Abstract

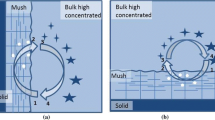

During melt treatment by cooling sloping plate, laminar flow and turbulent flow exist on sloping plate surface commonly. The thickness of velocity boundary layer and the critical transfer distance from laminar flow to turbulent flow increase with the decrease of initial flow velocity. The thickness of temperature boundary layer increases with the increment of flow distance and the decrease of initial flow velocity. The melt cooling rate and melt thickness have an inverse proportion relationship. The melt cooling rate of cooling sloping plate process can reach 102–103 K/s and belongs to meta-rapid solidification scope. Uniform solute field and high cooling rate can lead to eruptive nucleation. In addition, a large quantity of heterogonous nuclei appears on the sloping plate surface, and vibrating flow can enable heterogonous nucleus to escape off the plate, which leads to nucleus multiplication. Under relative uniform solute field and high cooling rate, some grains can keep stable growth surface, go on growing with the round surface and finally maintain their globular structure. However, there are always some grains that grow along a certain preferred direction, but under vibrating flow their dendritic arms break and transform into near spherical structure.

Similar content being viewed by others

References

H. Kaufmann, A. Mundl, P. J. Uggowitzer, R. Potzinger, and N. Ishibashi, Die Cast. Eng. 46, 4 (2002).

T. Motegi, Int. J. Mater. Prod. Technol. 2, 468 (2001).

Haga T, J. Mater. Process. Technol. 130, 558 (2002).

S. M. Yang and W. Q. Tao, Heat Transfer, pp. 4–22, Higher Education Press, China (2006).

E. C. Legoretta, H. V. Atkinson, and H. Jones, J. Mater. Sci. 43, 5448 (2008).

H. Han, S. F. Liu, L. G. Kang, and L. Y. Liu, J. Wuhan Univ. Technol. Mater. Sci. Ed. 23, 194 (2008).

R. G. Guan, Z. Y. Zhao, H. Zhang, C. Lian, C. S. Lee, and C. M. Liu, J. Mater. Process. Technol. 212, 1430 (2012).

Q. Z. Le and J. Z. Cui, The Basic Principles of Transmission, pp. 47–105, Metallurgical Industry Press, China (2005).

R. C. Ruhl, Mater. Sci. Eng. 1, 313 (1967).

H. Mehrara, M. Nili-Ahmadabadi, B. Heidarian, S. Ashouri, and J. Ghiasinejad, Diffus. Defect. Data Part. B 141–143, 785 (2008).

R. Canyook, S. Petsut, S. Wisutmethangoon, M. C. Flemings, and J. Wannasin, Trans. Nonferrous Met. Soc. China 20, 1649 (2010).

S. Ji, Z. Fan, and M. J. Bevis, Mater. Sci. Eng. A 299, 210 (2001).

J. C. van Dam and F. H. Mischgofsky, J. Mater. Sci. 17, 989 (1982).

L. Nastac and D. M. Stefannescu, Metall. Mater. Trans. A 27, 4061 (1996).

Z. Fan, Int. Mater. Rev. 47, 49 (2002).

R. G. Guan, S. C. Wang, J. L. Wen, and X. H. Liu, Mater. Sci. Technol. 22, 706 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guan, R.G., Zhao, Z.Y., Chao, R.Z. et al. Boundary layer and cooling rate and microstructure formation on the cooling sloping plate. Met. Mater. Int. 19, 949–957 (2013). https://doi.org/10.1007/s12540-013-5007-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5007-1