Abstract

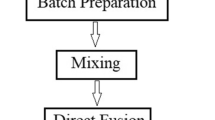

The aim of this study is to use produce borosilicate cullet by using rice husk ash (RHA). For this purpose, rice husk ash was first characterized by X-ray diffraction (XRD), SEM, and chemical analyses. Borosilicate cullet is generally produced by direct fusion of precisely measured portions of boron oxide source and quartz (SiO2). In this study, rice husk ash was used as a source of SiO2. Different batches were prepared and fused to produce borosilicates varying in ratio B2O3·nSiO2. Produced samples were evaluated by X-ray diffraction (XRD) and scanning electron microscopy (SEM). The results indicate that borosilicate cullets can be produced by using rice husk ash. The best result was obtained with the sample that contained 42.05% rice husk ash content melted at 1100 °C.

Similar content being viewed by others

References

Alharbi AF, Jolley K, Smith R, Archer AJ, Christie JK (2017) A new potential for radiation studies of borosilicate glass. Nucl Instrum Methods Phys Res Sect B: Beam Interact Mater Atoms 393:73–76. https://doi.org/10.1016/j.nimb.2016.12.007

Andreola F, Martín MI, Ferrari AM, Lancellotti I, Bondioli F, Rincón JM, Romero M, Barbieri L (2013) Technological properties of glass-ceramic tiles obtained using rice husk ash as silica precursor. Ceram Int 39:5427–5435. https://doi.org/10.1016/j.ceramint.2012.12.050

Görhan G, Şimşek O (2013) Porous clay bricks manufactured with rice husks. Constr Build Mater 40:390–396. https://doi.org/10.1016/j.conbuildmat.2012.09.110

Kılınçarslan S (2015) Investigation of heavy concretes produced with heavy artificial aggregates. Acta Phys Pol A 128:B-469–B-470. https://doi.org/10.12693/APhysPolA.128.B-469

Konijnendijk WL (1975) The structure of borosilicate glasses. Dissertation, Technische Hogeschool Eindhoven

Martín MI, Andreola F, Barbieri L, Bondioli F, Lancellotti I, Rincón JM, Romero M (2013) Crystallisation and microstructure of nepheline–forsterite glass-ceramics. Ceram Int 39:2955–2966. https://doi.org/10.1016/j.ceramint.2012.09.072

Özavcı S, Çetin B (2016) Determination of radiation attenuation coefficients in concretes containing different wastes. Acta Phys Pol A 130:316–317. https://doi.org/10.12693/APhysPolA.130.316

Rockett TJ, Foster WR (1965) Phase relations in the system boron oxide–silica. J Am Ceram Soc 48(2):75–80. https://doi.org/10.1111/j.1151-2916.1965.tb11803.x

Siqueira EJ, Yoshida IVP, Pardini LC, Schiavon MA (2009) Preparation and characterization of ceramic composites derived from rice husk ash and polysiloxane. Ceram Int 35:213–220. https://doi.org/10.1016/j.ceramint.2007.10.013

Sobrosa FZ, Stochero NP, Marangon E, Tier MD (2017) Development of refractory ceramics from residual silica derived from rice husk ash. Ceram Int 43:7142–7146. https://doi.org/10.1016/j.ceramint.2017.02.147

Tozlu A, Abusoglu A, Özahi E (2017) Thermoeconomic analysis and assessment of Gaziantep municipal solid waste power plant. Acta Phys Pol A 132:513–517. https://doi.org/10.12693/APhysPolA.132.513

Tuscharoen S, Ruengsri S, Kaewkhao J (2013) Development of barium borosilicate glass using rice husk ash: effect of BaO. Adv Mater Res 170:201–204. https://doi.org/10.4028/www.scientific.net/AMR.770.201

Yıldız F, Parlar AG, Parlar Z, Bakkal M (2017) Properties of sound panels made from recycled footwear treads. Acta Phys Pol A 132:936–940. https://doi.org/10.12693/APhysPolA.132.93

Yılmaz F, Kamiloglu HA, Sadoglu E (2015) Soil stabilization with using waste materials against freezing thawing effect. Acta Phys Pol A 128:B-392–B-394. https://doi.org/10.12693/APhysPolA.128.B-392

Acknowledgments

This work was supported by the Dokuz Eylül University Scientific Research Project within the project number 2018.KB.FEN.022.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Geo-Resources-Earth-Environmental Sciences

Rights and permissions

About this article

Cite this article

Özkan, İ., Dokumacı, E. Production of borosilicate cullet by using rice husk ash. Arab J Geosci 12, 42 (2019). https://doi.org/10.1007/s12517-018-4198-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-4198-7