Abstract

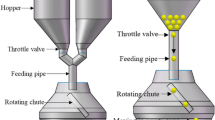

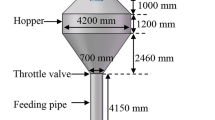

Process efficiency in the blast furnace is influenced by the gas flow pattern, which is dictated by the burden profile. Therefore, it is important to control the burden distribution so as to achieve reasonable gas flow in the blast furnace operation. Additionally, the charging pattern selection is important as it affects the burden trajectory and stock profile. For analysis of the burden distribution, a new analysis model was developed by use of the spreadsheet program, Microsoft® Office Excel, based on visual basic. This model is composed of the falling burden trajectory and a stock model. The burden trajectory is determined by the burden type, batch weight, rotating velocity of the chute, tilting angle, and friction coefficient. After falling, stock lines are formed by the angle of repose, which is affected by the burden trajectory and the falling velocity. The mathematical formulas for developing this model were modified by a scaled model experiment and DEM simulation.

Similar content being viewed by others

References

R. Goffin, Blast Furnace Burden Distribution-Principles and Practices, -1, Iron and Steel Society, Nashville (1995).

Y. Okuno, K. Kunitomo, T. Irita, and S. Matsuzaki, Tetsuto-Hagané 72, 783 (1986).

Y. Okuno, S. Matsuzaki, K. Kunitomo, M. Isoyama, and Y. Kusano, Tetsu-to-Hagané 73, 91 (1987).

T. Inada, Y. Kajiwara, and T. Tanaka, 49 th Ironmak. Conf. Proc., p. 263, Iron and Steel Society, Warrendale, PA (1990).

K. Okimoto, S. Inaba, R. Ono, and M. Takada. Tetsu-to-Hagané 71, A9 (1985).

J. J. Povermo, Blast Furnace Burden Distribution-Principles and Practices, p. 1, Iron and Steel Society (1995).

P. L. Hooey, A. Boden, C. Wang, C. Grip, and B. Jansson, ISIJ Int. 50, 924 (2010).

P. R. Austin, H. Nogami, and J. Yagi, ISIJ Int. 37, 458 (1997).

P. R. Austin, H. Nogami, and J. Yagi, ISIJ Int. 37, 748 (1997).

P. R. Austin, H. Nogami, and J. Yagi, ISIJ Int. 38, 10 (1998).

J. A. Castro, H. Nogami, and J. Yagi, ISIJ Int. 42, 44 (2002).

T. Sugiyama and M. Sugata, Seitetsu Kenkyu 34 (1987).

K. Takatani, T. Inada, and Y. Ujisawa, ISIJ Int. 39, 15 (1999).

S. Natsui, S. Ueda, M. Oikawa, Z. Fan, J. Kano, R. Inoue, and T. Ariyama, ISIJ Int. 49, 1308 (2009).

Robert de Levie, Advanced Excel for Scientific Data Analysis, Oxford University Press (2004).

D. M. Bourg, Excel Scientific and Engineering Cookbook, O’Reilly (2006).

V. R. Radhakrishnan and K. M. Ram, J. Proc. Control. 11, 565 (2001).

N. Standish, Principles of Burdening and Bell-Less Charging, Nimaroo Publishers, Wolloongong, Australia (1989).

T. Nagai, Mc Master Symposium on Optimum Burden Distribution in Blast Furnace, 13.1 (1978).

S. K. Jung, C. Y. Beak, and W. S. Chung, J. Kor. Inst. Met. & Mater. 39, 1171 (2001).

P. A. Cundall and O. D. L. Strackm, Geotechnique 29, 47 (1979).

S. Ueda, S. Natsui, H. Nogami, J. Yagi, and T. Ariyama, ISIJ Int. 50, 914 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, JI., Jung, HJ., Jo, MK. et al. Mathematical modeling of the burden distribution in the blast furnace shaft. Met. Mater. Int. 17, 485–496 (2011). https://doi.org/10.1007/s12540-011-0629-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-011-0629-7