Abstract

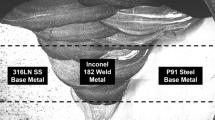

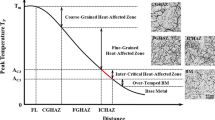

The objective of the present study was to elucidate the cavity formation mechanism of Type IV failure in weldment of advanced high-Cr ferritic steels. A welded joint of Mod.9Cr-1Mo steel was creep tested at 650 °C under 83 MPa. The creep fracture mode was Type IV failure in the heat affect zone (HAZ). Microstructural characterization of the HAZ and the fracture location, were performed before and after the creep test. The Type IV cracking started in the inter-critical HAZ at a location having fine grain size and coarse M23C6 precipitates. Moreover, the grain structure of the inter-critical HAZ, which is a mixture of soft α and hard α’ grains, plays an important role in the stage of cavity evolution into a crack along the grain boundary. This is due to the heterogeneity of local strain between the two kinds of grains. By a synergistic effect of the strain concentration, the coarse precipitates and heterogeneous strain distribution among grains in the inter critical HAZ, facilitates the nucleation and growth of creep cavities, resulting in premature failure of welded joints.

Similar content being viewed by others

References

H. Cerjak and E. Letofsky, Conference Proceedings on Advanced Heat Resistance Steels for Power Generation, p.541, San Sebastian, Spain (1998).

J. M. Brear, A. Fairman, C. J. Middleton, and L. Polding, Key Eng. Mater. 171–174, 35 (2000).

C. J. Middleton, J. M. Brear, R. Munson, and R. Viswanathan: Proceeding of 3rd Conference on Advances in Materials Technology for Fossil Power Plants, (eds. R. Viswanathan, W. T. Bakker, and J. D. Parker), p.69, The Institute Materials, London (2001).

E. Letofsky, H. Cerjak, I. Papst, and P. Warbichler: Proceeding of 3rd Conference on Advances in Materials Technology for Fossil Power Plant, (eds. R. Viswanathan, W. T. Bakker and J. D. Parker), p.133, The Institute Materials, London (2001).

F. Masuyama, M. Matsui, and N. Komai, Key Eng. Mater. 171–174, 99 (2000).

M. Matsui, M. Tabuchi, T. Watanabe, K. Kubo, J. Kinugawa, and F. Abe, ISIJ International, 41, S126 (2001).

M. Tabuchi, T. Watanabe, K. Kubo, M. Matsui, J. Kinugawa, and F. Abe International J. Pressure Vessels Piping, 78, 779 (2001).

M. Tabuchi, M. Matsui, T. Watanabe, H. Hongo, K. Kubo, and F. Abe, Mater. Sci. Res. Int. 9, 23 (2003).

R. Viswanathan, Damage Mechanisms and Life Assessment of High Temperature Components, p.206, ASM International, Metals Park, Ohio (1989).

F. V. Ellis and R. Viswanathan, Review of Type IV Cracking in Piping Welds, p.125, Integrity of High Temperature Welds Professional Engineering Publishing Ltd. UK. (1998).

Y. Hasegawa, M. Ohgami, and Y. Okamura, Proceeding of 3rd Conference on Advances in Materials Technology for Fossil Power Plant, (eds. R. Viswanathan, W. T. Bakker and J. D. Parker), p.457, The Institute Materials, London (2001).

M. Tabuchi, T. Watanabe, K. Kubo, M. Matsui, J. Kinugawa, and F. Abe, Journal of the Society of Materials Science Japan, 50, 116 (2001).

S. K. Albert, M. Matsui, T. Watanabe, H. Hongo, K. Kubo, and M. Tabuchi ISIJ International, 42, 1497 (2002).

S. K. Albert, M. Matsui, T. Watanabe, H. Hongo, K. Kubo, and M. Tabuchi, International J. Pressure Vessels Piping, 80, 405 (2003).

K. Laha, K. S. Chandravathi, K. B. S. Rao, S. L. Mannan, and D. H. Sastry, Metall. Mater. Trans. A 32, 115 (2001).

M. Matsui, M. Tabuchi, T. Watanabe, K. Kubo, and F. Abe, Journal of the Society of Materials Science Japan, 52, 119 (2003).

A. Iseda, Y. Sawaragi, and K. Yoshikawa, Tetsu-to-Hagane (Translation: Journal of the Iron-Steel Institute of Japan), 77, 582 (1991).

J. S. Lee, K. Maruyama, I. Nonaka, and T. Ito, Proc. of 4th Int. Symposium on Risk, Economy and Safety, Failure Mechanism and Analysis (Failure 2004), pp.211–223, Cape Town, Republic of South Africa (2004).

K. Maruyama, K. Sawada, and J. Koike, ISIJ International, 41, 641 (2001).

K. Suzuki, S. Kumai, H. Kushima, K. Kimura, and F. Abe, Tetsu-to-Hagane (Translation: Journal of the Iron-Steel Institute of Japan), 86, 52 (2000).

J. Cermak, J. Ruzickova, and A. Pokorna, Scripta Materialia, 35, 441 (1996).

J. S. Lee and K. Maruyama, Proceeding of the Second International Conference on Advanced Structural Steels, Shanghai, 2, 838 (2004).

R. W. Evans and B. Wilshire, Creep of Metals and Alloys, p.19, The Institute of Metals, London (1985).

Y. M. Lee, S. I. Kwun, and Y. H. Chung, Met. Mater. Int. 20, 223 (2014).

Y. Shen, B. Ji, and X. Zhou, Met. Mater. Int. 20, 503 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.S., Maruyama, K. Mechanism of microstructural deterioration preceding type IV failure in weldment of Mod.9Cr-1Mo steel. Met. Mater. Int. 21, 639–645 (2015). https://doi.org/10.1007/s12540-015-4569-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4569-5