Abstract

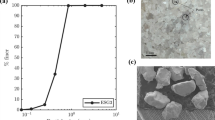

The air leakage in goaf can easily lead to disasters such as spontaneous combustion process of residual coal and gas accumulation, threatening production safety in underground coal mines. In order to study and master air leakage flow field distribution in goaf, the particle flow numerical simulation software PFC3D is used for the simulation of the collapse of overlying rock strata with the actual situation of the 3308 working face of Liangbaosi Coal Mine in China taken as an example. The quantitative porosity data of goaf are extracted and imported into FLUENT to simulate the air leakage flow field in goaf. The results show that (1) the porosity in the central part and near the working face of goaf is relatively large. With the increase of the length of goaf, the porosity decreases, and with the increase of the height of goaf, the porosity in the two cross headings is first larger than that in the central part and then smaller than that in the central part. (2) The data of air flow along the dip direction of working face obtained through the CFD numerical simulation is consistent with the actual measurement results basically, which validate the simulation. (3) The main air leakage occurs in the range of 0–10 m along the dip direction of working face. In the case of relatively large air supply rate, the residual coal spontaneous combustion area in goaf is far from the working face and the spontaneous combustion area becomes relatively large, resulting in increased risk.

Similar content being viewed by others

References

Byon C, Kim SJ (2013) The effect of the particle size distribution and packing structure on the permeability of sintered porous wicks. Int J Heat Mass Transf 61:499–504

Cheng WM, Yu HM, Zhou G, Nie W (2016) The diffusion and pollution mechanisms of airborne dusts in fully-mechanized excavation face at mesoscopic scale based on CFD-DEM. Process Saf Environ Prot 104:240–253

Cheng WM, Hu XM, Xie J, Zhao YY (2017) An intelligent gel designed to control the spontaneous combustion of coal: fire prevention and extinguishing properties. Fuel 210:826–835

Cheng WM, Liu Z, Yang H, Wang WY (2018) Non-linear seepage characteristics and influential factors of water injection in gassy seams. Exp Thermal Fluid Sci 91:41–53

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29:47–65

Deng QW, Liu XH, Lu C, Lin QZ, Yu MG (2013) Numerical simulation of spontaneous oxidation zone distribution in goaf under gas stereo drainage. Procedia Eng 52:72–78

Ding HC, Jiang ZG, Zhu QM (2012) Optimized parameters and forecast analysis of high-position hole for goaf gas drainage. Procedia Eng 45:305–310

Ding XB, Zhang LY, Zhu HH, Zhang Q (2014) Effect of model scale and particle size distribution on PFC3D simulation results. Rock Mech Rock Eng 47(6):2139–2156

Gao FQ, Stead D, Coggan J (2014) Evaluation of coal longwall caving characteristics using an innovative UDEC trigon approach. Comput Geotech 55:448–460

Itasca Consulting Group Inc (2010) PFC2D-particle flow code in two dimensions. Ver. 4.0 user’s manual. ICG Minneapolis

Kurnia JC, Sasmito AP, Mujumdar AS (2014) CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl Math Model 38(14):3467–3484

Luo HS, Quintard M, Debenest G, Laouafa F (2012) Properties of a diffuse interface model based on a porous medium theory for solid–liquid dissolution problems. Comput Geosci 16(4):913–932

MacDonald MJ, Chu CF, Guilloit PP, Ng KM (1991) A generalized Blake–Kozeny equation for multisized spherical particles. AICHE J 37(10):1583–1588

Menon KG, Patnaikuni VS (2017) CFD simulation of fuel reactor for chemical looping combustion of Indian coal. Fuel 203:90–101

Ni GH, Cheng WM, Lin BQ, Zhai C (2016) Experimental study on removing water blocking effect (WBE) from two aspects of the pore negative pressure and surfactants. J Nat Gas Sci Eng 31:596–602

Pan RK, Cheng YP, Yu MG, Lu C, Yang K (2013) New technological partition for “three zones” spontaneous coal combustion in goaf. Int J Min Sci Technol 23(4):489–493

Ren TX (2009) CFD modelling of longwall goaf gas flow to improve gas capture and prevent goaf self-heating. J Coal Geol 3:225–228

Schatzel SJ, Karacan CÖ, Dougherty H, Goodman VR (2012) An analysis of reservoir conditions and responses in longwall panel overburden during mining and its effect on gob gas well performance. Eng Geol 127:65–74

Szlazak J (2001) The determination of a co-efficient of longwall gob permeability. Archives of Mining Sciences 46(4):451–468

Tan B, Shen J, Zuo DF, Guo XP (2011) Numerical analysis of oxidation zone variation in goaf. Procedia Eng 26:659–664

Tang MY, Jiang BY, Zhang RQ, Yin ZQ, Dai JL (2016) Numerical analysis on the influence of gas extraction on air leakage in the gob. J Nat Gas Sci Eng 33:278–286

Taraba B, Michalec Z (2011) Effect of longwall face advance rate on spontaneous heating process in the gob area—CFD modelling. Fuel 90(8):2790–2797

Wang T, Zhou WB, Chen JH, Xiao X, Li Y, Zhao XY (2014) Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int J Coal Geol 121:1–13

Wang G, Wu MM, Wang R, Xu H, Song X (2017) Height of the mining-induced fractured zone above a coal face. Eng Geol 216:140–152

Wolf KH, Bruining H (2007) Modelling the interaction between underground coal fires and their roof rocks. Fuel 86(17–18):2761–2777

Wu JJ, Liu XC (2011) Risk assessment of underground coal fire development at regional scale. Int J Coal Geol 86(1):87–94

Yang YL, Li ZH, Tang YB, Liu Z, Ji HJ (2014) Fine coal covering for preventing spontaneous combustion of coal pile. Nat Hazards 74(2):603–622

Yu ZY, Yang SQ, Qin Y, Hu XC, Cheng JW (2015) Experimental study on the goaf flow field of the “U+I” type ventilation system for a comprehensive mechanized mining face. Int J Min Sci Technol 25(6):1003–1010

Yuan LM, Smith AC (2008) Numerical study on effects of coal properties on spontaneous heating in longwall gob areas. Fuel 87(15–16):3409–3419

Zhang Z, Ji SF (2016) Numerical simulation of particle/monolithic two-stage catalyst bed reactor with beds-interspace distributed dioxygen feeding for oxidative coupling of methane. Comput Chem Eng 90:247–259

Zhao ZL, Wen ZJ (2017) Design and application of a mining-induced stress testing system. Geotech Geol Eng 5:1–10

Zhu HQ, Liu XK (2012) Theoretical investigation on the relationship between tail roadway methane drainage and distribution of easily spontaneous combustible region in gob. Saf Sci 50(4):618–623

Funding

The authors would like to acknowledge the support of the National Key Research and Development Program of China (Project No. 2017YFC0805201), National Natural Science Foundation of China (Project No. 51674158), the Taishan Scholar Talent Team Support Plan for Advantaged & Unique Discipline Areas, the Source Innovation Program (Applied Research Special-Youth Special) of Qingdao (Project No. 17-1-1-38-jch), and the Open Fund of Hebei State Key Laboratory of Mine Disaster Prevention(Project No. KJZH2017K10), as well as Shandong University of Science and Technology Research Fund (Project No. 2015JQJH105).

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• The particle flow numerical simulation software PFC3D is used for the simulation of the collapse of overlying rock strata, and the porosity distribution in goaf is obtained.

• The porosity data of goaf obtained by PFC3D are imported into FLUENT in the form of UDF, and then the flow field distribution in goaf is analyzed.

• The trend of air flow distribution along the dip direction of working face obtained through CFD is consistent with the actual measurement results basically, which validates the simulation.

Electronic supplementary material

ESM 1

(C 18 kb)

Rights and permissions

About this article

Cite this article

Wang, G., Xu, H., Wu, M. et al. Porosity model and air leakage flow field simulation of goaf based on DEM-CFD. Arab J Geosci 11, 148 (2018). https://doi.org/10.1007/s12517-018-3499-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3499-1