Abstract

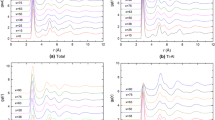

Atomic size differences between constituting elements and the heat of mixing are key factors in designing a metallic glass system. In this study, the effects of atomic size differences and the heat of mixing on the glass-forming ability and the local structure of metallic glasses were studied via molecular dynamic simulations of an ideal system known as the Lennard-Jones embedded-atom method model. The atomic size difference and the heat of mixing of the system were varied by means of the Lennard-Jones parameters. The glass transition behavior was characterized based on the chemical short-range order and by a Voronoi analysis. Our simulations lead to optimized windows of atomic size differences and heat of mixing parameters for metallic glass-forming of the model system. Both a greater negative heat of mixing and a larger atomic size difference are necessary for the enhancement of the glass-forming ability.

Similar content being viewed by others

References

A. Inoue, Mater. Trans. JIM. 36, 866 (1995).

J. H. Li, Y. Dai, Y. Y. Cui, and B. X. Liu, Mater. Sci. Eng. R: Rep. 72, 1 (2011).

O. N. Senkov and D. B. Miracle, Mater. Res. Bull. 36, 2183 (2001).

Z. P. Lu, C. T. Liu, and Y. D. Dong, J. Non-Cryst. Solids. 341, 93 (2004).

J. Saida, M. Matsushita, and A. Inoue, Mater. Trans. 43, 1937 (2002).

M. Shimono and H. Onodera, Mater. Trans. 46, 2830 (2005).

J. J. Lee, K. W. Park, D. H. Kim, and E. Fleury, Korean J. Met. Mater. 49, 930 (2011).

H.-S. Kim, K.-S. Yoon, and J.-C. Lee, Korean J. Met. Mater. 49, 823 (2011).

V. V. Hoang, Physica B: Condensed Matter 406, 3653 (2011).

M. Shimono and H. Onodera, Mater. Trans. 45, 1163 (2004).

M. Shimono and H. Onodera, Scripta Mater. 44, 1595 (2001).

J. M. Delaye and Y. Limoge, J. Non-Cryst. Solids 156–158, 982 (1993).

P. M. Derlet, R. Maaß, and J. F. Löffler, Eur. Phys. J. B 85, 148 (2012).

D. Wang, Y. Li, B. B. Sun, M. L. Sui, K. Lu, and E. Ma, Appl. Phys. Lett. 84, 4029 (2004).

D. Xu, B. Lohwongwatana, G. Duan, W. L. Johnson, and C. Garland, Acta Mater. 52, 2621 (2004).

M. B. Tang, D.-Q. Zhao, M.-X. Pan, and W.-H. Wang, Chinese Phys. Lett. 21, 901 (2004).

N. Mattern, P. Jóvári, I. Kaban, S. Gruner, A. Elsner, V. Kokotin, H. Franz, B. Beuneu, and J. Eckert, J. Alloys Comp. 485, 163 (2009).

A. E. Lagogianni, G. Almyras, Ch. E. Lekka, D. G. Papageorgiou, and G. A. Evangelakis, J. Alloys Comp. 483, 658 (2009).

G. A. Almyras, Ch. E. Lekka, N. Mattern, and G. A. Evangelakis, Scripta Mater. 62, 33 (2010).

L. Yang, S. Yin, X. D. Wang, Q. P. Cao, J. Z. Jiang, K. Saksl, and H. Franz, J. Appl. Phys. 102, 083512 (2007).

D. Holland-Moritz, S. Stüber, H. Hartmann, T. Unruh, T. Hansen, and A. Meyer, Phys. Rev. B 79, 064204 (2009).

E. W. Iparraguirre, J. Sietsma, and B. J. Thijsse, J. Non-Cryst. Solids 156, 969 (1993).

H. Ruppersberg, D. Lee, and C. N. J. Wagner, J. Phys. F-Met. Phys. 10, 1645 (1980).

L. Pusztai and E. Svab, J. Non-Cryst. Solids 156, 973 (1993).

E. Svab, F. Forgács, F. Hajdu, N. Kroó, and J. Takács, J. Non-Cryst. Solids 46, 125 (1981).

M. Sakata, N. Cowlam, and H. A. Davies, J. Phys. F-Met. Phys. 11, L157 (1981).

L. Zhang, Y.-Q. Cheng, A.-J. Cao, J. Xu, and E. Ma, Acta Mater. 57, 1154 (2009).

T. Takagi, T. Ohkubo, Y. Hirotsu, B. S. Murty, K. Hono, and D. Shindo, Appl. Phys. Lett. 79, 485 (2001).

D. J. Sordelet, R. T. Ott, M. Z. Li, S. Y. Wang, C. Z. Wang, M. F. Besser, A. C. Y. Liu, and M. J. Kramer, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 39A, 1908 (2008).

Y. Q. Cheng and E. Ma, Prog. Mater. Sci. 56, 379 (2011).

Y. Q. Cheng, E. Ma, and H. W. Sheng, PRL 102, 245501 (2009).

Y. Q. Cheng, E. Ma, and H. W. Sheng, Appl. Phys. Lett. 93, 111913 (2008).

S. G. Srinivasan and M. I. Baskes, Proc. R. Soc., Lond., Ser. A 460, 1649 (2004).

A. Oluwajobi and X. Chen, Key Eng. Mater. 535–536, 330 (2013).

R. K. Rajgarhia, D. E. Spearot, and A. Saxena, Comp. Mater. Sci. 44, 1258 (2009).

R. B. Godiksen, Z. T. Traut, M. Upmanyu, S. Schmidt, and D. J. Jensen, Mater. Sci. Forum 558–559, 1081 (2007).

X.-L. Ma and W. Yang, Nanotechnology 15, 449 (2004).

Z. Guo and W. Yang, Int. J. Mech. Sci. 48, 145 (2006).

B. Ao, X. Wang, W. Hu, and J. Yang, Phys. Status Solidi B 245, 1493 (2008).

B. Ao, X. Wang, W. Hu, and J. Yang, J. Nucl. Mater. 385, 75 (2009).

Y. Yonekawa and K.-I. Saitoh, Zairyo/Journal of the Society of Materials Science, 59, 624 (2010).

S. Davis, C. Loyola, F. González, and J. Peralta, Comput. Phys. Commun. 181, 2126 (2010).

H. Kang Y. Zhang, and M. Yang, Appl. Phys. A 103, 1001 (2011).

H. Tsuzuki, P. S. Branicio, and J. P. Rino, Comput. Phys. Commun. 177, 518 (2007).

A. Takeuchi and A. Inoue, Mater. Trans. 46, 2817 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yun, Y.S., Nam, H.S., Cha, P.R. et al. Effects of atomic size difference and heat of mixing parameters on the local structure of a model metallic glass system. Met. Mater. Int. 20, 105–111 (2014). https://doi.org/10.1007/s12540-013-6013-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-6013-z