Abstract

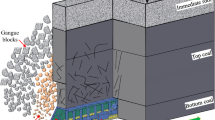

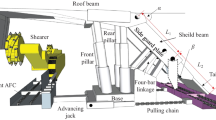

A good understanding of the caving mechanisms of loose top-coal is significant for longwall top-coal caving (LTCC) mining. In this paper, the equations of the particle motion, top-coal boundary, and drawing body were derived based on the stochastic medium theory. Then, the particles moving boundary and the shape of the top-coal loss were discussed, and the dynamic evolvement of the top-coal boundary and drawing body was analyzed. A theoretical model for calculating the top-coal recovery ratio was established, and the relationship between the top-coal recovery ratio and rock mixed ratio was studied and then the criterion for terminating the drawing cycle was proposed. Finally, model experiments were conducted to verify the theoretical analysis. It is concluded that the starting top-coal boundary keeps moving to the lower left with increasing drawing volume. The top-coal loss is zonal distribution and tilts toward the goaf and is composed of the top-coal surrounded by the floor, the starting top-coal boundary and the ending top-coal boundary between the drawing window and the lowest moving point in the starting top-coal boundary. The drawing body tilts toward the goaf and its deflection angle decreases with increasing drawing volume. The top-coal recovery ratio increases non-linearly with increasing rock mixed ratio, and the rock mixed ratio of 10–15% can be used as the criterion for terminating the drawing cycle. This work is the first attempt at demonstrating the caving mechanisms of the loose top-coal using the stochastic medium theory in LTCC mining.

Similar content being viewed by others

References

Alehossein H, Poulsen BA (2010) Stress analysis of longwall top coal caving. Int J Rock Mech Min Sci 47:30–41

Bai YR, Bai SW, Jin ZM, Song XM (2001) Testing study of similar material for layer-divided top coal caving in specially thick coal seam. Chin J Rock Mech Eng (China) 20(3):365–369

Bai YS, Tu SH, Wang C (2014) Numerical simulation on top-coal arching mechanism. J Min Saf Eng (China) 31(2):208–213

Basarir H, Oge IF, Aydin O (2015) Prediction of the stresses around main and tail gates during top coal caving by 3D numerical analysis. Int J Rock Mech Min Sci 76:88–97

Chen ZH, Xie HP, Wang JC (2002) Numerical simulation on three dimensional deformation and failure of top coal caving. Chin J Rock Mech Eng (China) 21(3):309–313

Chen QF, Chen ZH, Li H, Zeng D (2014) Experimental study on fully mechanized top coal caving law in Pingshuo mining area. Coal Eng (China) 46(1):90–93

David J (1968) Computer simulation of the movement of ore and waste in an underground mining pillar. Can Min Metall 67(2):854–859

Huang BX, Liu CY, Cheng QY (2007) Relation between top-coal drawing ratio and refuse content for fully mechanized top coal carving. J China Coal Soc (China) 32(8):789–793

Huang BX, Liu CY, Niu HW et al (2008) Research on coal-gangue flow field character resulted from great cutting height fully mechanized top coal caving. J Min Saf Eng (China) 25(4):415–419

Jiang JQ, Qu H, Tan YL (2004) Numerical simulation by distinct element code on drawing law and interval of fully-mechanized coal mining with caving method. Chin J Rock Mech Eng (China) 23(18):3070–3075

Litwiniszyn J (1956) Application of the equation of stochastic processes to mechanics of loose bodies. Arch Mech Stos 8(4):393–411

Liu BC, Zhang JS (1995) Stochastic method for ground subsidence due to near surface excavation. Chin J Rock Mech Eng (China) 14(4):289–295

Ren FY (1994) Application of ore caving-drawing based stochastic medium theory. Beijing

Shao XP, Zhang HX, Shi PW (2009) Selection of reasonable section heights during top-coal caving to steep seams. J China Univ Min Technol 38(4):544–548

Simsir F, Ozfirat MK (2008) Determination of the most effective longwall equipment combination in longwall top coal caving (LTCC) method by simulation modelling. Int J Rock Mech Min Sci 45:1015–1023

Wang SH, Ren FY, Wei YJ et al (2003) Experimental physical simulation of mineral moving. J Northeastern Univ (Nat Sci) 24(7):699–702

Wang JC, Wei LK, Zhang JW et al (2013) 3-D numerical simulation on the top-coal movement law under caving mining technique. J China Coal Soc (China) 38(11):1905–1911

Wang JC, Yang SL, Li Y, Wei L, Liu H (2014) Caving mechanisms of loose top-coal in longwall top-coal caving mining method. Int J Rock Mech Min Sci 71:160–170

Wang JC, Zhang JW, Yang SH et al (2015) 3-D movement law of top-coal in near horizontal coal seam with multi-gangue under caving mining technique. J China Coal Soc (China) 40(5):979–987

Wang JC, Zhang JW, Li ZL (2016) A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int J Rock Mech Min Sci 88:273–285

Wu J (1991) Theory and practice of sub-level caving method in China. J China Coal Soc (China) 16:1–11

Wu J, Zhang Y (1998) Study on the basic theory of longwall top-coal caving system. J China Univ Min Technol 27(4):332–335

Yang SL, Zhang JW, Chen Y, Song Z (2016) Effect of upward angle on the drawing mechanism in longwall top-coal caving mining. Int J Rock Mech Min Sci 85:92–101

Yasitli NE, Unver B (2005) 3D numerical modeling of longwall mining with top-coal caving. Int J Rock Mech Min Sci 42:219–235

Yu HY, Jia EL, Mu RC (1995) Basic theory of top-coal caving mining. Beijing

Zhang KZ, Jiang JQ, Wu SL (2003) Experimental study on reasonable coal drawing interval. J China Coal Soc (China) 28(3):246–250

Zhang Y, Si YL, Shi L (2011) Numerical simulation of the effect of particle size on coal caving ratio. J Min Saf Eng (China) 28(2):247–251

Zhang YD, Zhang FT, Ji M et al (2012) Research on the reasonable coal caving technological parameters of extra-thick coal seam. J Min Saf Eng (China) 29(6):808–814

Funding

The study was financially supported by the National Natural Science Foundation of China (No. U1361209).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Top-coal boundary—the boundary between the waste rock and top-coal. The starting top-coal boundary is the top-coal boundary before the current drawing cycle begins, and the ending top-coal boundary is the top-coal boundary after the current drawing cycle being terminated.

Drawn top-coal—the top-coal flowing out from the drawing window during the drawing process.

Drawing body—the original shape of the drawn top-coal and rock.

Drawing volume—equaling the area of the drawing body in the theoretical analysis and the quality of the drawn top-coal and rock in experiments.

Drawing interval—when the current drawing cycle is terminated, the shield support will be moving along the mining direction and the next drawing cycle will begin, the corresponding moving distance is the drawing interval.

Rights and permissions

About this article

Cite this article

Zhu, D., Chen, Z., Du, W. et al. Caving mechanisms of loose top-coal in longwall top-coal caving mining based on stochastic medium theory. Arab J Geosci 11, 621 (2018). https://doi.org/10.1007/s12517-018-3987-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3987-3