mater. Design 31, 2355 (2010).

R. L. Liu, Y. J. Qiao, M. F. Yan, and Y. D. Fu, Met. Mater. Int. 19, 1151 (2013).

R. L. Liu and M. F. Yan, Surf. Coat. Tech. 204, 2251 (2010).

A. Fossati, F. Borgioli, E. Galvanetto, and T. Bacci, Corros. Sci. 48, 1513 (2006).

C. Li and T. Bell, Corros. Sci. 46, 1527 (2004).

S. P. Brühl, R. Charadia, S. Simison, D. G. Lamas, and A. Cabo, Surf. Coat. Tech. 204, 3280 (2010).

G. F. Vander Voort and E. P. Manilova, Adv. Mater. Process. 163, 32 (2005)

S. Kim, J. Yoo, J. Priest, and M. Fewell, Surf. Coat. Tech. 163-164, 380 (2003).

P. Kochmanski and J. Nowacki, Surf. Coat. Tech. 202, 4834 (2008).

F. Mahboubi and K. Abdolvahabi, Vacuum 81, 239 (2006).

S. Leigh, M. Samandi, G. Collins, K. T. Short, P. Martin, and L. Wielunski, Surf. Coat. Tech. 85, 37 (1996).

Y. Sun and E. Haruman, Vacuum 81, 114 (2006).

J. R. G. da Silva and R. B. McLellan, Mater. Sci. Eng. 26, 83 (1976).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, I. Influence of processing parameters on the characteristics of surface layers of low temperature plasma nitrocarburized AISI 630 martensitic stainless steel. Met. Mater. Int. 23, 1112–1120 (2017). https://doi.org/10.1007/s12540-017-6491-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6491-5