Abstract

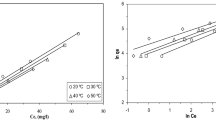

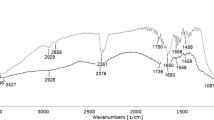

Sucrose crystallization process is greatly inhibited by high Na+, K+ and Ca2+ content in the crystallizing medium—sugar juice. In this study, unmodified pressed sugar beet pulp was used as a weak polyfunctional cation exchanger for the removal of Na+, K+ and Ca2+ from an alkalized sugar juice in a closed-loop column system. Cation removal effect was evaluated through the influence of temperature (30–70 °C), pH (8.5–12.5) and volume (150–300 ml) of alkalized juice. Sugar beet pulp exhibited the highest Ca2+ removal (56.58%) at 70 °C and pH value of 12.5, indicating strong impact of cation solubility, precipitation and valence. Milder conditions of alkalized sugar juice such as temperature (50 °C) and pH value (10.5) contributed to the maximum removal of Na+ (15.07%) and K+ (10.58%). Component analysis of the heteroporous sugar beet pulp with total porosity of 53% and specific surface area of 0.9 m2/g indicated hydroxyl and carboxyl groups as the main centers for an ion-exchange process in the material used, which was confirmed by FTIR analysis. This is the first time that unmodified pressed sugar beet pulp (PSBP) has been used as biosorbent for Na+, K+ and Ca2+ removal in a closed-loop column system.

Similar content being viewed by others

References

Altundogan, H.S., N.E. Arslan, and F. Tumen. 2007. Copper removal from aqueous solutions by sugar beet pulp treated by NaOH and citric acid. Journal of Hazardous Materials 149 (2): 432–439. https://doi.org/10.1016/j.jhazmat.2007.04.008.

Arslanoglu, H., and F. Tumen. 2012. A study on cations and color removal from thin sugar juice by modified sugar beet pulp. Journal of Food Science and Technology 49 (3): 319–327. https://doi.org/10.1007/s13197-011-0288-1.

Asadi, M. 2006. Beet-sugar handbook. USA, New Jersey: John Wiley & Sons.

Bellahsen, N., G. Varga, N. Halyag, S. Kertész, E. Tombácz, and C. Hodúr. 2021. Pomegranate peel as a new low-cost adsorbent for ammonium removal. International Journal of Environmental Science and Technology 18 (3): 711–722.

Campbell, L.G. 2002. Sugar beet quality improvement. Journal of Crop Production 5 (1–2): 395–413. https://doi.org/10.1300/J144v05n01_16.

Castro, L.M.L., F. Blázquez, J..A.. Muñoz. González, and A. Ballester. 2017. Biosorption of Zn(II) from industrial effluents using sugar beet pulp and F. Vesiculosus: from laboratory tests to a pilot approach. Science of the Total Environment 598: 856–866. https://doi.org/10.1016/j.scitotenv.2017.04.138.

CEFS Sugar Statistics. 2022. Comitee Europeen des fabricants de sucre. Brussels: Belgium.

CN107262050A. 2017. A kind of beet pulp biological adsorption agent and its preparation method and application. Chnise Patent.

Coca, M., S. Mato, G. González-Benito, M.A. Urueña, and M.T. García-Cubero. 2010. Use of weak cation exchange resin Lewatit S 8528 as alternative to strong ion exchange resins for calcium salt removal. Journal of Food Engineering 97 (4): 569–573.

Eastwood, M.A. 1974. Dietary fibre in human nutrition. Journal of the Science of Food and Agriculture 25 (12): 1523–1527.

Elsayed, M., Y. Andres, and W. Blel. 2022. Anaerobic co-digestion of linen, sugar beet pulp, and wheat straw with cow manure: effects of mixing ratio and transient change of co-substrate. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-021-02229-8.

SRPS EN ISO 6869/2008. 2008. Animal feeding stuffs–Determination of the contents of calcium, copper, iron, magnesium, manganese, potassium, sodium and zinc-Method using atomic absorption spectrometry. Institute for Standardization of Serbia, Belgrade.

Farnane, M., H. Tounsadi, R. Elmoubarki, F.Z. Mahjoubi, A. Elhalil, S. Saqrane, M. Abdennouri, S. Qourzal, and N. Barka. 2017. Alkaline treated carob shells as sustainable biosorbent for clean recovery of heavy metals: kinetics, equilibrium, ions interference and process optimisation. Ecological Engineering 101: 9–20. https://doi.org/10.1016/j.ecoleng.2017.01.012.

Gupta, S., M. Dey, S. Javaid, Y. Ji, and S. Payne. 2020. On the design of novel biofoams using lignin, wheat straw, and sugar beet pulp as precursor material. ACS Omega 5 (28): 17078–17089. https://doi.org/10.1021/acsomega.0c00721.

Jahed, E., M.H.H. Khodaparast, and A. Mousavi Khaneghah. 2014. Bentonite, temperature and pH effects on purification indexes of raw sugar beet juice to production of inverted liquid sugar. Applied Clay Science 102: 155–163. https://doi.org/10.1016/j.clay.2014.09.036.

Kochergin, V., and O. Tzschatzsch. 2005. Ion exchange thin juice softening using fractal technology. International Sugar Journal 107 (1278): 342–353.

Ma, X., D. Li, Z. Wu, H. Zhang, X. Chen, and Z. Liu. 2016. Mercury removal by adsorption on pectin extracted from sugar beet pulp: optimization by response surface methodology. Chemical Engineering and Technology 39 (2): 371–377. https://doi.org/10.1002/ceat.201400059.

Mahvi, A.H., F. Gholami, and S. Nazmara. 2008. Cadmium biosorption from wastewater by Ulmus leaves and their ash. European Journal of Scientific Research 23 (2): 197–203.

Malekbala, M.R., S. Hosseini, S. Kazemi Yazdi, S. Masoudi Soltani, and M.R. Malekbala. 2012. The study of the potential capability of sugar beet pulp on the removal efficiency of two cationic dyes. Chemical Engineering Research and Design 90 (5): 704–712. https://doi.org/10.1016/j.cherd.2011.09.010.

Maravić, N., F. Kiss, L. Šereš, B. Bogdanović, B. Bogdanović, and Z. Šereš. 2015. Economic analysis and LCA of an advanced industrial-scale raw sugar juice purification procedure. Food and Bioproducts Processing 95: 19–26. https://doi.org/10.1016/j.fbp.2015.02.004.

Maravić, N., Z. Šereš, S. Vidović, A. Mišan, I. Milovanović, R. Radosavljević, and B. Pavlić. 2018. Subcritical water hydrolysis of sugar beet pulp towards production of monosaccharide fraction. Industrial Crops and Products 115: 32–39. https://doi.org/10.1016/j.indcrop.2018.02.014.

Maravić, N. 2019. Stabilizujući efekat polisaharidnih jedinejnja industrije šećera u proizvodnji emulzija. Stabilizing effect of sugar industry polysaccharide compounds in the production of emulsions. Doctoral Thesis, University of Novi Sad.

Mgombezi, D., and M.R. Vegi. 2020. An investigation on effectiveness of grafted potato starch as an adsorbent for hard water treatment. Journal of Chemistry. https://doi.org/10.1155/2020/4050862.

Mladenović, D., J. Pejin, S. Kocić-Tanackov, Ž Radovanović, A. Djukić-Vuković, and L. Mojović. 2018. Lactic acid production on molasses enriched potato stillage by Lactobacillus paracasei immobilized onto agro-industrial waste supports. Industrial Crops and Products 124: 142–148. https://doi.org/10.1016/j.indcrop.2018.07.081.

Ӧzer, A., and F. Tumen. 2003. Cd (II) adsorption from aqueous solution by activated carbon from sugar beet pulp impregnated with phosphoric acid. Fresenius Environmental Bulletin 12 (9): 1050–1058.

Pehlivan, E., B.H. Yanik, G. Ahmetli, and M. Pehlivan. 2008. Equilibrium isotherm studies for the uptake of cadmium and lead ions onto sugar beet pulp. Bioresource Technology 99 (9): 3520–3527. https://doi.org/10.1016/j.biortech.2007.07.052.

Peić Tukuljac, L., J. Krulj, L. Pezo, N. Maravić, J. Kojić, and Z. Šereš. 2022. Utilization of sugar beet pulp as biosorbent for molassigenic metal ions: kinetic study of batch biosorption. Periodica Polytechnica Chemical Engineering 66 (4): 629–640. https://doi.org/10.3311/PPch.19783.

Pinho, S.P., and E.A. Macedo. 2005. Solubility of NaCl, NaBr, and KCl in water, methanol, ethanol, and their mixed solvents. Journal of Chemical and Engineering Data 50 (1): 29–32. https://doi.org/10.1021/je049922y.

Reddad, Z., C. Gérente, Z. Andrès, M.C. Ralet, J.F. Thibault, and P.L. Cloirec. 2002. Ni(II) and Cu(II) binding properties of native and modified sugar beet pulp. Carbohydrate Polymers 49 (1): 23–31. https://doi.org/10.1016/S0144-8617(01)00301-0.

Šćiban, M., T. Vulic, D. Kukic, J. Prodanovic, and M. Klasnja. 2016. Characterization of raw and treated sugar beet shreds for copper ions adsorption. Desalination and Water Treatment 57 (31): 14590–14597. https://doi.org/10.1080/19443994.2015.1067167.

Van der Poel, P.W. 1998. Sugar technology. Beet and cane sugar manufacture. Berlin: Verlag Dr. Albert Bartens KG.

Vasudevan, P., V. Padmavathy, and S.C. Dhingra. 2002. Biosorption of monovalent and divalent ions on baker’s yeast. Bioresource Technology 82 (3): 285–289. https://doi.org/10.1016/S0960-8524(01)00181-X.

Worch, E. 2012. Adsorption technology in water treatment fundamentals, processes, and modeling. Berlin: Walter, W. de Gruyter.

Acknowledgements

This research is financed by The Ministry of Education, Science and Technological Development (Serbia), project No. 451-03-68/2022-14/200222. The authors would like to acknowledge the support from Ministry of Education, Science and Technological Development (Serbia) for the textural analysis, project No. 451-03-68/2022-14/200134.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Lidija Peić Tukuljac was involved in investigation, writing—original draft, methodology; Jelena Krulj helped in conceptualization, writing—original draft; Jovana Kojić contributed to validation, writing—review & editing; Jelena Šuran was involved in investigation; Marija Bodroža-Solarov helped in visualization, funding acquisition; Bojan Miljević contributed to investigation; Zita Šereš was involved in conceptualization, methodology; Nikola Maravić helped in conceptualization, methodology, writing—review & editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peić Tukuljac, L., Krulj, J., Kojić, J. et al. Biosorption of Na+, K+ and Ca2+ from Alkalized Sugar Juice by Unmodified Pressed Sugar Beet Pulp in Closed-Loop Column System. Sugar Tech 25, 766–776 (2023). https://doi.org/10.1007/s12355-022-01234-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01234-z