Abstract

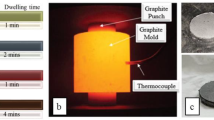

The formation, microstructure and properties of high-density TiN/Ti5Si3 ceramic composites created by the pyrolysis of preceramic polymer with filler were investigated. Methylpolysiloxane was mixed with TiH2 as filler and ceramic composites prepared by pyrolysis at 1200°C to 1600°C under N2, Ar and vacuum were studied. When a specimen with 70 vol.% TiH2 was pyrolyzed up to 1600°C in a vacuum after a preheat treatment at 850°C in a N2 atmosphere and subsequently heat-treated at 1600°C for 1 h under Ar at a pressure of 2 MPa, a ceramic composite with full density was obtained. The microstructure of the ceramic composite was composed of TiN and Ti5Si3 phases. Under specific pyrolysis conditions, a ceramic composite with a density of 99.2 TD%, a Vickers hardness of 18 GPa, a fracture toughness of 3.5 MPam1/2, a flexural strength of 270 MPa and a electrical conductivity of 6200 ohm−1·cm−1 was obtained.

Similar content being viewed by others

References

H. Kuwahara, N. Mazaki, M. Takahashi, T. Watanabe, X. Yang, and T. Aizawa, Mater. Sci. Eng. A 319–321, 687 (2001).

R. M. Marin-Ayral, C. Pascal, F. Martinez, and J. C. Tedenac, J. Eur. Ceram. Soc. 20, 2679 (2000).

D. P. Thomson, Nitrides, Vol. 3 (eds., D. Bloor, R. J. Brook, M. C. Flemings, and S. Mahajan), p. 1760–1763, The Encyclopedia of Advanced Materials, Pergamon (1995).

T. Graziani and A. Bellosi, J. Mater. Sci. Lett. 14, 1078 (1995).

S. Yajima, J. Hayashi, M. Omori, and K. Okamura, Nature 261, 683 (1976).

R. W. Rice, Am. Ceram. Soc. Bull. 62, 889 (1983).

B. E. Walker, R. W. Rice, P. F. Becher, B. A. Bender, and W. S. Coblenz, Am. Ceram. Soc. Bull. 62, 916 (1983).

K. J. Wynne and R. W. Rice, Annu. Rev. Mater. Sci. 14, 297 (1984).

P. Greil and M. Seibold, Active-Filler-Controlled Pyrolysis (AFCOP) — A Novel Fabrication Route to Ceramic Composite Materials: Ceramic Transaction, Vol. 19 (ed., M. D. Sacks), p. 43, American Ceramic Society, Westerville, OH (1991).

S. H. Yu, R. E. Riman, and S. C. Danforth, J. Am. Ceram. Soc. 78, 1818 (1995).

P. Greil, J. Am. Ceram. Soc. 78, 835 (1995).

C. K. Narula, B. G. Demczyk, P. Czubarow, and D. Seyferth, J. Am. Ceram. Soc. 78, 1247 (1995).

O. Lichtenberger, E. Pipprl, J. Woltersdorf, and R. Riedel, Mater. Chem. Phys. 81, 195 (2003).

D. Seyferth and G. Mignani, J. Mater. Sci. Lett. 7, 487 (1998).

A. Kaindl, W. Lehner, P. Greil, and D. J. Kim, Mater. Sci. Eng. A 260, 101 (1999).

I. Barin, Thermochemical Data of Pure Substance, VCH, Weinhein (1989).

S. J. Kang, Sintering, p.63–68, Elsevier (2005).

J. Li, D. Jiang, and S. Tan, J. Eur. Ceram. Soc. 22, 551 (2002).

J. F. Shackelford, W. Alexander, CRC Material Science and Engineering Handbook, p. 956, CRC Press (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, B.S., Hong, S.J. & Kim, D.J. Formation of high-density TiN/Ti5Si3 ceramic composites using preceramic polymer. Met. Mater. Int. 16, 565–568 (2010). https://doi.org/10.1007/s12540-010-0807-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-010-0807-z