Abstract

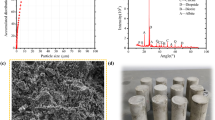

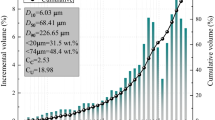

Failure evolution of cemented paste backfill (CPB) is crucial to the stope stability in the mining industry. While many effects have been done on the strength requirement and macroscopic deformation behaviors of CPB, the mesoscopic failure mechanism is not yet well understood. In this work, a uniaxial compressive test on the CPB sample from Lilou iron mining was conducted under topographic monitoring using a 450-kV industrial X-ray computed tomography (CT). A specific self-developed loading device was used to match the CT machine to realize the real-time CT scanning. A series of 2D CT images were obtained by carrying out CT scanning at seven stages throughout sample deformation and from different positions in the sample. Clear CT images, CT value analysis, and void identification and extraction reveal that the sample experiences compression, damage, crack initiation, crack propagation, crack coalescence, and collapse stages. Besides, a damage constitutive equation is proposed first using the CT data, which can be used to predict the stress strain response of CPB. What is more, volumetric dilatancy characteristics caused by the damage and cracking behavior are investigated from the stress strain curve and the CT images, the result reveals the influence of localization deformation on the failure evolution of CPB. Through a series of meso-structural changes analysis, the meso-mechanisms of failure evolution in CPB have been first documented.

Similar content being viewed by others

References

Anay R, Soltangharaei V, Assi L, DeVol T, Ziehl P (2018) Identification of damage mechanisms in cement paste based on acoustic emission. Constr Build Mater 164:286–296

Assi L, Anay R, Leaphart D, Soltangharaei V, Ziehl P (2018) Understanding early geopolymerization process of Fly ash–based geopolymer paste using pattern recognition. J Mater Civ Eng 30(6):04018092

Belem T, Benzaazoua M (2008a) Design and application of underground mine paste backfill technology. Geotech Geol Eng 26(2):147–174

Belem T, Benzaazoua M (2008b) Predictive models for pre-feasibility cemented paste backfill mix design, in: the 3rd International Conference on Post-mining, 08; February; Nancy, France, 2008

Cayouette J (2003) Optimization of the paste backfill plant at Louvicourt mine. CIM Bull 96(1075):51–57

Chen QS, Zhang QL, Fourie A, Chen X, Qi CC (2017) Experimental investigation on the strength characteristics of cement paste backfill in a similar stope model and its mechanism. Constr Build Mater 154:34–43

Cnudde V, Boone MN (2013) High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth Sci Rev 123:1–17

Du XJ, Feng GR, Guo YX, Qi TY, Zhang YJ, Guo J (2018) Failure analyses of unconfined CCWBM body in uniaxial compression based on central pressure variation. Waste Manag Res 36(2):159–168

Duchesne MJ, Moore F, Long BF, Labrie J (2009) A rapid method for converting medical computed tomography scanner topogram attenuation scale to Hounsfield unit scale and to obtain relative density values. Eng Geol 103(3–4):100–105

Fahey M, Helinski M, Fourie A (2011) Development of specimen curing procedures that account for the influence of effective stress during curing on the strength of cemented mine backfill. Geotech Geol Eng 29(5):709–723

Fall M, Pokharel M (2013) Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem Concr Compos 32(10):819–828

Fall M, Benzaazoua M, Ouellet S (2005) Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner Eng 18(1):41–44

Fall M, Belem T, Samb S, Benzaazoua M (2007) Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J Mater Sci 42(11):3914–3922

Galaa AM, Thompson BD, Grabinsky MW, Bawden WF (2011) Characterizing stiffness development in hydrating mine backfill using ultrasonic wave measurements. Can Geotech J 48(8):1174–1187

Galaa A, Grabinsky A, Bawden W (2012) Characterizing stiffness development in early age cemented paste backfills with sand in a non-destructive triaxial test. In Canadian Geotechnical Conference, GeoManitoba

GB/T 175-2007 (2007) Common Portland cement

Grayling KM, Young SD, Roberts CJ, de Heer MI, Shirley IM, Sturrock CJ, Mooney SJ (2018) The application of X-ray micro computed tomography imaging for tracing particle movement in soil. Geoderma 321:8–14

Hirono T, Takahashi M, Nakashima S (2003) In situ visualization of fluid flow image within deformed rock by X-ray CT. Eng Geol 70(1):37–46

Hounsfield GN (1972) A method of and apparatus for examination of a body by radiation such as X-or gamma-radiation. British Patent No 1,283,915

Huang JZ, Wang JW (2009) China Association of Resource Comprehensive Utilization. In: Development report on bulk industrial solid waste comprehensive utilization. Light Industry Press, Beijing, China

Huang Y, Zhang J, Zhang Q, Nie S (2011) Backfilling technology of substituting waste and fly ash for coal underground in China coal mining area. Environ Eng Manag J 10(6):112–121

Jiang H, Fall M (2017) Yield stress and strength of saline cemented tailings in sub-zero environments: Portland cement paste backfill. Int J Miner Process 160:68–75

Ke X, Hou H, Zhou M, Wang Y, Zhou X (2015) Effect of particle gradation on properties of fresh and hardened cemented paste backfill. Constr Build Mater 96:378–382

Klein K, Simon D (2006) Effect of specimen composition on the strength development in cemented paste backfill. Can Geotech J 43(3):310–324

Koohestani B, Koubaa A, Belem T, Bussière B, Bouzahzah H (2016) Experimental investigation of mechanical and microstructural properties of cemented paste backfill containing maple-wood filler. Constr Build Mater 121:222–228

Koohestani B, Bussière B, Belem T, Koubaa A (2017) Influence of polymer powder on properties of cemented paste backfill. Int J Miner Process 167:1–8

Kumari WGP, Ranjith PG, Perera MSA, Li X, Li LH, Chen BK, De Silva VRS (2018) Hydraulic fracturing under high temperature and pressure conditions with micro CT applications: geothermal energy from hot dry rocks. Fuel 230:138–154

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge

Li W, Fall M (2016) Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr Build Mater 106:296–304

Liu L, Fang ZY, Wu YP, Lai XP, Wang P, Song KI (2018a) Experimental investigation of solid-liquid two-phase flow in cemented rock-tailings backfill using electrical resistance tomography. Constr Build Mater 175:267–276

Liu L, Fang Z, Qi C, Zhang B, Guo L, Song KI (2018b) Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol 343:454–464

Passariello B, Giuliano V, Quaresima S, Barbaro M, Caroli S, Forte G, Carelli G, Iavicoli I (2002) Evaluation of the environmental contamination at an abandoned mining site. Microchem J 73:245–250

Rong H, Zhou M, Hou H (2017) Pore structure evolution and its effect on strength development of sulfate-containing cemented paste backfill. Minerals 7(1):8–18

Singh UK, Digby PJ (1989) A continuum damage model for simulation of the progressive failure of brittle rocks. Int J Solids Struct 25(6):647–663

Sivakugan N, Rankine RM, Rankine KJ, Rankin KS (2006) Geotechnical considerations in mine backfilling in Australia. J Clean Prod 14:1168–1175

Wang Y, Li X, Wu YF, Lin C, Zhang B (2015) Experimental study on meso-damage cracking characteristics of RSA by CT test. Environ Earth Sci 73(9):5545–5558

Wang Y, Li CH, Hao J, Zhou RQ (2018a) X-ray micro-tomography for investigation of meso-structural changes and crack evolution in Longmaxi formation shale during compressive deformation. J Pet Sci Eng 164:278–288

Wang Y, Li C, Hou Z, Yi X, Wei X (2018b) In vivo X-ray computed tomography investigations of crack damage evolution of cemented waste rock backfills (CWRB) under uniaxial deformation. Minerals 8(11):539

Xu S, Suorineni FT, Li K, Li Y (2017) Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. Int J Min Reclam Environ 31(8):544–557

Yilmaz KE, Ercikdi B (2004) Evaluation of paste backfill mixture consisting of sulphide-rich mill tailings and varying cement content. Cem Concr Res 34:1817–1822

Yılmaz T, Ercikdi B (2016) Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test. Nondestruct Test Eval 31(3):247–266

Yilmaz E, Benzaazoua M, Belem T, Bussière B (2009) Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner Eng 22(9–10):772–785

Yilmaz E, Belem T, Bussière B, Benzaazoua M (2011) Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cement Concr Compos 33(6):702–715

Yin SH, Wu AX, Hu KJ, Wang Y, Zhang YK (2012) The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner Eng 35:61–66

Zhang S, Xue X, Liu X, Duan P, Yang H, Jiang T, Wang D, Liu R (2006) Current situation and comprehensive utilization of iron ore tailing resources. J Min Sci 42:403–408

Zhou XP, Zhang YX, Ha QL (2008) Real-time computerized tomography (CT) experiments on limestone damage evolution during unloading. Theor Appl Fract Mech 50(1):49–56

Acknowledgements

The authors would like to thank the editors and the anonymous reviewers for their helpful and constructive comments.

Funding

This study was supported by the National Key Technologies Research & Development Program (2018YFC0808402, 2018YFC0604601), the Fundamental Research Funds for the Central Universities (2302017FRF-TP-17-027A1), and National Natural Science Foundation of China (Grants Nos. 41502294).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial handling: F. Dai

Rights and permissions

About this article

Cite this article

Wang, Y., Liu, D. & Hu, Y. Monitoring of internal failure evolution in cemented paste backfill under uniaxial deformation using in-situ X-ray computed tomography. Arab J Geosci 12, 138 (2019). https://doi.org/10.1007/s12517-019-4285-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-019-4285-4