Abstract

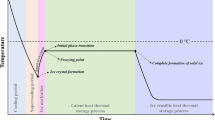

Freezing is one of the most effective and widely used preservation methods in the food industry. Freezing process means that the temperature of foods is reduced until the microbial growth and enzymatic activity are not possible; thus, the long-term preservation of foods is achieved. Since the rate of freezing is known to affect the distribution and size of ice crystals, the freezing rate is very important in the freezing process. In addition to the freezing process, it is known that the thawing process is also very important for the food quality. Similar to freezing, the rapid thawing method is preferred due to reduced weight loss, better texture, and prevention of microbial growth. For rapid freezing and thawing of food materials, various new technologies such as ultrasound, high pressure, and electric field are proposed instead of the traditional technologies currently used. These technologies provide to control ice crystal size, accelerate heat and mass transfer rates, and reduce tissue damage and weight loss. This review examines the effects of new technologies such as ultrasound, high-pressure, microwave, radiofrequency, magnetic field, and electric field on rapid freezing and thawing of foods while taking into account all the benefits and drawbacks. Additionally, this review is aimed to give guidance regarding the future research to enhance and, if required, combine current and developing technologies (high-pressure, ultrasound, microwave, radiofrequency, magnetic field, and electric field) to preserve foods with properties as near to fresh sample state as possible after freezing and thawing.

Similar content being viewed by others

Data Availability

Not applicable.

References

Becker BR, Fricke BA (1999) Evaluation of semi-analytical/empirical freezing time estimation methods part II: irregularly shaped food items. HVAC R Res 5:171–187. https://doi.org/10.1080/10789669.1999.10391231

Zhu Z, Zhou Q, Sun DW (2019) Measuring and controlling ice crystallization in frozen foods: a review of recent developments. Trends Food Sci Technol 90:13–25. https://doi.org/10.1016/j.tifs.2019.05.012

Jaeger M, Carin M, Medale M, Tryggvason G (1999) The osmotic migration of cells in a solute gradient. Biophys J 77:1257–1267. https://doi.org/10.1016/S0006-3495(99)76977-8

Saclier M, Peczalski R, Andrieu J (2010) Effect of ultrasonically induced nucleation on ice crystals’ size and shape during freezing in vials. Chem Eng Sci 65:3064–3071. https://doi.org/10.1016/j.ces.2010.01.035

Seon Mi Y, Jun Bo S, Kwang Il K et al (2015) Effects of various freezing and thawing techniques on pork quality in ready-to-eat meals. African J Food Sci 9:525–533. https://doi.org/10.5897/ajfs2015.1358

Bedane TF, Altin O, Erol B et al (2018) Thawing of frozen food products in a staggered through-field electrode radio frequency system: a case study for frozen chicken breast meat with effects on drip loss and texture. Innov Food Sci Emerg Technol 50:139–147. https://doi.org/10.1016/j.ifset.2018.09.001

Akhtar S, Khan MI, Faiz F (2013) Effect of thawing on frozen meat quality: a comprehensive review. Pakistan J Food Sci 23:198–211

Cai L, Cao M, Regenstein J, Cao A (2019) Recent advances in food thawing technologies. Compr Rev Food Sci Food Saf 18:953–970. https://doi.org/10.1111/1541-4337.12458

Uyar R, Bedane TF, Erdogdu F et al (2015) Radio-frequency thawing of food products — a computational study. J Food Eng 146:163–171. https://doi.org/10.1016/j.jfoodeng.2014.08.018

Li D, Zhu Z, Sun DW (2022) Effects of high-pressure freezing and deep-frozen storage on cell structure and quality of Cordyceps sinensis. Lwt 114044. https://doi.org/10.1016/j.lwt.2022.114044

Guo Z, Ge X, Yang L et al (2021) Ultrasound-assisted thawing of frozen white yak meat: effects on thawing rate, meat quality, nutrients, and microstructure. Ultrason Sonochem 70:105345. https://doi.org/10.1016/j.ultsonch.2020.105345

Sadot M, Curet S, Rouaud O et al (2017) Modélisation numérique d’un processus innovant de congélation assistée par micro-ondes. Int J Refrig 80:66–76. https://doi.org/10.1016/j.ijrefrig.2017.04.017

Hafezparast-Moadab N, Hamdami N, Dalvi-Isfahan M, Farahnaky A (2018) Effects of radiofrequency-assisted freezing on microstructure and quality of rainbow trout (Oncorhynchus mykiss) fillet. Innov Food Sci Emerg Technol 47:81–87. https://doi.org/10.1016/j.ifset.2017.12.012

Anese M, Manzocco L, Panozzo A et al (2012) Effect of radiofrequency assisted freezing on meat microstructure and quality. Food Res Int 46:50–54. https://doi.org/10.1016/j.foodres.2011.11.025

Tang J, Shao S, Tian C (2020) Effects of the magnetic field on the freezing process of blueberry. Int J Refrig 113:288–295. https://doi.org/10.1016/j.ijrefrig.2019.12.022

Lung CT, Chang CK, Cheng FC et al (2022) Effects of pulsed electric field-assisted thawing on the characteristics and quality of Pekin duck meat. Food Chem 390:133137. https://doi.org/10.1016/j.foodchem.2022.133137

Wang Q, Li Y, Sun DW, Zhu Z (2019) Effects of high-voltage electric field produced by an improved electrode system on freezing behaviors and selected properties of agarose gel. J Food Eng 254:25–33. https://doi.org/10.1016/j.jfoodeng.2019.02.024

Kumar PK, Rasco BA, Tang J, Sablani SS (2020) State/phase transitions, ice recrystallization, and quality changes in frozen foods subjected to temperature fluctuations. Food Eng Rev 12:421–451. https://doi.org/10.1007/s12393-020-09255-8

Kiani H, Sun DW (2011) Water crystallization and its importance to freezing of foods: a review. Trends Food Sci Technol 22:407–426. https://doi.org/10.1016/j.tifs.2011.04.011

Delgado AE, Sun DW (2001) Heat and mass transfer models for predicting freezing processes — a review. J Food Eng 47:157–174. https://doi.org/10.1016/S0260-8774(00)00112-6

Yu S, Ma Y, Zheng X et al (2012) Impacts of low and ultra-low temperature freezing on retrogradation properties of rice amylopectin during storage. Food Bioprocess Technol 5:391–400. https://doi.org/10.1007/s11947-011-0526-6

Zheng L, Sun DW (2006) Innovative applications of power ultrasound during food freezing processes — a review. Trends Food Sci Technol 17:16–23. https://doi.org/10.1016/j.tifs.2005.08.010

Alvarez MD, Canet W (1998) Effect of temperature fluctuations during frozen storage on the quality of potato tissue (cv. Monalisa). Eur Food Res Technol 206:52–57

Bustabad OM (1999) Weight loss during freezing and the storage of frozen meat. J Food Eng 41:1–11. https://doi.org/10.1016/S0260-8774(99)00065-5

Suplicz A, Szabo F, Kovacs JG (2013) Injection molding of ceramic filled polypropylene: the effect of thermal conductivity and cooling rate on crystallinity. Thermochim Acta 574:145–150. https://doi.org/10.1016/j.tca.2013.10.005

Lind I (1991) Mathematical modelling of the thawing process. J Food Eng 14:1–23. https://doi.org/10.1016/0260-8774(91)90051-S

Fadiji T, Ashtiani SHM, Onwude DI et al (2021) Finite element method for freezing and thawing industrial food processes. Foods 10:1–23. https://doi.org/10.3390/foods10040869

Ramaswamy HS, Tung MA (1984) A review on predicting freezing times of foods. J Food Process Eng 7:169–203. https://doi.org/10.1111/j.1745-4530.1984.tb00302.x

Wang J, Pham QT, Cleland DJ (2010) Freezing, thawing and chilling of foods. Mathematical Modeling of Food Processing, 375–398

Góral D, Kluza F, Spiess WEL, Kozłowicz K (2016) Review of thawing time prediction models depending on process conditions and product characteristics. Food Technol Biotechnol 54:3–12. https://doi.org/10.17113/ftb.54.01.16.4108

López-Leiva M, Hallström B (2003) The original Plank equation and its use in the development of food freezing rate predictions. J Food Eng 58:267–275. https://doi.org/10.1016/S0260-8774(02)00385-0

Cleland AC, Earle RL (1979) A comparison of methods for predicting the freezing times of cylindrical and spherical foodstuffs. J Food Sci 44:958–963. https://doi.org/10.1111/j.1365-2621.1979.tb03422.x

Cleland AC, Earle RL (1977) A comparison of analytical and numerical methods of predicting the freezing times of foods. J Food Sci 42:1390–1395. https://doi.org/10.1111/j.1365-2621.1977.tb14506.x

Plank R (1913) Betraohtungen über dynamisohe Zugbeanspruohung. Springer, Berlin Heidelberg, 21–45

Plank CJ (1942) The effect of dielectric constant on the rate of inversion of sucrose (Doctoral dissertation, Purdue University)

Nagaoka J, Takagi S, Hotani S (1955) Experiments on the freezing of fish by the air-blast freezer. Proceedings of the IX International Congress of Refrigeration, vol. 2

Luikov AV (1968) Analytical heat difusion theory. Academic Press, New York, NY

Cleland DJ, Cleland AC, Earle RL, Byrne SJ (1986) Prediction of thawing times for foods of simple shape. Int J Refrig 9:220–228. https://doi.org/10.1016/0140-7007(86)90094-0

Cleland DJ, Cleland AC, Earle RL (1986) Prediction of freezing and thawing times for foods — a review. Int J Refrig 9:182. https://doi.org/10.1016/0140-7007(86)90073-3

Cleland AC, Earle RL (1977) The third kind of boundary condition in numerical freezing calculations. Int J Heat Mass Transf 20:1029–1034. https://doi.org/10.1016/0017-9310(77)90187-9

Cleland AC, Earle RL (1979) Prediction of freezing times for foods in rectangular packages. J Food Sci 44:964–970. https://doi.org/10.1111/j.1365-2621.1979.tb03423.x

De Michelis A, Calvelo A (1982) Mathematical models for nonsymmetric freezing of beef. J Food Sci 47:1211–1217. https://doi.org/10.1111/j.1365-2621.1982.tb07650.x

Pham QT (1986) Simplified equation for predicting the freezing time of foodstuffs. Int J Food Sci Technol 21:209–219. https://doi.org/10.1111/j.1365-2621.1986.tb00442.x

Pham QT (1984) Extension to Planck’s equation for predicting freezing times of foodstuffs of simple shapes. Int J Refrig 7:377–383. https://doi.org/10.1016/0140-7007(84)90008-2

Pham QT (1985) Analytical method for predicting freezing times of rectangular blocks of foodstuffs. Int J Refrig 8:43–47. https://doi.org/10.1016/0140-7007(85)90143-4

Salvadori VO, Mascheroni RH (1991) Prediction of freezing and thawing times of foods by means of a simplified analytical method. J Food Eng 13:67–78. https://doi.org/10.1016/0260-8774(91)90038-T

Zhan X, Sun DW, Zhu Z, Wang QJ (2018) Improving the quality and safety of frozen muscle foods by emerging freezing technologies: a review. Crit Rev Food Sci Nutr 58:2925–2938. https://doi.org/10.1080/10408398.2017.1345854

Kayguluoğlu A (2018) sofralik siyah zeytin kalitesi üzerine acilik giderme işlemlerinin etkisi Aytül Kayguluoğlu

Çurkan A, Tamer CE, Çopur ÖU (2011) Dondurulmuş Meyve - Sebze İhracatının Analizi 82:73–82

Cai L, Dai Y, Cao M (2020) The effects of magnetic nanoparticles combined with microwave or far infrared thawing on the freshness and safety of red seabream (Pagrus major) fillets. Lwt 128:109456. https://doi.org/10.1016/j.lwt.2020.109456

Liao X, Xiang Q, Cullen PJ et al (2020) Plasma-activated water (PAW) and slightly acidic electrolyzed water (SAEW) as beef thawing media for enhancing microbiological safety. Lwt 117. https://doi.org/10.1016/j.lwt.2019.108649

Anderson BA, Sun S, Erdogdu F, Singh RP (2004) Thawing and freezing of selected meat products in household refrigerators. Int J Refrig 27:63–72. https://doi.org/10.1016/S0140-7007(03)00093-8

Zhang Y, Li S, Jin S et al (2021) Radio frequency tempering multiple layers of frozen tilapia fillets: the temperature distribution, energy consumption, and quality. Innov Food Sci Emerg Technol 68:102603. https://doi.org/10.1016/j.ifset.2021.102603

Backi CJ (2018) Methods for (industrial) thawing of fish blocks: a review. J Food Process Eng 41. https://doi.org/10.1111/jfpe.12598

Brown T, Evans JA, James C et al (2006) Thawing of cook-freeze catering packs. J Food Eng 74:70–77. https://doi.org/10.1016/j.jfoodeng.2005.02.016

Sun Q, Zhao X, Zhang C et al (2019) Ultrasound-assisted immersion freezing accelerates the freezing process and improves the quality of common carp (Cyprinus carpio) at different power levels. Lwt 108:106–112. https://doi.org/10.1016/j.lwt.2019.03.042

Woo MW, Mujumdar AS (2010) Effects of electric and magnetic field on freezing and possible relevance in freeze drying. Dry Technol 28:433–443. https://doi.org/10.1080/07373930903202077

Xanthakis E, Le-Bail A, Ramaswamy H (2014) Development of an innovative microwave assisted food freezing process. Innov Food Sci Emerg Technol 26:176–181. https://doi.org/10.1016/j.ifset.2014.04.003

Awad TS, Moharram HA, Shaltout OE et al (2012) Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res Int 48:410–427. https://doi.org/10.1016/j.foodres.2012.05.004

Ergün AR, Baysal T, Bozkır H (2013) Ultrases Yöntemi ile Karatenoitlerin Ekstraksiyonu Gıda 38:239–246. https://doi.org/10.5505/gida.2013.30074

Dolatowski ZJ, Stadnik J, Stasiak D (2007) Applications of ultrasound in food technology. ACTA Sci Pol 63:89–99

Jambrak AR, Herceg Z, Šubarić D et al (2010) Ultrasound effect on physical properties of corn starch. Carbohydr Polym 79:91–100. https://doi.org/10.1016/j.carbpol.2009.07.051

Demirdöven A, Baysal T (2009) The use of ultrasound and combined technologies in food preservation. Food Rev Int 25:1–11. https://doi.org/10.1080/87559120802306157

Cheng X, Zhang M, Xu B et al (2015) The principles of ultrasound and its application in freezing related processes of food materials: a review. Ultrason Sonochem 27:576–585. https://doi.org/10.1016/j.ultsonch.2015.04.015

Li B, Sun DW (2002) Effect of power ultrasound on freezing rate during immersion freezing of potatoes. J Food Eng 55:277–282. https://doi.org/10.1016/S0260-8774(02)00102-4

Simal S, Benedito J, Sánchez ES, Rosselló C (1998) Use of ultrasound to increase mass transport rates during osmotic dehydration. J Food Eng 36:323–336. https://doi.org/10.1016/S0260-8774(98)00053-3

Qiu L, Zhang M, Chitrakar B, Bhandari B (2020) Application of power ultrasound in freezing and thawing processes: effect on process efficiency and product quality. Ultrason Sonochem 68. https://doi.org/10.1016/j.ultsonch.2020.105230

Piyasena P, Mohareb E, McKellar RC (2003) Inactivation of microbes using ultrasound: a review. Int J Food Microbiol 87:207–216. https://doi.org/10.1016/S0168-1605(03)00075-8

Knorr D, Zenker M, Heinz V, Lee DU (2004) Applications and potential of ultrasonics in food processing. Trends Food Sci Technol 15:261–266. https://doi.org/10.1016/j.tifs.2003.12.001

Gambuteanu C, Alexe P (2015) Comparison of thawing assisted by low-intensity ultrasound on technological properties of pork longissimus dorsi muscle. J Food Sci Technol 52:2130–2138. https://doi.org/10.1007/s13197-013-1204-7

Zhang M, Xia X, Liu Q et al (2019) Changes in microstructure, quality and water distribution of porcine longissimus muscles subjected to ultrasound-assisted immersion freezing during frozen storage. Meat Sci 151:24–32. https://doi.org/10.1016/j.meatsci.2019.01.002

Zhu Z, Chen Z, Zhou Q et al (2018) Freezing efficiency and quality attributes as affected by voids in plant tissues during ultrasound-assisted immersion freezing. Food Bioprocess Technol 11:1615–1626. https://doi.org/10.1007/s11947-018-2103-8

Liu Y, Chen S, Pu Y et al (2019) Ultrasound-assisted thawing of mango pulp: effect on thawing rate, sensory, and nutritional properties. Food Chem 286:576–583. https://doi.org/10.1016/j.foodchem.2019.02.059

Sun Q, Sun F, Xia X et al (2019) The comparison of ultrasound-assisted immersion freezing, air freezing and immersion freezing on the muscle quality and physicochemical properties of common carp (Cyprinus carpio) during freezing storage. Ultrason Sonochem 51:281–291. https://doi.org/10.1016/j.ultsonch.2018.10.006

Li X, Chen W, Jiang J et al (2019) Functionality of dairy proteins and vegetable proteins in nutritional supplement powders: a review. Int Food Res J 26:1651–1664

Zhang C, Sun Q, Chen Q et al (2020) Effects of ultrasound-assisted immersion freezing on the muscle quality and physicochemical properties of chicken breast. Int J Refrig 117:247–255. https://doi.org/10.1016/j.ijrefrig.2020.05.006

Li D, Zhao H, Muhammad AI et al (2020) The comparison of ultrasound-assisted thawing, air thawing and water immersion thawing on the quality of slow/fast freezing bighead carp (Aristichthys nobilis) fillets. Food Chem 320:126614. https://doi.org/10.1016/j.foodchem.2020.126614

Balasubramaniam VMB, Martínez-Monteagudo SI, Gupta R (2015) Principles and application of high pressure-based technologies in the food industry. Annu Rev Food Sci Technol 6:435–462. https://doi.org/10.1146/annurev-food-022814-015539

Wu XF, Zhang M, Adhikari B, Sun J (2017) Recent developments in novel freezing and thawing technologies applied to foods. Crit Rev Food Sci Nutr 57:3620–3631. https://doi.org/10.1080/10408398.2015.1132670

Cheng L, Sun DW, Zhu Z, Zhang Z (2017) Effects of high pressure freezing (HPF) on denaturation of natural actomyosin extracted from prawn (Metapenaeus ensis). Food Chem 229:252–259. https://doi.org/10.1016/j.foodchem.2017.02.048

Cheng L, Zhu Z, Sun DW (2021) Impacts of high pressure assisted freezing on the denaturation of polyphenol oxidase. Food Chem 335:127485. https://doi.org/10.1016/j.foodchem.2020.127485

Li W, Wang P, Xu X et al (2014) Use of low-field nuclear magnetic resonance to characterize water properties in frozen chicken breasts thawed under high pressure. Eur Food Res Technol 239:183–188. https://doi.org/10.1007/s00217-014-2189-9

Cui Y, Xuan X, Ling J et al (2019) Effects of high hydrostatic pressure-assisted thawing on the physicohemical characteristics of silver pomfret (Pampus argenteus). Food Sci Nutr 7:1573–1583. https://doi.org/10.1002/fsn3.966

Jia F, Jing Y, Dai R et al (2020) High-pressure thawing of pork: water holding capacity, protein denaturation and ultrastructure. Food Biosci 38:100688. https://doi.org/10.1016/j.fbio.2020.100688

Peng Y, Zhao J, Wen X, Ni Y (2022) The comparison of microwave thawing and ultra-high-pressure thawing on the quality characteristics of frozen mango. Foods 11. https://doi.org/10.3390/foods11071048

Chandrasekaran S, Ramanathan S, Basak T (2013) Microwave food processing—a review. Food Res Int 52:243–261. https://doi.org/10.1016/j.foodres.2013.02.033

Orlowska M, Havet M, Le-Bail A (2009) Controlled ice nucleation under high voltage DC electrostatic field conditions. Food Res Int 42:879–884. https://doi.org/10.1016/j.foodres.2009.03.015

Jha PK, Chevallier S, Xanthakis E et al (2020) Effect of innovative microwave assisted freezing (MAF) on the quality attributes of apples and potatoes. Food Chem 309:125594. https://doi.org/10.1016/j.foodchem.2019.125594

Altin O, Skipnes D, Skåra T, Erdogdu F (2022) A computational study for the effects of sample movement and cavity geometry in industrial scale continuous microwave systems during heating and thawing processes. Innov Food Sci Emerg Technol 77. https://doi.org/10.1016/j.ifset.2022.102953

Phinney DM, Frelka JC, Wickramasinghe A, Heldman DR (2017) Effect of freezing rate and microwave thawing on texture and microstructural properties of potato (Solanum tuberosum). J Food Sci 82:933–938. https://doi.org/10.1111/1750-3841.13690

Liu C, Deng H, Chen X et al (2020) Impact of rock samples size on the microstructural changes induced by freeze–thaw cycles. Rock Mech Rock Eng 53:5293–5300. https://doi.org/10.1007/s00603-020-02201-4

Zhang Y, Pandiselvam R, Zhu H et al (2022) Impact of radio frequency treatment on textural properties of food products: an updated review. Trends Food Sci Technol 124:154–166. https://doi.org/10.1016/j.tifs.2022.04.014

Manzocco L, Alongi M, Cortella G, Anese M (2022) Optimizing radiofrequency assisted cryogenic freezing to improve meat microstructure and quality. J Food Eng 335:111184. https://doi.org/10.1016/j.jfoodeng.2022.111184

Llave Y, Erdogdu F (2022) Radio frequency processing and recent advances on thawing and tempering of frozen food products. Crit Rev Food Sci Nutr 62:598–618. https://doi.org/10.1080/10408398.2020.1823815

Watanabe T, Ando Y (2021) Evaluation of heating uniformity and quality attributes during vacuum microwave thawing of frozen apples. Lwt 150:111997. https://doi.org/10.1016/j.lwt.2021.111997

Atani SH, Hamdami N, Dalvi-Isfahan M et al (2022) Effects of microwave-assisted freezing on the quality attributes of lamb meat. Int J Refrig 143:192–198. https://doi.org/10.1016/j.ijrefrig.2022.03.019

Wang B, Du X, Kong B et al (2020) Effect of ultrasound thawing, vacuum thawing, and microwave thawing on gelling properties of protein from porcine longissimus dorsi. Ultrason Sonochem 64:104860. https://doi.org/10.1016/j.ultsonch.2019.104860

Choi EJ, Park HW, Chung YB et al (2017) Effect of tempering methods on quality changes of pork loin frozen by cryogenic immersion. Meat Sci 124:69–76. https://doi.org/10.1016/j.meatsci.2016.11.003

Yang H, Chen Q, Cao H et al (2019) Radiofrequency thawing of frozen minced fish based on the dielectric response mechanism. Innov Food Sci Emerg Technol 52:80–88. https://doi.org/10.1016/j.ifset.2018.10.013

Kaur M, Kumar M (2019) An innovation in magnetic field assisted freezing of perishable fruits and vegetables: a review. Food Rev Int 36:761–780. https://doi.org/10.1080/87559129.2019.1683746

Tang J, Zhang H, Tian C, Shao S (2020) Effects of different magnetic fields on the freezing parameters of cherry. J Food Eng 278:109949. https://doi.org/10.1016/j.jfoodeng.2020.109949

Panayampadan AS, Shafiq Alam M, Aslam R et al (2022) Effects of alternating magnetic field on freezing of minimally processed guava. Lwt 163:113544. https://doi.org/10.1016/j.lwt.2022.113544

Tang J, Shao S, Tian C (2019) Effects of the magnetic field on the freezing parameters of the pork. Elsevier Ltd

Mohsenpour M, Nourani M, Enteshary R (2023) Effect of thawing under an alternating magnetic field on rainbow trout (Oncorhynchus mykiss) fillet characteristics. Food Chem 402. https://doi.org/10.1016/j.foodchem.2022.134255

Otero L, Pozo A (2022) Effects of the application of static magnetic fields during potato freezing. J Food Eng 316:110838. https://doi.org/10.1016/j.jfoodeng.2021.110838

Leng D, Zhang H, Tian C et al (2022) The effect of magnetic field on the quality of channel catfish under two different freezing temperatures. Int J Refrig 140:49–56. https://doi.org/10.1016/j.ijrefrig.2022.05.008

Dalvi-Isfahan M, Hamdami N, Le-Bail A (2016) Effect of freezing under electrostatic field on the quality of lamb meat. Innov Food Sci Emerg Technol 37:68–73. https://doi.org/10.1016/j.ifset.2016.07.028

Jha PK, Xanthakis E, Jury V et al (2018) Advances of electro-freezing in food processing. Curr Opin Food Sci 23:85–89. https://doi.org/10.1016/j.cofs.2018.06.007

Jha PK, Xanthakis E, Jury V, Le-Bail A (2017) An overview on magnetic field and electric field interactions with ice crystallisation; application in the case of frozen food. Crystals 7. https://doi.org/10.3390/cryst7100299

Xanthakis E, Havet M, Chevallier S et al (2013) Effect of static electric field on ice crystal size reduction during freezing of pork meat. Innov Food Sci Emerg Technol 20:115–120. https://doi.org/10.1016/j.ifset.2013.06.011

Li J, Shi J, Huang X et al (2020) Effects of pulsed electric field on freeze-thaw quality of Atlantic salmon. Innov Food Sci Emerg Technol 65. https://doi.org/10.1016/j.ifset.2020.102454

Jia G, Sha K, Meng J, Liu H (2019) Effect of high voltage electrostatic field treatment on thawing characteristics and post-thawing quality of lightly salted, frozen pork tenderloin. Elsevier Ltd

Alkanan ZT, Altemimi AB, Al-Hilphy ARS et al (2021) Ohmic heating in the food industry: developments in concepts and applications during 2013–2020. Appl Sci 11. https://doi.org/10.3390/app11062507

Çokgezme ÖF, Döner D, Çevik M et al (2021) Influences of sample shape, voltage gradient, and electrode surface form on the exergoeconomic performance characteristics of ohmic thawing of frozen minced beef. J Food Eng 307. https://doi.org/10.1016/j.jfoodeng.2021.110660

Xie Y, Chen B, Guo J et al (2021) Effects of low voltage electrostatic field on the microstructural damage and protein structural changes in prepared beef steak during the freezing process. Meat Sci 179:108527. https://doi.org/10.1016/j.meatsci.2021.108527

Jiang Q, Zhang M, Mujumdar AS, Chen B (2022) Comparative freezing study of broccoli and cauliflower: effects of electrostatic field and static magnetic field. Food Chem 397:133751. https://doi.org/10.1016/j.foodchem.2022.133751

Hu F, Qian S, Huang F et al (2021) Combined impacts of low voltage electrostatic field and high humidity assisted-thawing on quality of pork steaks. Lwt 150:111987. https://doi.org/10.1016/j.lwt.2021.111987

Hu R, Zhang M, Mujumdar AS (2022) Novel assistive technologies for efficient freezing of pork based on high voltage electric field and static magnetic field: a comparative study. Innov Food Sci Emerg Technol 80:103087. https://doi.org/10.1016/j.ifset.2022.103087

Zhang Y, Ding C (2020) The study of thawing characteristics and mechanism of frozen beef in high voltage electric field. IEEE Access 8:134630–134639. https://doi.org/10.1109/ACCESS.2020.3010948

Rahbari M, Hamdami N, Mirzaei H et al (2018) Effects of high voltage electric field thawing on the characteristics of chicken breast protein. J Food Eng 216:98–106. https://doi.org/10.1016/j.jfoodeng.2017.08.006

Zhang R, Ding F, Zhang Y et al (2022) Freezing characteristics and relative permittivity of rice flour gel in pulsed electric field assisted freezing. Food Chem 373:131449. https://doi.org/10.1016/j.foodchem.2021.131449

Cevik M, Icier F (2018) Effects of voltage gradient and fat content on changes of electrical conductivity of frozen minced beef meat during ohmic thawing. J Food Process Eng 41. https://doi.org/10.1111/jfpe.12675

Çabas BM, Azazi I, Döner D et al (2022) Comparative performance analysis of ohmic thawing and conventional thawing of spinach puree. J Food Process Eng 45:1–8. https://doi.org/10.1111/jfpe.14015

Funding

This study is supported by the Scientific Research Projects of Ege University (BAP-24168 and BAP-23504), TUBITAK-2244/119C097, and Vestel Beyaz Eşya San. ve Tic. A.Ş.

Author information

Authors and Affiliations

Contributions

Özgün Köprüalan Aydın: methodology, writing, review and editing. Hira Yüksel: methodology, writing, review and editing. Safiye Nur Dirim: methodology, writing, review and editing, supervision. Figen Kaymak Ertekin: methodology, writing, review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Köprüalan Aydın, Ö., Yüksel Sarıoğlu, H., Dirim, S.N. et al. Recent Advances for Rapid Freezing and Thawing Methods of Foods. Food Eng Rev 15, 667–690 (2023). https://doi.org/10.1007/s12393-023-09356-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09356-0