Abstract

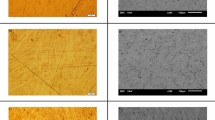

The effect of Ti addition on the microstructure, martensitic transformation, magnetic and mechanical properties of polycrystalline Ni51Fe22−x Ga27Ti x (x=0, 2 and 4) ferromagnetic shape memory alloy was investigated by scanning electron microscope, differential scanning calorimetry and X-ray diffraction. The results showed that the martensitic transformation temperature increases monotonously with the increase of fraction of Ti substitution for Fe. The increase in the martensite transformation temperatures should be related to the change of the electron concentration after the addition of Ti to Ni51Fe22−x Ga27Ti x alloys. According to the results of X-ray diffraction and magnetic properties, Ti has significant effect the structure of Ni51Fe22-x Ga27Ti x . Adding of 4 at% Ti altered the structure of the matrix from five-layered tetragonal martensite of Ni51Fe22Ga27 and Ni51Fe20Ga27Ti2 alloys to non-modulated tetragonal martensite. Magnetic properties proved that the alloy transits from ferromagnetic, five-layered tetragonal martensite, to paramagnetic, non-modulated martensite structure, with increasing Ti content to 4 at.%. Saturation magnetization, remnant magnetization and coercivity of the alloy were significantly influenced by Ti additions. Hardness values of Ni51Fe22Ga27 increased by the addition of Ti.

Similar content being viewed by others

References

F. Ahmad Khalid, and S. Zameer Abbas, Mater. Charct. 62, 1134 (2011).

K. Ullakko, J. K. Huang, C. Kantner, R. C. O’Handley, and V. V. Kokorin, Appl. Phys. Lett. 69, 1966 (1996).

S. J. Murray, M. Marioni, S. M. Allen, R. C. O’Handley, and T. A. Lograsso, Appl. Phys. Lett. 77, 886 (2000).

R. D. James, M. Wutting, Philo. Mag. A. 77, 1273 (1998).

T. Kakeshita, T. Takeuchi, T. Fukuda, T. Saburi, R. Oshima, S. Muto, and K. Kisho, Mater. Trans. JIM 41, 882 (2002).

V. A. Chernenko, J. Pons, E. Casari, and A. E. Perekos, Mater. Sci. Eng. A 378, 357 (2004).

Y. Q. Huo, J. Alloys Compd. 485, 300 (2009).

A. Fujita, K. Fukamichi, F. Gejima, R. Kainuma, and K. Ishida, Appl. Phys. Lett. 77, 3054 (2000).

K. Oikawa, T. Ota, Y. Sutou, T. Ohmori, R. Kainuma, and K. Ishida, Mater. Trans. 43, 2360 (2002).

K. Oikawa, T. Ota, F. Gejima, T. Ohmori, R. Kainuma, and K. Ishida, Mater. Trans. 42, 2471 (2001).

H. E. Karaca, I. Karman, D. C. Lagoudas, H. J. Maier, and Y. I. Chumlyakov, Scripta Mater. 49, 831 (2003).

Y. Q. Huo and J. G. Li, J. Alloys Compd. 480, 230 (2009).

K. Oikawa, T. Ota, Y. Sutou, T. Ohmori, R. Kainuma, and K. Ishida, Mater. Trans. 43, 2360 (2002).

Z. H. Liu, M. Zhang, Y. T. Cui, Y. Q. Zhou, W. H. Wang, G. H. Wu, X. X. Zhang, and G. Xiao, Appl. Phys. Lett. 83, 424 (2003).

J. Liu, N. Scheerbaum, D. Hinz, and O. Gutfleisch, Acta Mater. 56, 3177 (2008).

A. Dannenberg, M. Siewert, M. E. Gruner, M. Wuttig, and P. Entel, Physics Procedia 10, 144 (2010).

J. Liu, H. X. Zheng, M. X. Xia, Y. L. Huang, and J. G. Li, Scripta Mater. 52, 935 (2005).

H. X. Zheng, J. Liu, M. X. Xia, and J. G. Li, J. Alloys Compd. 387, 265 (2005).

J. Liu, H. X. Zheng, M. X. Xia, and J. G. Li, Scripta Mater. 52, 955 (2005).

H. Moritoa, K. Oikawa, A. Fujita, K. Fukamichi, R. Kainuma, and K. Ishida, Scripta Mater. 53, 1237 (2005).

H. Morito, K. Oikawa, A. Fujita, K. Fukamichi, R. Kainuma, K. Ishida, and T. Takagi, J. Magn. Mater. 290, 850 (2005).

H. E. Karaca, Ph. D. Thesis, pp.88–102, Kentucky University, Kentucky (2007).

K. Rolfs, M. Chmielus, J. M. Guldbakke, R. C. Wimpory, A. Raatz, W. Petry, P. Müllner, and R. Scheider, Advanced Engineering Materials 14/8, 614 (2012).

H. J. Yu, X. D. Jiang, H. Fu, and X. T. Zu, J. Alloys Compd. 490, 326 (2010).

H. J. Yu, X. D. Jiang, H. Fu, and X. T. Zu, J. Alloys Compd. 490, 628 (2009).

H. X. Zheng, M. X. Xia, J. Liu, Y. L. Huang, and J. G. Li, J. Alloys Compd. 385, 144 (2004).

J. Sui, Z. Gao, H. Yu, Z. Zhang, and W. Cai, Scripta Mater. 59, 874 (2008).

R. L. Wang, J. B. Yan, H. B. Xiao, L. S. Xu, V. V. Marchenkov, L. F. Xu, and C. P. Yang, J. Alloys Compd. 509, 6834 (2011).

M. Chmielus, C. Witherspoon, K. Ullakko, P. Müllner, and R. Schneider, Acta Mater. 59, 2948 (2011).

S. Aich, S. Das, I. A. Al-Omari, P. Alagarsamy, S. G. Chowdhury, M. hakraborty, J. E. Shield, and D. J. Sellmyer, J. Appl. Phys. 105, 07A943 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Bagoury, N., Mohsen, Q., Kaseem, M.A. et al. Influence of Ti additions on martensitic transformation and magnetic properties of cast Ni51Fe22−xGa27Tix shape memory alloys. Met. Mater. Int. 19, 991–997 (2013). https://doi.org/10.1007/s12540-013-5011-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5011-5