Abstract

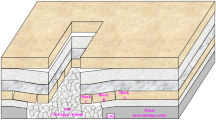

Gob-side entry (GSE) is defined as caving that is developed along the gob with a yield pillar. Compared to other entry layouts, GSE has many advantages, such as the advantageous stress environment, high recovery rate, and prevention of coal bumps. Recently, many Chinese coal mines have reached deep mining depths. As a result of the high stress in deep mining conditions, severe bulk and dilatant deformation has occurred in deep GSE (DGSE). The direct problems in this situation, such as interruptions to production, increasing rehabilitation cost, and high labor consumption, affect the safety and mining efficiency of deep coal seams. In this paper, based on analysis of the deformation characteristics of a typical DGSE, numerical modeling was used to study the causes and mechanism of DGSE failure. In addition, a series of strategies are proposed for DGSE deformation control. The case study presented indicates that the proposed control strategies can prevent severe deformation of the DGSE. Thus, the results of this research can be used as a reference for DGSE control in other deep mining settings.

Similar content being viewed by others

References

Badr S, Schissler A, Salamon M, Ozbay U (2002) Numerical modeling of yielding chain pillars in longwall mines. In: NARMS-TAC, Hammahetal R (eds) Mining and tunnelling innovation and opportunity. University of Toronto, Toronto, pp 99–106

Bai JB (2006) Surrounding rock control of gob-side entry driving. China University of Mining and Technology Press, Xuzhou (in Chinese)

Bai JB, Wang WJ, Hou CJ, Huang HF (2000) Control mechanism and support technique about gateway driven along goaf in fully mechanized top coal caving face. J China Coal Soc 25:478–481 (in Chinese)

Campoli AA, Barton TM, Van Dyke FC, Gauna M (1990) Mitigation destructive longwall bumps through conventional gate entry design. US Bureau of Mines, RI 9325, pp 38

Carr F, Martin E, Gardner BH (1985) How to eliminate roof and floor failures with yield pillar. Coal Min Part II:44–49

Cheng YM, Wang JA, Xie GX, Wei WB (2010) Three-dimensional analysis of coal barrier pillars in tailgate area adjacent to the fully mechanized top caving mining face. Int J Rock Mech Min Sci 47:1372–1383

CNDRC (2012) The 12th five-year plan for the development of coal industry. The Chinese National Development and Reform Commission, Beijing (in Chinese)

Colwell M, Frith R (1999) Calibration of the analysis of longwall pillar stability (ALPS) chain pillar design methodology for Australian conditions. In: Proceeding of 18th international conference on ground control in mining, West Virginia University, Morgantown, WV, pp 282–289

Du JP, Meng XR (2009) Mining science. China University of Mining and Technology Press, Xuzhou (in Chinese)

Esterhuizen G (2000) Jointing effects on pillar strength. In: Proceeding of 19th international conference on ground control in mining, West Virginia University, Morgantown, WV, pp 286–290

Itasca Consulting Group (2007) FLAC3D Instruction manual, Minnesota

Kang HP, Lin J (2007) High pretensioned stress and intensive bolting system and its application to deep roadways. J China Coal Soc 32:1233–1238 (in Chinese)

Kang HP, Lin J, Wu YZ (2009) Development of high pretensioned and intensive supporting system and its application in coal mine roadways. In: Proceedings of the 6th international conference on mining science and technology. China University of Mining and Technology, Xuzhou, China, pp 480–485

Li L, Bai JB, Wang XY (2012a) Rational position and control technique of roadway driving along next goaf in fully mechanized top coal caving face. J China Coal Soc 37:1564–1569 (in Chinese)

Li WF, Bai JB, Syd P, Wang XY, Xu Y (2014) Numerical modeling for yield pillar design: a case study. Rock Mech Rock Eng. doi:10.1007/s00603-013-0539-8

Li XH, Liang S, Yao QL, Qu QD (2012b) Control principle and its application of rock burst in roadway driving along goaf with outburst-proneness surrounding rocks. J Min Saf Eng 29:751–756 (in Chinese)

Lu J, Anil R, Khaled M, Syd P (2008) Effects of rock/coal interface property on coal pillar strength. In: Proceeding of 27th international conference on ground control in mining, West Virginia University, Morgantown, WV, pp 262–267

Ma ZT, Gao DC, Li RR (2013) Determination and failure mechanism of coal pillar of driving roadway along goaf in deep mining. In: Proceedings of the 3rd international workshop on mine hazards prevention and control. CSIRO Earth Sci & Resource Engn, Brisbane, Australia, pp 19–21

Mark C (1990) Pillar design methods for longwall mining. Pittsburgh, Pennsylvania

Moodie A, Anderson J (2011) Geotechnical considerations for longwall top coal caving at Austar coal mine. In: Underground Coal Operators’ Conference, Wollongong, NSW, February 10–11, pp 29–39

Perry KA, Unrug KF, Harris KW, Raffaldi MJ (2012) Influence of roof/floor interface on coal pillar performance. In: Proceeding of 32th international conference on ground control in mining, West Virginia University, Morgantown, WV, pp 1–7

Qian MG, Shi PW (2003) Mining pressure and strata control. China University of Mining and Technology Press, Xuzhou (in Chinese)

Salamon MDG (1990) Mechanism of caving in longwall coal mining. Rock mechanics contribution and challenges: proceedings of the 31st US symposium of rock mechanics, Golden, Colorado, pp 161–168

Shabanimashcool M, Li CC (2012) Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int J Rock Mech Min Sci 51:24–34

Vakili A (2009) Cavability assessment in longwall top coal caving technology. Dissertation, Univ New South Wales

Vakili A, Hebblewhite BK (2010) A new cavability assessment criterion for longwall top coal caving. Int J Rock Mech Min Sci 47:1317–1329

Wang C, Wang Y, Lu S (2000) Deformational behaviour of roadways in soft rocks in underground coal mines and principles for stability control. Int J Rock Mech Min Sci 37:937–946

Xie HP, Zhou HW, Xue DJ, Wang HW, Zhang R, Gao F (2012) Research and consideration on deep coal mining and critical mining depth. J China Coal Soc 37:535–542 (in Chinese)

Yan S, Bai JB, Wang XY, Huo LJ (2013) An innovative approach for gateroad layout in highly gassy longwall top coal caving. Int J Rock Mech Min Sci 59:33–41

Yavuz H (2004) An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int J Rock Mech Min Sci 41:193–205

Yavuz H, Fowell RJ (2001) FDM prediction of a yield pillar performance in conjunction with a field trial. In: Proceeding of 20th international conference on ground control in mining, West Virginia University, Morgantown, WV, pp 78–85

Yu JW, Zhu CQ (2011) Analysis on the controllable factor sensitivity and stability of roadway driving along goaf. J Hunan Univ Sci Technol 26:21–27 (in Chinese)

Zhang MW, Shimada H, Sasaoka T, Matsui K, Dou LM (2013) Evolution and effect of the stress concentration and rock failure in the deep multi-seam coal mine. Environ Earth Sci. doi:10.1007/s12665-013-2985-8

Zheng XG, Yao ZG, Zhang N (2012) Stress distribution of coal pillar with gob-side entry driving in the process of excavation and mining. J Min Saf Eng 29:459–465 (in Chinese)

Zhou G, Li YS, Wu ZY (2005) Measurement of crustal stress and analysis of characteristic in Datun mining area. J China Coal Soc 30:314–318 (in Chinese)

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China through grant no. 51174195 and no. 51204166, Chinese National Programs for Fundamental Research and Development (973 Program) through grant no. 2013CB227905, and Graduate Student Research Innovation Project of the Ordinary University in Jiangsu Province (2013) through grant no. CXLX13_952. All support is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, M., Bai, J., Li, W. et al. Failure mechanism and control of deep gob-side entry. Arab J Geosci 8, 9117–9131 (2015). https://doi.org/10.1007/s12517-015-1904-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-015-1904-6