Abstract

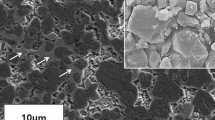

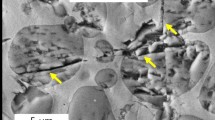

A particulate TiC-reinforced SKD11 steel matrix composite is fabricated by using a pressure infiltration casting, achieving a homogeneous distribution of the particles with 60 vol%. The retained austenite fraction in the composite matrix is approximately 19% after quenching from the austenitization temperature of 1010 °C, which is larger than 13% in as-quenched condition of unreinforced SKD11. A combined analysis on the austenite lattice parameter using XRD profiles and first-principle calculation suggests the increase of carbon content in the steel matrix possibly by partial dissolution of TiC during casting. The change of carbon content and prior austenite grain size reasonably accounts for the increase of retained austenite fraction in the composite matrix. In the austenitizing temperatures ranging from 950 °C to 1040 °C, the retained austenite fraction in the composite matrix in as-quenched condition increases more rapidly than that of unreinforced SKD11 with the increase of austenitization temperature, while the hardness of the composite is less sensitive to the austenitization temperature. This suggests that it is advantageous to conduct the austenitization at a temperature below 1010 °C, which is typical practice of austenitization of the unreinforced SKD11, because the retention of austenite is effectively suppressed while minimizing the loss of hardness.

Similar content being viewed by others

References

K. U. Kainer, Metal Matrix Composites: Custom-made Materials for Automotive and Aerospace Engineering, pp. 1–4, Wiley-VCH, Weinheim (2006).

I. A. Ibrahim, F. A. Mohamed, and E. J. Lavernia, J. Mater. Sci. 26, 1137 (1991).

S. C. Tjong and Z. Y. Ma, Mater. Sci. Eng. R 29, 49 (2000).

J.-W. Kim, J.-M. Lee, J.-H. Lee, and J.-C. Lee, Met. Mater. Int. 20, 1151 (2014).

J. Zhang, J.-M. Lee, Y.-H. Cho, S.-H. Kim, and H. Yu, Met. Mater. Int. 22, 324 (2016).

I.-J. Shon, S.-M. Kwon, N.-R. Park, J.-W. Shin, S.-H. Oh, and B.-S. Kim, Korean J. Met. Mater. 53, 555 (2015).

E. Pagounis and V. K. Lindroos, Mater. Sci. Eng. A 246, 221 (1998).

M. Kiviö, L. Holappa, T. Yoshikawa, and T. Tanaka, High Temp. Mater. Proc. 31, 645 (2012).

K. I. Parashivamurthy, R. K. Kumar, S. Seetharamu, and M. N. Chandrasekharaiah, J. Mater. Sci. 36, 4519 (2001).

F. Akhtar, Can. Metall. Quart. 53, 253 (2014).

T. S. Srivatsan, R. Annigeri, and A. Prakash, Compos. Part A-Appl. S. 28, 377 (1997).

R. K. Galgali, H. S. Ray, and A. K. Chakrabarti, Mater. Sci. Technol. 15, 437 (1999).

N. R. Oh, S. K. Lee, K. C. Hwang, and H. U. Hong, Scripta Mater. 112, 123 (2016).

A. J. Cook and P. S. Werner, Mater. Sci. Eng. A 144, 189 (1991).

L. C. Canale, R. A. Mesquita, and G. E. Totten, Failure Analysis of Heat Treated Steel Components, pp. 327–329, ASM International, Ohio (2008).

H. M. Rietveld, Acta Crystallogr. 22, 151 (1967).

E. Rabkin and L. Klinger, Mater. Sci. Technol. 17, 772 (2001).

P. Hohenberg and W. Kohn, Phys. Rev. 136, 864 (1964).

W. Kohn and L. J. Sham, Phys. Rev. 140, 1133 (1965).

G. Kresse and J. Furthmüller, Comp. Mater. Sci. 6, 15 (1996).

G. Kresse and J. Furthmüller, Phys. Rev. B 54, 11169 (1996).

P. E. Blöchl, Phys. Rev. B 50, 17953 (1994).

J. P. Perdew and Y. Wang, Phys. Rev. B 45, 13244 (1992).

J. P. Perdew, K. Burke, and M. Ernzerhof, Phys. Rev. Lett. 77, 3865 (1996).

J. O. Andersson, T. Helander, L. Höglund, P. F. Shi, and B. Sundman, Calphad 26, 273 (2002).

M. Foller and H. Meyer, Proceedings of the 6th International Tooling Conference (eds. Jens Bergström, G. Fredriksson, M. Johansson, O. Kotik, and F. Thuvander), pp. 1373–1389, Karlstad University, Karlstad (2002).

E. Pagounis, E. Haimi, J. Pietikainen, M. Talvitie, S. Vahvaselka, and V. K. Lindroos, Scripta Mater. 34, 407 (1996).

N. Ridley, H. Stuart, and L. Zwell, T. Metall. Soc. AIME 245, 1834 (1969).

C. S. Roberts, T. Metall. Soc. AIME 197, 203 (1953).

B. D. Butler and J. B. Cohen, J. Phys. I 2, 1059 (1992).

B. D. Butler and J. B. Cohen, Ultramicroscopy 52, 238 (1993).

D. E. Jiang and E. A. Carter, Phys. Rev. B 67, 214103 (2003).

P. Payson and C. H. Savage, T. Metall. Soc. ASM 33, 261 (1944).

E. S. Rowland and S. R. Lyle, T. Metall. Soc. ASM 37, 27 (1946).

R. A. Grange and H. M. Stewart, T. Metall. Soc. AIME 167, 467 (1946).

A. E. Nehrenberg, T. Metall. Soc. AIME 167, 494 (1946).

W. Steven and A. G. Haynes, J. Iron Steel. Res. Int. 183, 349 (1956).

K. W. Andrews, J. Iron Steel. Res. Int. 203, 721 (1965).

K. Ishida, J. Alloy. Compd. 220, 126 (1995).

C. Capdevila, F. G. Caballero, and C. G. de Andres, ISIJ Int. 42, 894 (2002).

S. J. Lee and K. S. Park, Metall. Mater. Trans. A 44, 3423 (2013).

S. Takaki, K. Fukunaga, J. Syarif, and T. Tsuchiyama, Mater. Trans. 45, 2245 (2004).

A. García-Junceda, C. Capdevila, F. G. Caballero, and C. García de Andrés, Scripta Mater. 58, 134 (2008).

H. S. Yang and H. K. D. H. Bhadeshia, Scripta Mater. 60, 493 (2009).

W. J. Harris and M. Cohen, T. Metall. Soc. AIME 180, 447 (1949).

H. K. D. H. Bhadeshia and R. Honeycombe, Steels: Microstructure and Properties, 3rd ed., pp. 72–73, Butterworth-Heinemann, Burlington (2011).

G. Krauss, Hardenability Concepts with Applications To Steel (eds. D. V. Doane and J. S. Kirkaldy), pp. 229–248, Metallurgical Society of AIME, Chicago (1978).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.H., Kim, D.H., Hwang, KC. et al. Heat treatment response of TiC-reinforced steel matrix composite. Met. Mater. Int. 22, 935–941 (2016). https://doi.org/10.1007/s12540-016-6176-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-6176-5