Abstract

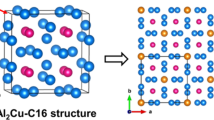

Aluminum-copper multilayered composites were synthesized at ambient temperature from a layered array of individual elemental aluminum and copper foils by up to 10 cycles of accumulative roll bonding and folding (ARBF). Well-bonded sheet materials were successfully obtained with an initial cycle reduction of 50%. The microstructural development during the ARBF process was investigated by optical microscopy and scanning electron microscopy. After 10 cycles of ARBF, the crystallite sizes of Al and Cu, calculated by the Rietveld method, were 70 nm and 50 nm, respectively. WDS analysis revealed that by increasing the number of ARBF cycles, diffusion of Cu atoms was increased.

Similar content being viewed by others

References

R. Z. Valiev, N. A. Krasilinikov, and N. K. Tsenev, Mater. Sci. Eng. A 137, 35 (1991).

R. Z. Valiev, A. V. Korznikov, and R. R. Mulyukov, Mater. Sci. Eng. A 168, 141 (1993).

Z. Horita, M. Furukawa, N. Nemoto, A. J. Barnes, and T. G. Longdon, J. Acta. Mater. 48, 3633 (2000).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, J. Acta. Mater. 47, 579 (1999).

R. Z. Valiev and T. G. Longdon, J. Prog. in Mater. Sci. 51, 881 (2006).

A. P. Zhilyaev, G. V. Nurislamova, B. K. Kim, M. D. Baro, and J. A. Szpunar, J. Acta. Mater. 51, 753 (2003).

G. P. Dinda, H. Rösner, and G. Wild, J. Mater. Sci. Eng. A 410–411, 328 (2005).

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R. G. Hong, J. Scr. Mater. 39, 1221 (1998).

G. Wilde, H. Sieber, and J. H. Perepezko, J. Scr. Mater. 40, 779 (1999).

G. P. Dinda, H. Rosner, and G. Wilde, J. Scr. Mater. 52, 577 (2005).

M. Eizadjou, A. K. Talachi, H. D. Manesh, H. S. Shakur, and K. Janghorban, J. Composites. Sci. Tech. 68, 2003 (2008).

M. C. Chen, H. C. Hsieh, and W. Wu, J. Alloys. Comp. 416, 169 (2006).

A. Mozaffari, H. D. Manesh, and K. Janghorban, J. Alloys. Comp. 489, 103 (2010).

F. Kavarana, K. Ravichandran, and S. Sahay, Scr. Mater. 42, 947 (2000).

H. Sieber, G. Wilde, and J. Perepezko, J. Non-Cryst. Solids 250–252, 611 (1999).

S. Kikuchi, H. Kuwahara, N. Mazaki, S. Urai, and H. Miyamura, Mater. Sci. Eng A 234–236, 1114 (1997).

K. Yasuna, M. Terauchi, A. Otsuki, K. N. Ishihara, and P. H. Shingu, Mater. Sci. Eng. A 285, 412 (2000).

G. Min, J. M. Lee, and S. B. Kang, Mater. Lett. 60, 3255 (2006).

A. Chanda and M. De, Alloys. Comp. 313, 104 (2000).

H. Pal, A. Chanda, and M. De, Alloys. Comp. 278, 209 (1998).

M. Eizadjou, A. K. Talachi, H. Daneshmanesh, H. S. Shahabi, and K. Janghorban, Comp. Sci. Tech. 68, 2003 (2008).

N. Tsuji, Y. Saito, S. H. Lee, and Y. Minamino, Adv. Eng. Mater. 5, 338 (2003).

Y. H. Jang, S. S. Kim, S. Z. Han, C. Y. Lim, and C. J. Kim, Scr. Mater. 52, 21 (2005).

S. Z. Han, C. Lim, C. J. Kim, and S. Kim, Mater. Sci. Forum 475, 3497 (2005).

M. Shaarbaf and M. R. Toroghinejad, Mater. Sci. Eng. A 473, 28 (2008).

H. Pirgazi, A. Akbarzadeh, R. Petrov, and L. Kestens, Mater. Sci. Eng. A 497, 132 (2008).

C. Kwan, Z. Wang, and S. B. Kang, Mater. Sci. Eng. A 480, 148 (2008).

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R. G. Hong, Scr. Mater. 39, 1221 (1998).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khademzadeh, S., Toroghinejad, M.R. & Ashrafizadeh, F. Structural evolution and interdiffusion in Al/Cu nanocomposites produced by a novel manufacturing process. Met. Mater. Int. 18, 1049–1054 (2012). https://doi.org/10.1007/s12540-012-6019-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-6019-y