Abstract

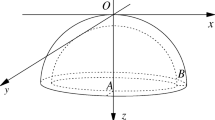

In order to master the tendency mining-fracture-evolution characteristics of overlying strata and coal seams above working face with large inclination angle and mining depth in mining process, the 1221 working face in Zhao mine is selected as the engineering background and a mathematical model is established. The displacement variation, stress and strain of overlying strata and coal seams are simulated by using ANSYS software. In the mining process, the movement characteristics, displacement variation laws and fracture evolution characteristics of overlying strata and coal seams above working face with large inclination angle and mining depth along inclination direction are discussed. Simulation results show that with the advance of working face, the fracture development of overlying strata and coal seams is larger and larger; the area of gob is gradually expanding and the transverse stress of overlying strata and coal seams is also expanding. Stress contour of overlying strata and coal seams at both ends of gob becomes denser and denser; the activity of the overlying strata and coal seams near the up-roadway side of the gob is violent. The pressure relief zone is formed in the upper part of the strata and the roof above the gob. Large inclination angle of coal seam results in larger supporting pressure in the underside of the gob and smaller supporting pressure in the upper side of the gob. Along the inclination direction of the working face, the pressure relief zone is mainly concentrated in the outlet roadway of the working face; the fracture development and strata separation are obvious, which offer good passage for gas flow and migration.

Similar content being viewed by others

References

Huang B, Liu C, Xu J (2010) Research on through degree of overlying strata fracture fissure induced by mining. Journal of China University of Mining & Technology 39(1):45–49 N0:1000-1964(2010)01-0045-05

Ke Y, Xiang H, Litong D, Wenjun L, Li S, Haisong Y (2015) Experimental investigation into stress-relief characteristics with upward large height and upward mining under hard thick roof. International Journal of Coal Science and Technology 2(1):91–96. doi:10.1007/s40789-015-0066-1

Li S (2014) Dynamic evolution of mining fissure elliptic parabolic zone and extraction coal and gas. J China Coal Soc 39(8):1455–14562. http://www.cnki.com.cn/Article/CJFDTotal-MTXB201408012.htm. Accessed 28 Dec 2016

Liao M, Wang B (2012) Numerical simulation study on crack evolution in overburden strata of top goaf. Science Technology and Engineering 12(25):6286–6289 No: 1671-1815( 2012) 25-6286-04

Liu Z, Yuan L, Dai G, Shi B, Lu P, Tu M (2004) Study on coal seam roof gas drainage from the strike of annular fracture areas by the long drill method. Engineering Science 5(5):32–38 No: 1009-1742 (2004) 05-0032-07

Liu S, Lin B, Gao J, Hao Z, Li Q, Meng J (2011) Similar simulation of fracture deformation in overlying coal and rock in far-distance-lower-protective-layer mining. Journal of Mining and Safety Engineering. 28(1):51–55 No: 1673-3363(2011)01-0051-05

Liu C, Xue J, Yu G, Cheng X (2016) Fractal characterization for the mining crack evolution process of overlying strata based on micro seismic monitoring technology. Int J Min Sci Technol 26(2):215–219. doi:10.1016/j.ijmst.2015.12.016

Tu M, Miao X, Huang N (2006) Deformation rule of protected coal seam exploited by using the long-distance-lower protective seam method. Journal of Mining and Safety Engineering. 23(3):253–257 No: 1673-3363(2006)03-0253-05

Wei X, Gao M, Lv Y, Shi X, Gao H, Zhou H (2012) Evolution of a mining induced fracture network in the overburden strata of an inclined coal seam. Int J Min Sci Technol 22(6):779–783. doi:10.1016/j.ijmst.2012.11.004

Xie HP, Yu GM, Yang L, Zhang YZ (1999) Research on the fractal effects of crack network in overburden rock stratum. Chin J Rock Mech Eng 18(2):147–151

Yang Z, Tong B, Huang C, Wang G (2012) Study of caving and fracturing over a long wall panel beneath a goaf mined by room and pillar. Journal of Mining and Safety Engineering 29(2):157–161 No: 1673-3363-(2012)02-0157-05

Zhou H, Zhang T, Xue D, Xue J (2012) Evolution of mining-crack network in overburden strata of long wall face. Journal of the China Coal Society 36(12):57–63 No: 0253-9993(2011)12-1957-06

Acknowledgements

This work is supported by the National Natural Science Foundation Project of China (51004048, 51374003, 51434006) and Hunan Provincial Natural Science Foundation Project (2016JJ6038, E51523). Those supports are greatly acknowledged with thanks.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, Q., Wang, Wj., Wang, G. et al. Numerical simulation on tendency mining fracture evolution characteristics of overlying strata and coal seams above working face with large inclination angle and mining depth. Arab J Geosci 10, 82 (2017). https://doi.org/10.1007/s12517-017-2856-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-017-2856-9