Abstract

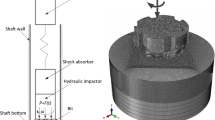

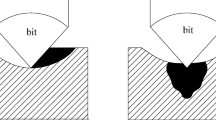

Percussion drilling is believed to be an efficient way to enhance the drilling performance, compared with the conventional drilling in deep wells, which could be achieved by applying impact loads above the drill bit. The finite simulation is an efficient method to predict the drilling performance when the drill bit interacts with rocks. In contrast, as results of finite element technology limitation, the conventional way is to apply the displacement or velocity boundary conditions on the bit; however, this is completely different from the real field drilling process. Therefore, in this paper, a 3-D rock-bit physical model is presented to simulate the practical percussion drilling under various types of loads; at the same time, experiment was conducted to validate the effectiveness of the rock-bit model. The results demonstrated that the drilling performance with the rectangular and sinusoidal loads was promoted than the other types of load, and rate of penetration (ROP) increases with increasing of the amplitude of dynamic load, which could provide the theoretical guidance to the down-the-hole drilling tool design, thereby proving a quite efficient and lower cost drilling in the exploration of hard formations.

Similar content being viewed by others

Abbreviations

- M-C:

-

Mohr–Coulomb

- D-P:

-

Drucker–Prager

- K:

-

Flow stress ratio

- φ :

-

Angle of friction (M-C)

- c:

-

Cohension

- β :

-

Angle of friction (D-P)

- f :

-

Drucker–Prager criteria

- I 1 :

-

First invariant of stress tensor

- J 2 :

-

Second invariant of stress partial tensor

- δ c :

-

Compression yield stress

- ROP:

-

Rate of penetration

- WOB:

-

Weight on bit

- RPM:

-

Revolution per minute

References

An W, Teng X, Yin D, et al (2012) Complicated drilling in extremely thick ultra-deep salt formation in Tarim-case of KeShen Well 7. IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition. Society of Petroleum Engineers

Gray KE, Armstrong F, Gatlin C (1962) Two-dimensional study of rock breakage in drag-bit drilling at atmospheric pressure. J Pet Technol 14:93–98

Guarin P, Arnold H, Harpst W, et al (1949) Rotary percussion drilling. Drilling and Production Practice. American Petroleum Institute

Han G, Bruno M, Dusseault MB (2005) Dynamically modelling rock failure in percussion drilling. Alaska Rocks 2005, The 40th US Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Han G, Bruno MS, Dusseault MB (2006) 3D simulation of rock breakage with air hammers in gas-well drilling. SPE Gas Technology Symposium. Society of Petroleum Engineers

Jin J-f, Li X-b, Wang G-s et al (2012) Failure modes and mechanisms of sandstone under cyclic impact loadings. J Cent South Univ (Science and Technology) 4:042

Kuang Y, Peng Y, Zhang Y (2015) Numerical simulation and experiment on rock breaking of PDC bits. China Petroleum Machinery

Li X-B, Gu D-S (1994) Energy dissipation of rock under impluse loading with different waveforms [J]. Expl Shock Waves 14:129–139

Lundberg B (1973a) Energy transfer in percussive rock destruction—II: supplement on hammer drilling. Int J Rock Mech Min Sci Geomech Abstr. Elsevier:401–419

Lundberg B (1973b) Energy transfer in percussive rock destruction—III: stress wave transmission through joints. Int J Rock Mech Min Sci Geomech Abstr. Elsevier:421–435

Lundberg B (1982) Microcomputer simulation of stress wave energy transfer to rock in percussive drilling. Int J Rock Mech Min Sci Geomech Abstr. Elsevier:229–239

Lundberg B, Okrouhlik M (2006) Efficiency of a percussive rock drilling process with consideration of wave energy radiation into the rock. Int J Impact Eng 32:1573–1583

Ma D, Zhou D, Deng R (1995) The computer simulation of the interaction between roller bit and rock. International Meeting on Petroleum Engineering. Society of Petroleum Engineers

Melamed Y, Kiselev A, Gelfgat M, Dreesen D, Blacic J (2000) Hydraulic hammer drilling technology: developments and capabilities. J Energy Resour Technol 122:1–7

Reddish D, Stace L, Vanichkobchinda P et al (2005) Numerical simulation of the dynamic impact breakage testing of rock. Int J Rock Mech Min Sci 42:167–176

Samuel GR (1996) Percussion drilling... Is it a lost technique? A review. Permian Basin Oil and Gas Recovery Conference. Society of Petroleum Engineers

Sazid M, Singh T (2013) Two-dimensional dynamic finite element simulation of rock blasting. Arab J Geosci 6:3703–3708

Shan R, Yang Y, Zhao T (1995) Study on incident wave shape and penetrative efficiency of a percussive penetrative system. Explosion & Shock Waves

Wanamaker J (1951) Rotary percussion drilling in west Texas. World Oil 133:182

Whiteley MC, England WP (1985) Air drilling operations improved by percussion bit/hammer tool tandem. SPE/IADC Drilling Conference. Society of Petroleum Engineers

Wu A, Hareland G, Lei L (2014) Computer simulation and analysis of rock breaking process by rock bit cutters. 48th US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Yang Y, Liao H, Xu Y, Niu J, Yang L (2019) Theoretical investigation of the energy transfer efficiency under percussive drilling loads. Arab J Geosci 12:175

Zhao F-J, Li X-B, Feng T et al (2005) Theoretical analysis and experiments of rock fragmentation under coupling dynamic and static loads. Yanshilixue Yu Gongcheng Xuebao/Chin J Rock Mech Eng 24:1315–1320

Acknowledgements

Thanks to all co-authors for their help in preparation for this paper.

Funding

This research was supported by the Foundation of State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development (Grant No. 18-ZC0607-0023); Shandong Provincial Natural Science Foundation, China (Grant No. ZR2019MEE120); and National Natural Science Foundation of China (Grant No. 51274235).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Santanu Banerjee

Rights and permissions

About this article

Cite this article

Yang, Y., Liao, H., Niu, J. et al. Three-dimensional simulation of rock breaking efficiency under various impact drilling loads. Arab J Geosci 13, 444 (2020). https://doi.org/10.1007/s12517-020-05471-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-05471-y