Abstract

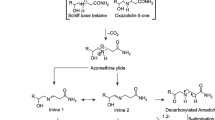

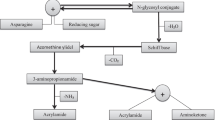

In April 2002, unexpectedly high levels of the neurotoxic and suspected carcinogen acrylamide were found in many heated foods, represented mainly by cereal and potato derivatives. Acrylamide can be formed during intense heat treatments as a consequence of the reaction between asparagine and a carbonyl source via Maillard-type reactions. Efforts by the scientific community have contributed to the identification of potential routes to reduce acrylamide levels in foods, and consequently, consumer intake. The main mitigations strategies, which can be applied to lower acrylamide content, include agronomical (i.e., selection of raw materials with low sugar and asparagine contents) and technological interventions (e.g., pretreatments, process, and formulation changes). This review explores the most reliable and potentially exploitable technological strategies for acrylamide reduction in food products. In order for an industrial process to be feasible it has to comply with the compatibility requisites of the existing process, as well as have low impact on sensory and nutritional properties of foods, regulatory compliance, and limited costs. In this regard, an innovative approach of physical removal of acrylamide from the finished product is also discussed.

Similar content being viewed by others

References

Ahrné L, Andersson C-G, Floberg P et al (2007) Effect of crust temperature and water content on acrylamide formation during baking of white bread: steam and falling temperature baking. Lebensm Wiss Technol 40:1708–1715

Amrein TM, Bachmann S, Noti A et al (2003) Potential of acrylamide formation, sugars, and free asparagine in potatoes: a comparison of cultivars and farming systems. J Agric Food Chem 51:5556–5560

Amrein TM, Schoenbaechler B, Escher F, Amadò R (2004) Acrylamide in gingerbread: critical factors for formation and possible ways for reduction. J Agric Food Chem 52:4282–4288

Amrein TM, Escher F, Amadò R (2006) Controlling acrylamide formation during baking. In: Skog K, Alexander J (eds) Acrylamide and other hazardous compounds in heat-treated foods. Woodhead, Cambridge

Anese M, Manzocco L, Maltini E (2005) Effect of coffee physical structure on volatile release. Eur Food Res Technol 221:434–438

Anese M, Sovrano S, Bortolomeazzi R (2008) Effect of radiofrequency heating on acrylamide formation in bakery products. Eur Food Res Technol 226:1197–1203

Anese M, Bortolomeazzi R, Manzocco L et al (2009) Effect of chemical and biological dipping on acrylamide formation and sensory properties in deep-fried potatoes. Food Res Int 42:142–147

Anese M, Suman M, Nicoli MC (2009) Physical removal of acrylamide from heated foods. Food Chem. doi:10.1016/j.foodchem.2009.06.043

Baardseth P, Blom H, Skrede G et al (2006) Lactic acid fermentation reduces acrylamide formation and other Maillard reactions in French fries. J Food Sci 71:C28–C33

Becalski A, Lau BP-L, Lewis D et al (2003) Acrylamide in foods: occurrence, sources and modeling. J Agric Chem 51:802–808

Biedermann M, Grob K (2003) Model studies on acrylamide formation in potato, wheat flour and corn starch; ways to reduce acrylamide content in bakery ware. Mitt Lebensm Hyg 94:406–422

Biedermann M, Noti A, Biedermann-Bremm S et al (2002) Experiments on acrylamide formation and possibilities to decrease the potential of acrylamide formation in potatoes. Mitt Lebensm Hyg 93:668–687

Bråthen E, Knutsen SH (2005) Effect of temperature and time on the formation of acrylamide in starch-based and cereal model systems, flat breads and bred. Food Chem 92:693–700

Bråthen E, Kita A, Knutsen SH et al (2005) Addition of glycine reduces the content of acrylamide in cereal and potato products. J Agric Chem 53:3259–3264

Budavari S, O’Neil MJ, Smith A et al (1989) The Merck index. The Merck Index & Co Inc, Whitehouse Station

CIAA (2007) The CIAA acrylamide toolbox. Confederation of the Food and Drink industries. www.ciaa.be. Accessed 13 Feb 2009

Ciesarová Z, Kiss E, Boegl P (2006) Impact of L-asparaginase on acrylamide content in potato products. J Food Nutr Res 45:141–146

Ciesarova Z, Suhaj M, Horvathova J (2008) Correlation between acrylamide contents and antioxidant capacities of spice extracts in a model potato matrix. J Food Nutr Res 47:1–5

Claeys WL, De Vleeschouwer K, Hendrickx ME (2005) Quantifying the formation of carcinogens during food processing: acrylamide. Trends Food Sci Technol 16:181–193

Claus A, Carle R, Schieber A (2008) Acrylamide in cereal products: a review. J Cereal Sci 47:118–133

Claus A, Mongili M, Weisz G et al (2008) Impact of formulation and technological factors on the acrylamide content of wheat bread and bread rolls. J Cereal Sci 7:546–554

Cook DJ, Taylor AJ (2005) On-line Ms/MS monitoring of acrylamide generation in potato- and cereal-based systems. J Agric Food Chem 53:8926–8933

Corrigan PJ (2008) Methods for reducing asparagine in a dough food component using water activity. US patent 20080166450-A1

de Boer L (2008) Novel process for enzymatic acrylamide reduction in food products. Patent No. EP1896576-A1

EFSA European Food Safety Authority (2008) Scientific Colloquium No 11: acrylamide carcinogenicity. New evidence in relation to dietary exposure, 22–23 May 2008, Tabiano, Italy

Elder VA, Fulcher JG, Leung HKH (2006) Method for reducing acrylamide formation in thermally processed foods. US Patent 20060127534-A1

Elder VA, Fulcher JG, Kin-Hang Leung H et al (2007) Methods for reducing acrylamide. US Patent 20070141225-A1

Elmore JS, Koutsidis G, Dodson AT (2005) Measurement of acrylamide and its precursors in potato, wheat, and rye model systems. J Agric Food Chem 53:1286–1293

Erdoğdu SB, Palazoğlu TK, Gökmen V et al (2007) Reduction of acrylamide formation in French fries by microwave pre-cooking of potato strips. J Sci Food Agric 87:133–137

FDA, Center for Food Safety and Applied Nutrition (2006) http://www.cfsan.fda.gov/~lrd/pestadd.html#acrylamide. Accessed 13 Feb 2009

Fellows PJ (2000) Food processing technology. Woodhead, Cambridge

Fernandez S, Kurppa L, Hyvonen L (2003) Content of acrylamide decreased in potato chips with addition of a proprietary flavonoid spice mix (Flavomare®) in frying. Innov Food Technol 18:24–26

Fiselier K, Bazzocco D, Gama-Baumgartner F et al (2006) Influence of the frying temperature on acrylamide formation in French fries. Eur Food Res Technol 222:414–419

Flink J (1975) The retention of volatile components during freeze-drying: a structurally based mechanism. In: Goldblith SA, Rey L, Rothmayr WW (eds) Freeze drying and advanced food technology. Academic Press, London

Flink J, Karel M (1970) Effects of process variables on retention of volatiles in freeze-drying. J Food Sci 35:444–447

Flink J, Karel M (1970) Retention of organic volatiles in freeze-dried solutions of carbohydrates. J Agric Food Chem 18:295–297

Fredriksson H, Tallving J, Rosen J et al (2004) Fermentation reduces free asparagine in dough and acrylamide content in bread. Cereal Chem 81:650–653

Friedman M (2003) Chemistry, biochemistry, and safety of acrylamide. A review. J Agric Food Chem 51(16):4504–4526

Friedman M, Levin CE (2008) Review of methods for the reduction of dietary content and toxicity of acrylamide. J Agric Food Chem 56:6113–6140

FSTA Food Science and Technology Abstracts (2008) http://www.isiknowledge.com. Accessed 16 Feb 2009

Gama-Baumgartner F, Grob K, Biedermann M (2004) Citric acid to reduce acrylamide formation in French fries and roasted potatoes? Mitt Lebensm Hyg 95:110–117

Gökmen V, Şenyuva HZ (2007) Acrylamide formation is prevented by divalent cations during the Maillard reaction. Food Chem 103:196–203

Gökmen V, Açar OC, Köksel H et al (2007) Effects of dough formula and baking conditions on acrylamide and hydroxymethylfurfural formation in cookies. Food Chem 104:1136–1142

Graf M, Amrein TM, Graf S et al (2006) Reducing the acrylamide content of a semi-finished biscuit on industrial scale. Lebensm Wiss Technol 39:724–728

Granda C, Moreira RG, Tichy SE (2004) Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. J Food Sci 69:E405–E411

Haase NU, Matthaus B, Vosmann K (2003) Acrylamide formation in foodstuffs—minimizing strategies for potato crisps. Dtsch Lebensm Rund 99:87–90

He F, Zhang S, Wang H (1989) Neurological and electroneuromicrographic assessment of the adverse effects of acrylamide on occupationally exposed Scandinavian workers. J Work Environ Health 15:125–129

Hedegaard RV, Frandsen H, Granby K et al (2007) Model studies on acrylamide generation from glucose/asparagine in aqueous glycerol. J Agric Food Chem 55:486–492

IARC (1994) IARC monographs on the evaluation of carcinogenic risks to humans, vol 60. International Agency for Research on Cancer, Lyon

IRMM (2005) EU database on acrylamide levels in food. www.irmm.jrc.be/htlm/acrivities/acrylamide/database/htm. Accessed 10 March 2009

JEFCA (2007) Monograph 4. www.fao.org/ag/jefca-additives/specs/monograph4/additive-498-m4.pdf. Accessed 13 Feb 2009

Kita A, Brathen E, Knusten SH et al (2004) Effective ways of decreasing acrylamide content in potato crisp during processing. J Agric Food Chem 52:7011–7016

Kolek E, Simko P, Simon P (2006) Inhibition of acrylamide formation in asparagine/D-glucose model systems by NaCl addition. Eur Food Res Technol 224:283–284

Kolek E, Šimon P, Šimko P (2007) Nonisothermal kinetics of acrylamide elimination and its acceleration by table salt—a model study. J Food Sci 72:E341–E344

Kuilman M, Wilms L (2007) Safety of the enzyme asparaginase, a means of reduction of acrylamide in food. Toxicol Lett 172:S196–S197

Levine RS, Smith RE (2005) Sources of variability of acrylamide levels in cracker model. J Agric Food Chem 53:4410–4416

Lingnert H, Grivas S, Jägerstad M et al (2002) Acrylamide in food: mechanisms of formation and influencing factors during heating of foods. Scand J Nutr 46:159–172

LoPachin RM, Ross JF, Lehning EJ (2002) Nerve terminals as the primary site of acrylamide action. Neurotoxicology 23:43–59

Low MY, Koutsidis G, Parker JK et al (2006) Effect of citric acid and glycine addition on acrylamide and flavor in a potato model system. J Agric Food Chem 54:5976–5983

Mestdagh F, De Meulenaer B, Cucu T et al (2006) Role of water upon the formation of acrylamide in a potato model system. J Agric Food Chem 54:9092–9098

Mestdagh F, De Wilde T, Delporte K et al (2008) Impact of chemical pre-treatments on the acrylamide formation and sensorial quality of potato crisps. Food Chem 106:914–922

Mottram DS, Wedzicha BL, Dodson AT (2002) Acrylamide is formed in the Maillard reaction. Nature 419:448

Mustafa A, Andersson R, Rosén J et al (2005) Factors influencing acrylamide content and color in rye crisp bread. J Agric Food Chem 53:5985–5989

Nicoli MC, Anese M (2006) A process for removing acrylamide from foods. Patent No. PD2006A000332

Pedreschi F, Kaack K, Granby K (2008) The effect of asparaginase on acrylamide formation in French fries. Food Chem 109:386–392

Rifa MK, Voilley A (1991) Collapse and aroma retention during storage of freeze-dried products. J Food Sci Technol 28:135–137

Romani S, Bacchiocca M, Rocculi P et al (2008) Effect of frying time on acrylamide content and quality aspects of French fries. Eur Food Res Technol 226:555–560

Rutherfurd SM, Moughan PJ (1998) The digestible amino acid composition of several milk proteins: application of a new bioassay. J Dairy Sci 81:909–917

Rydberg P, Eriksson S, Tareke E et al (2003) Investigations of factors that influence the acrylamide content of heated foodstuffs. J Agric Food Chem 51:7012–7018

Rydberg P, Eriksson S, Tareke E et al (2005) Factors that influence the acrylamide content of heated foods. In: Friedman M, Mottram DS (eds) Chemistry and safety of acrylamide in food. Springer, New York

Sadd P, Hamlet C (2005) The formation of acrylamide in UK cereal products. In: Friedman M, Mottram DS (eds) Chemistry and safety of acrylamide in food. Springer, New York

Sadd P, Hamlet CG, Liang L (2008) Effectiveness of methods for reducing acrylamide in bakery products. J Agric Food Chem 56:6154–6161

Springer M, Fisher T, Lehrack A et al (2003) Acrylamidbildung in Backwaren. Getreide Mehl Brot 57:274–278

Stadler RH, Scholz G (2004) Acrylamide: an update on current knowledge in analysis, levels in food, mechanisms of formation, and potential strategies of control. Nutr Rev 62:449–467

Stadler RH, Blank I, Varga N et al (2002) Acrylamide from Maillard reaction products. Nature 419:449

Surdyk N, Rosén J, Andersson R et al (2004) Effects of asparagine, fructose, and baking conditions on acrylamide content in yeast-leavened wheat bread. J Agric Food Chem 52:2047–2051

Taeymans D, Wood J, Ashby P et al (2004) A review of acrylamide: an industry perspective on research, analysis, formation and control. Crit Rev Food Sci Nutr 44:323–347

Tareke E (2003) Identification and origin of potential background carcinogens: endogenous isoprene and oxiranes, dietary acrylamide. PhD dissertation Department of Environmental Chemistry, Stockholm University

Tareke E, Rydberg P, Karlsson P et al (2002) Analysis of acrylamide, a carcinogen formed in heated foodstuffs. J Agric Food Chem 50:4998–5006

Taubert D, Harlfinger G, Henkes L et al (2004) Influence of processing parameters on acrylamide formation during frying of potatoes. J Agric Food Chem 52:2735–2739

Vang Hendriksen H, Stringer M, Ernst S et al (2006) Novoenzymes A/S. Patent No. WOO6053563

Vass M, Amrein TM, Schönbächler B et al (2004) Ways to reduce acrylamide formation in cracker production. Czech J Food Sci 22:19–21

Vattem DA, Shetty K (2003) Acrylamide in foods: a model for mechanism of formation and its reduction. Innov Food Sci Emerg Technol 4:331–338

Wedzicha BL, Mottram DS, Elmore JS et al (2005) Kinetic models as a route to control acrylamide formation in food. In: Friedman M, Mottram D (eds) Chemistry and safety of acrylamide in food. Springer, New York

Yaylayan VA, Stadler RH (2005) Acrylamide formation in food: a mechanistic perspective. J AOAC Int 88:262–267

Zhang Y, Zhang Y (2007) Formation and reduction of acrylamide in Maillard reaction: a review based on current state of knowledge. Crit Rev Food Sci Nutr 47:521–542

Zhang Y, Zhang Y (2008) Effect of natural antioxidants on kinetic behavior of acrylamide formation and elimination in low-moisture asparagine-glucose model system. J Food Eng 85:105–115

Zhaoyang L (2003) Process and apparatus for reducing residual level of acrylamide in heat processed food. US Patent 20030219518-A1

Zyzak DV, Sanders RA, Stojanovic M et al (2003) Acrylamide formation mechanism in heated foods. J Agric Food Chem 51(16):4782–4787

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anese, M., Suman, M. & Nicoli, M.C. Technological Strategies to Reduce Acrylamide Levels in Heated Foods. Food Eng. Rev. 1, 169–179 (2009). https://doi.org/10.1007/s12393-009-9008-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-009-9008-2