Abstract

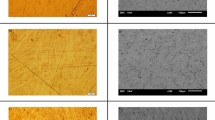

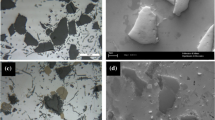

In recent years, the processing of metallic materials via severe plastic deformation has been widely applied to manufacture bulk specimens of ultrafine grained/nanocrystalline structures. In this study, bulk nanocomposites of carbon nanotube-reinforced Cu were manufactured by consolidation of mixtures of coarse grained Cu powders and CNTs of two volume fractions (5 vol% and 10 vol%) using high-pressure torsion, a typical SPD method. The effects of CNT reinforcements on the microstructural evolution of the Cu matrix were investigated using electron backscatter diffraction and scanning/transmission electron microscopy; the results showed that the Cu matrix grain size was reduced to ∼114 nm, and the CNTs were well dispersed in the matrix. Due to the effect of the UFG Cu and CNTs, the tensile strength (350 MPa) of the nanocomposite was higher than that (190 MPa) of Cu processed by the powder HPT process without CNTs. However, the Cu-CNT 10 vol% indicated a decreased tensile strength due to an increased interface area between the matrix and CNTs at high volume fractions of CNTs.

Similar content being viewed by others

References

H. W. Kroto, J. R. Heath, S. C. O’Brien, R. F. Curl, and R. E. Smalley, Nature 318, 162 (1985).

S. Iijima, Nature 354, 56 (1991).

M. M. J. Treacy, T. W. Ebbesen, and J. M. Gibson, Nature 381, 678 (1996).

E. W. Wong, P. E. Sheehan, and C. M. Lieber, Science 277, 1971 (1997).

A. A. Mamedov, N. A. Kotov, M. Prato, D. M. Guldi, J. P. Wicksted, and A. Hirsch, Nat. Mater. 1, 190 (2002).

E. T. Thostenson, Z. Ren, and T.-W. Chou, Compos. Sci. Technol. 61, 1899 (2001).

M. Y. Song, Y. J. Kwak, B. -S. Lee, H. R. Park, and B. -G. Kim, Korean J. Met. Mater. 49, 989 (2011).

R. Z. Valiev, R. K. Islamgaliev, and I. V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000).

R. Z. Valiev, Y. Estrin, Z. Horita, T. G. Langdon, M. J. Zehetbauer, and Y. T. Zhu, JOM 58, 33 (2006).

Z. Horita, D. J. Smith, M. Furukawa, M. Nemoto, R. Z. Valiev, and T. G. Langdon, J. Mater. Res. 11, 1880 (1996).

A. P. Zhilyaev and T. G. Langdon, Prog. Mater. Sci. 53, 893 (2008).

A. P. Zhilyaev, G. V. Nurislamova, B. K. Kim, M. D. Baró, J. A. Szpunar, and T. G. Langdon, Acta Mater. 51, 753 (2003).

V. V. Stolyarov, Y. T. Zhu, T. C. Lowe, R. K. Islamgaliev, and R. Z. Valiev, Mater. Sci. Eng. A 282, 78 (2000).

I. V. Alexandrov, K. Zhang, A. R. Kilmametov, K. Lu, and R. Z. Valiev, Mater. Sci. Eng. A 234-236, 331 (1997).

E. Y. Gutmanas, Prog. Mater. Sci. 34, 261 (1990).

T. Tokunaga, K. Kaneko, K. Sato, and Z. Horita, Scripta Mater. 58, 735 (2008).

H. Li, A. Misra, Y. Zhu, Z. Horita, C. C. Koch, and T. G. Holesinger, Mater. Sci. Eng. A 523, 60 (2009).

H. Li, A. Misra, Z. Horita, C. C. Koch, N. A. Mara, P. O. Dickerson, and Y. Zhu, Appl. Phys. Lett. 95, (2009).

S. H. Joo, S. C. Yoon, C. S. Lee, D. H. Nam, S. H. Hong, and H. S. Kim, J. Mater. Sci. 45, 4652 (2010).

Y. Estrin, Dislocation-Density-Related Constitutive Modeling, in Unified Constitutive Laws of Plastic Deformation, pp. 69–106, Academic Press, New York (1996).

DEFORM Software, Scientific Forming Technologies Corp., Columbus, OH (2007).

R. B. Figueiredo, P. R. Cetlin, and T. G. Langdon, Mater. Sci. Eng. A 528, 8198 (2011).

D. J. Lee, E. Y. Yoon, L. J. Park, and H. S. Kim, Scripta Mater. 67, 384 (2012).

X. H. An, S. D. Wu, Z. F. Zhang, R. B. Figueiredo, N. Gao, and T. G. Langdon, Scripta Mater. 63, 560 (2010).

Z. Horita and T. G. Langdon, Mater. Sci. Eng. A 410–411, 422 (2005).

N. Lugo, N. Llorca, J. M. Cabrera, and Z. Horita, Mater. Sci. Eng. A 477, 366 (2008).

E. Y. Yoon, D. J. Lee, D. H. Ahn, E. S. Lee, and H. S. Kim, J. Mater. Sci. 47, 7770 (2012).

T. Tokunaga, K. Kaneko, and Z. Horita, Mater. Sci. Eng. A 490, 300 (2008).

P. Jenei, E. Y. Yoon, J. Gubicza, H. S. Kim, J. L. Lábár, and T. Ungár, Mater. Sci. Eng. A 528, 4690 (2011).

D. B. Williams and C. B. Carter, Transmission Electron Microscopy: Imaging, Plenum Press (1996).

Y. Feng, H. L. Yuan, and M. Zhang, Mater. Charact. 55, 211 (2005).

S. M. L. Nai, J. Wei, and M. Gupta, Mater. Sci. Eng. A 423, 166 (2006).

S. R. Dong, J. P. Tu, and X. B. Zhang, Mater. Sci. Eng. A 313, 83 (2001).

K. T. Kim, S. I. Cha, and S. H. Hong, Mater. Sci. Eng. A 430, 27 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, E.Y., Lee, D.J., Park, B. et al. Grain refinement and tensile strength of carbon nanotube-reinforced Cu matrix nanocomposites processed by high-pressure torsion. Met. Mater. Int. 19, 927–932 (2013). https://doi.org/10.1007/s12540-013-5004-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5004-4